Ignoto,

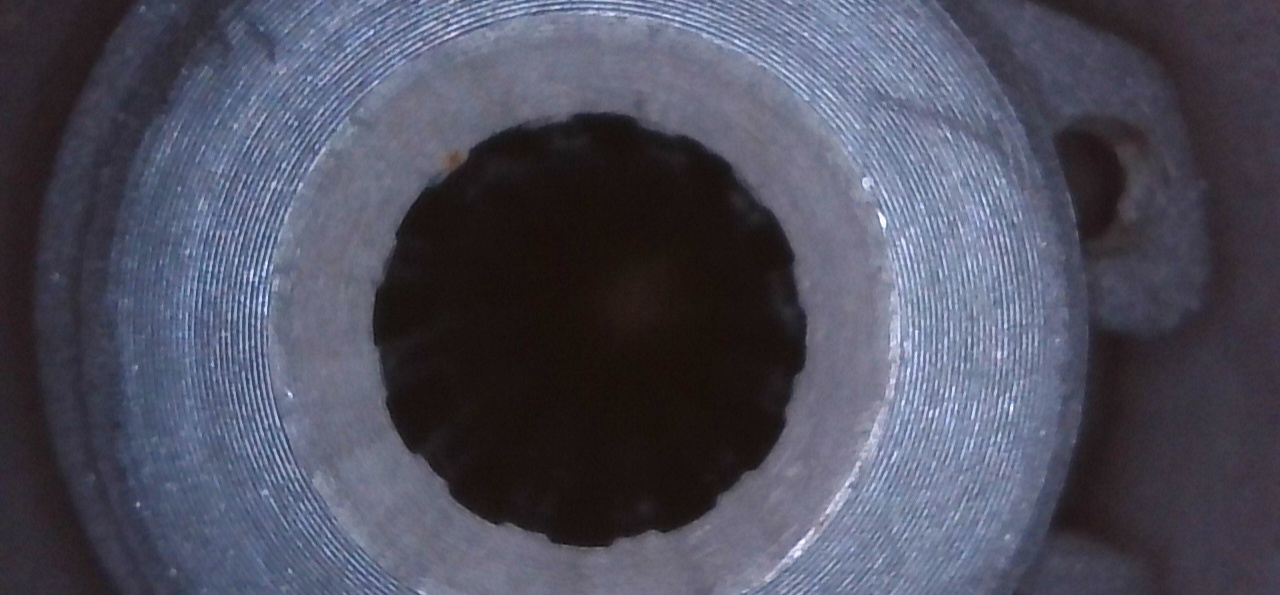

What appears to be lead streaks on the lands near the crown is probably damage caused by the crowning tool pilot. Cutting the barrel shorter and recrowning seems like the only way to fix this.

One aspect to consider is if the barrel muzzle is chocked and if that is required to shoot well. Perhaps less of a consideration, considering the barrel is not shooting well. Before you cut the barrel, or do anything to the muzzle, also check the breech end for burrs or sharp edges that can damage the pellets on loading. This guide may be very useful indiagnosing barrel trouble, and on how to fix it:

The following article is intended for the do-it-yourselfer that is interested in either finding and fixing a problem with a barrel, or improving the accuracy of an already good performer. You don't have to be a master machinist to get excellent results. The techniques described here can be...

www.airgunnation.com

If you recrown the barrel then you need to align to the bore and not the barrel OD. We like to think these are the same, but often they are not. If picking up and running true to the bore is difficult, then simply parting off the barrel, and then using a sharp lathe tool to cut a flat crown, from the inside to the outside, can minimize any burr formed. Cutting from the outside in maximizes the burr into the bore, and should not be the last process used.

The flat crown is the most forgiving of air flow when concentricity is suspect. The very edge of that 90 degree edge can be lightly chamfered by means of a round brass screw head and 400 grit lapping compound. Finer or rougher lapping compound can also work. The screw head sperical diameter should be about twice the caliber that you are recrowning. The screw is spun in a hand drill, Dremel or similar hand tool, while the barrel is spun slowly in a lathe in the opposite direction. An orbital motion is used while lightly holding the hand drill, so that the brass screw head does not form a groove in one location. The drill motion is similar to the way curved lenses are ground.

It is possible to perform this brass screw lapping with the barrel pointing up, in a vice, or still attached to the airgun. In any event, push a cleaning pellet or wad of felt or tissue into the bore perhaps 10 mm below the crown, to prevent lapping compound from travelling down the barrel. After you are done, blow the wad out from the breech end with compressed air. Follow up with a few more oil wetted cleaning pellets to wipe out the residue so you can inspect the crown.

It actually takes very little time to produce a functional crown using the brass screw method. They key is to keep the screw in contact with the muzzle so it does not chatter. Yet, use such low pressure that the lapping compound does the cutting, rather than trying to displace steel by contact pressure.

It may help if you push pellets through the bore to see if they are tight or loose in some parts of your barrel; or if they catch. This should be done from the breech, which may mean removing the barrel from the action, unless the bolt or probe can be removed. If the pellets are loose down the barrel, then you may need to find some with a larger head diameter to shoot well. Ditto for slugs. The projectile should not rattle down the barrel.

If the breech is tight or sharp, that can cause loading force to be so high that it distorts or shaves the projectile. Which would make it shoot poorly. So, it is important to diagnose all the potential causes for poor grouping and then address them appropriately, rather than assuming the crown is the only potential problem.

Be careful about overtightening the barrel retention screws on reassembly, as that can spring the barrel bore out of round. Or dent the barrel if the screws have sharp points to located in dimples. Better to just "nip" the screws lightly, then apply wicking Loctite to prevent them from coming loose. You should also check the inside of the barrel opposite the retention screw locations for any deformation when you check the rest of the bore.

Read the barrel trouble shooting thread, linked above, before you do anything. It contains lots of useful information.