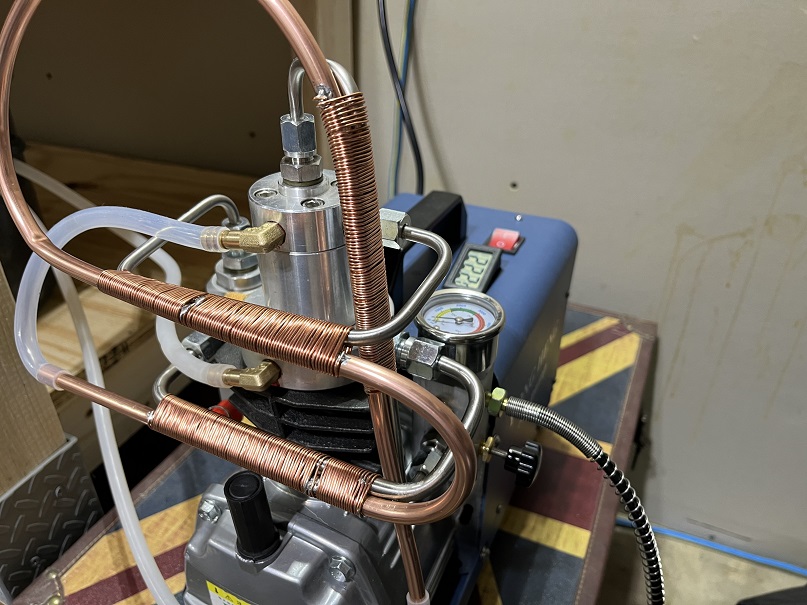

After a little 2nd degree burn on my arm from one of the tubes on my YH, I decided to add a little water cooling. I cannot take credit for the idea. I saw this the Target Forge YT channel https://www.youtube.com/watch?v=rcI1wD_rXOg&t=962s I just went crazy and wrapped all three YH tubes.

I started by bending some Amazon tubing brake line by hand. I wanted to get the basic shape as best as I could. I tried to minimize bends and keep the length of the tubing minimized.

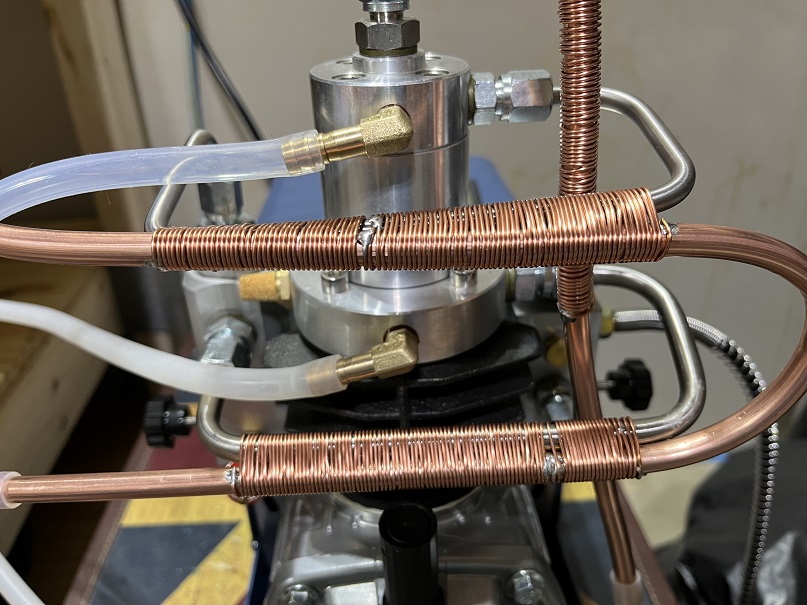

Once I got the routing figured out, I wrapped copper wire snug as I could around the YH tube and the copper plated brake line. The copper wire is an excellent thermal conductor and will help shunt the heat off the YH lines.

I attached the copper wire to the brake line with solder. I ran short a few spots on the wire, so I just soldered the loose end and started a new run and kept wrapping. I did not remove any of the YH tubing to wrap the copper wire. It was a little challenging wrapping but I managed. I did take off the oil breather to get a little more room while wrapping.

I bought some Amazon silicon tubing to help with water attachments. I only needed less than a foot but I am going to use the extra for spare cooling line.

It will help with condensing the moisture too, keeping it out of my guns. It took less than 2hrs of total labor time and less than $45 in materials. Its not perfect and I'm not mechanically inclined but it meets my needs.

Any questions let me know.

Navyblue/Steve

I started by bending some Amazon tubing brake line by hand. I wanted to get the basic shape as best as I could. I tried to minimize bends and keep the length of the tubing minimized.

Once I got the routing figured out, I wrapped copper wire snug as I could around the YH tube and the copper plated brake line. The copper wire is an excellent thermal conductor and will help shunt the heat off the YH lines.

I attached the copper wire to the brake line with solder. I ran short a few spots on the wire, so I just soldered the loose end and started a new run and kept wrapping. I did not remove any of the YH tubing to wrap the copper wire. It was a little challenging wrapping but I managed. I did take off the oil breather to get a little more room while wrapping.

I bought some Amazon silicon tubing to help with water attachments. I only needed less than a foot but I am going to use the extra for spare cooling line.

It will help with condensing the moisture too, keeping it out of my guns. It took less than 2hrs of total labor time and less than $45 in materials. Its not perfect and I'm not mechanically inclined but it meets my needs.

Any questions let me know.

Navyblue/Steve