So you want a .177 Cayden… and they only come in .22…

I recently bought this Reximex Daystar .177 from an AGN member via the classifieds here. It is essentially a Benjamin Cayden .177 – with a nicer shaped stock than a Cayden, IMHO.

It was bought for his wife, owned briefly and sold to me – she wanted a 12 ft/lb rifle.

I can see why she didn’t like the Daystar out-of-the-box…

…I cleaned the barrel filled to 250 bar and took 28 shots (2 magazines). It was shooting 10.5g pellets at 1,025 fps (with the “power adjuster” – transfer port restrictor on full open). It went from 250 to 190 bar on those 28 shots – so it was using a massive 31psi per shot – for 10.5g .177 !

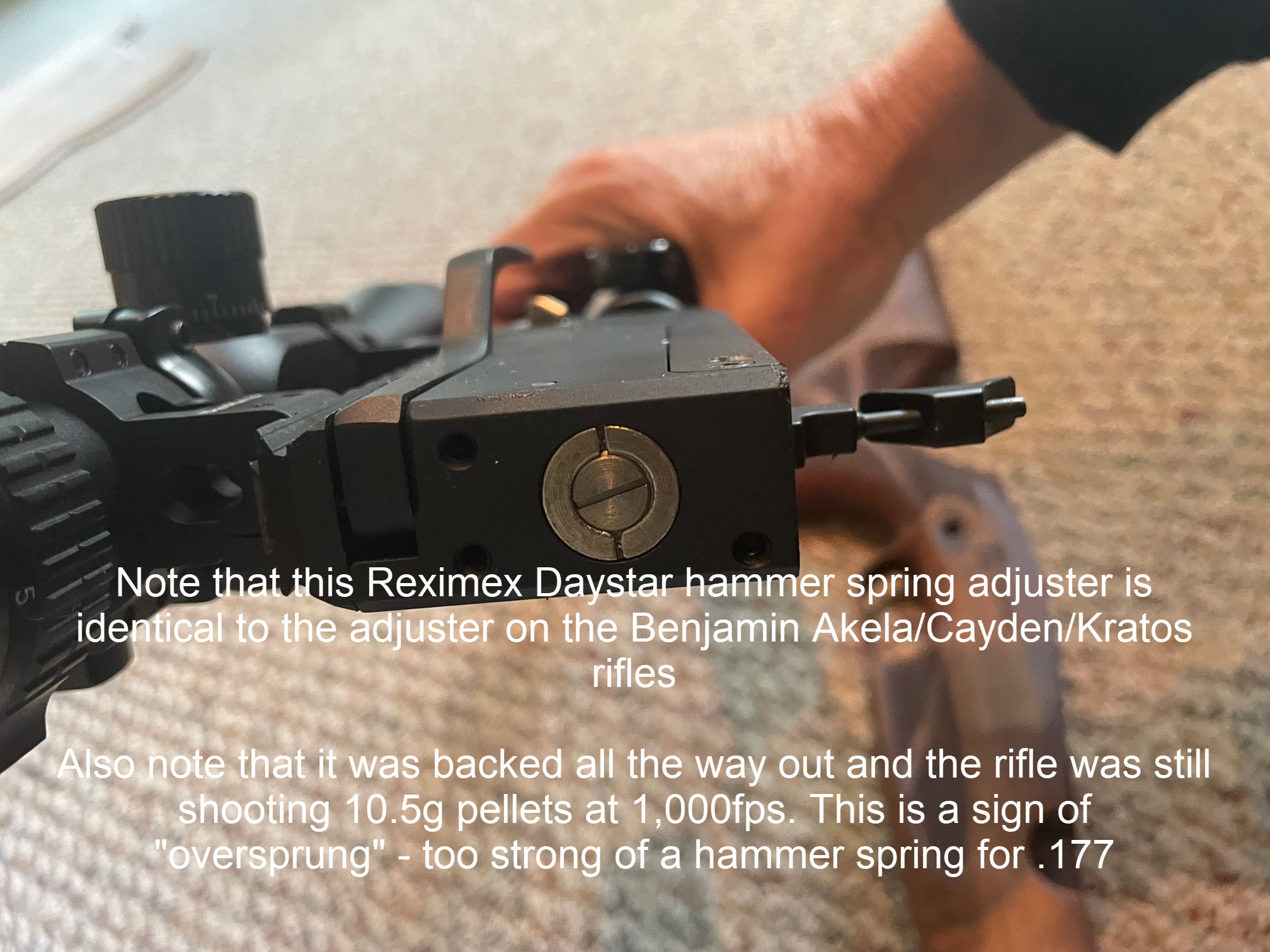

Needless to say, with the hammer hitting the valve that hard it was loud and felt “loud”. It also had an “elephant” 2.2 pound trigger pull weight !! Turning down the “power adjuster” would reduce velocity – but not improve efficiency or loudness, as the hammer was still pounding the valve hard with each shot…

I have extensive experience with tuning these rifles, so I took off the stock (one bolt) and checked – sure enough the hammer spring adjustment screw was backed all the way out – and the rifle was still shooting WAY to fast. It was obviously oversprung – just like the Benjamin Akela / Cayden / Kratos are. I guess it’s Kral’s concession to marketing to put these oversize hammer springs in their rifles – so they can advertise “big power”.

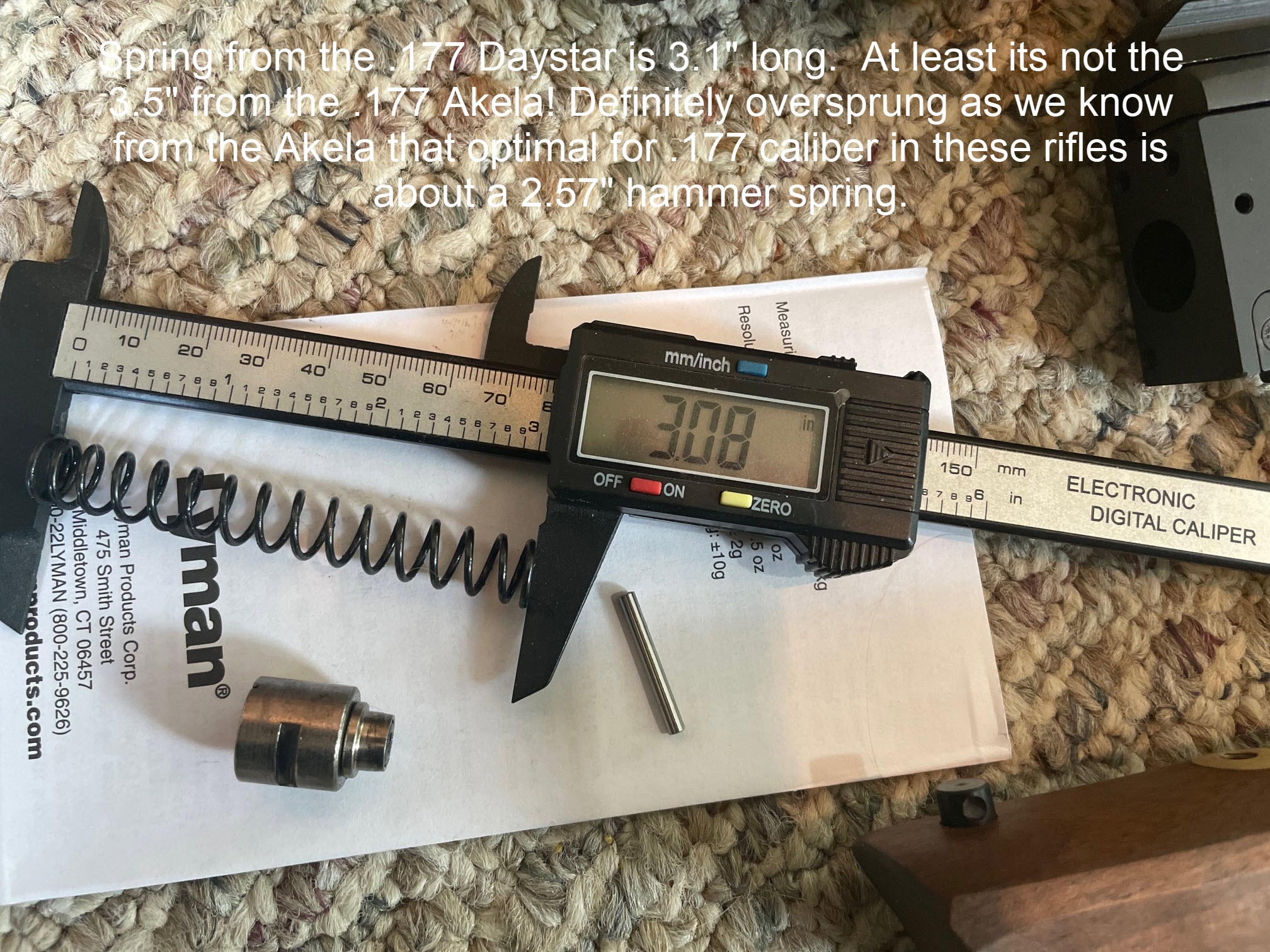

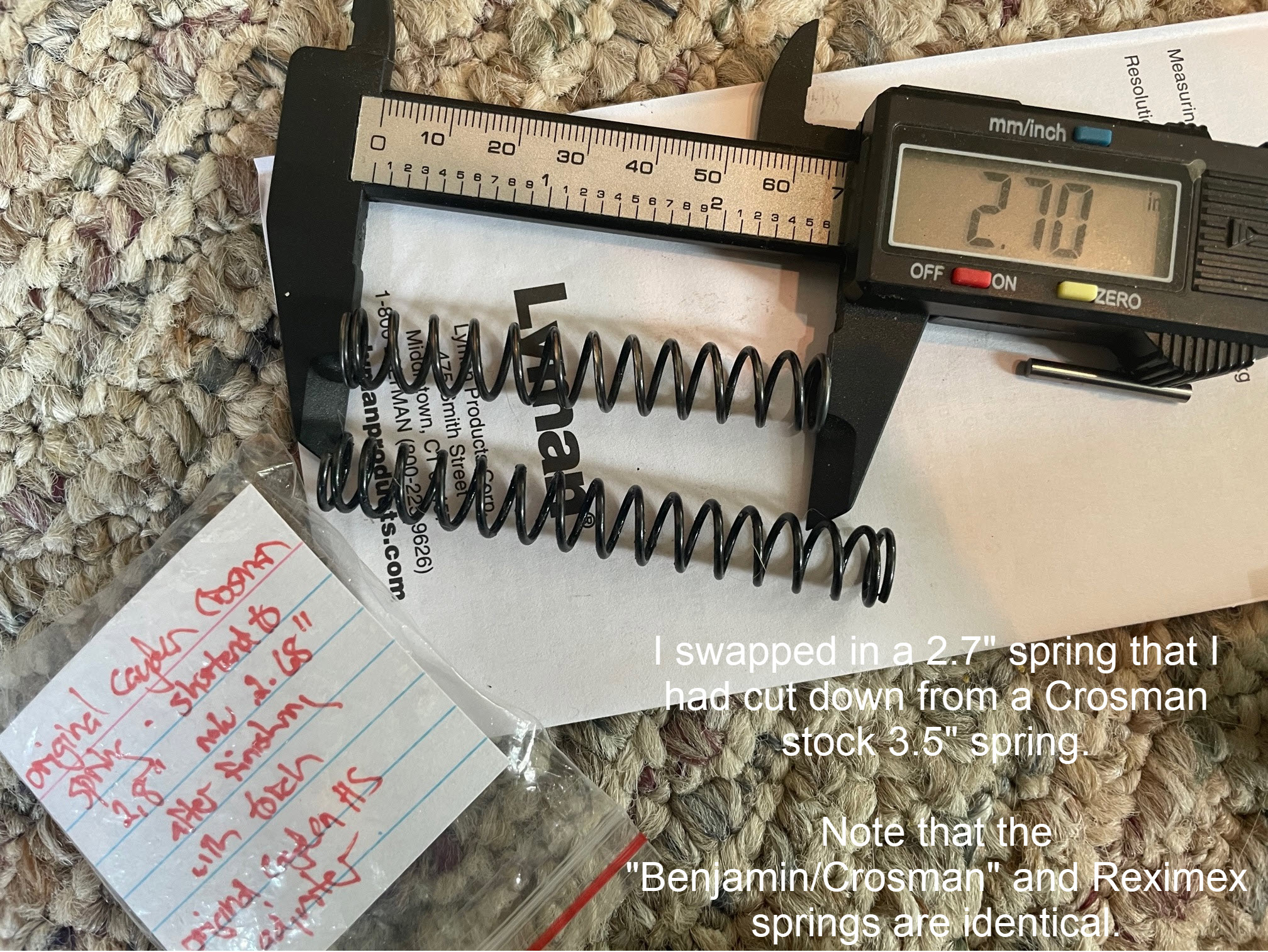

I knocked out the pin, popping out the adjuster and hammer spring. The spring measured 3.1”. At least it was shorter than the crazy 3.5” long spring that comes in the .177 Akela. As you can see in the pictures, the spring is identical in diameter and wire thickness to the Benjamin springs – not surprising as they all come from the same factory (made by Kral).

I was on my lunch hour, so popped in a 2.7” spring that I had cut down for my Cayden (I’m currently using a custom spring I made in my Cayden). I would have used a 2.57” spring – as I know that is about optimal for .177 in these rifles – but I didn’t have one handy – and I wanted to do a quick trigger job during lunch. Eventually I will put in a 2.57” spring.

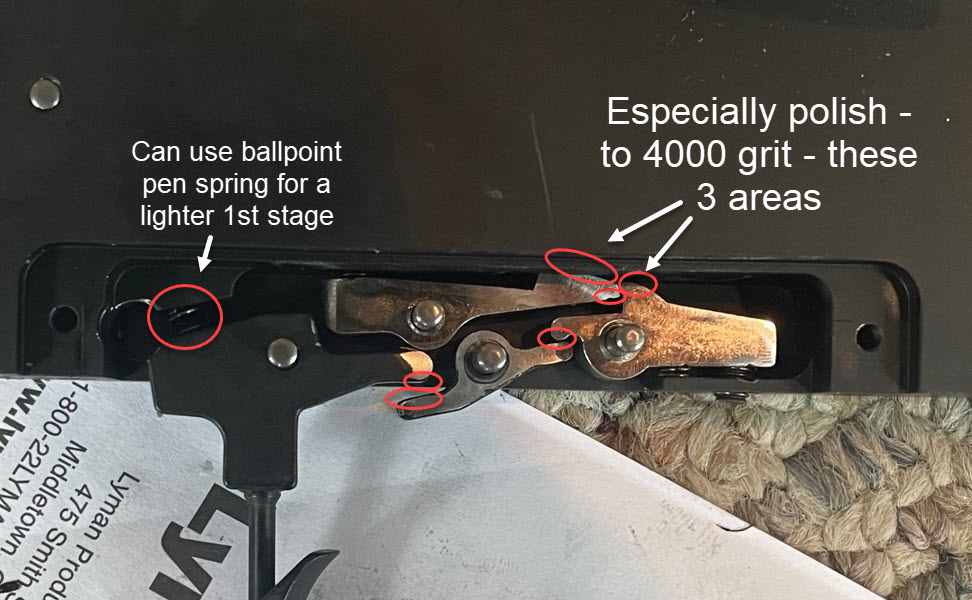

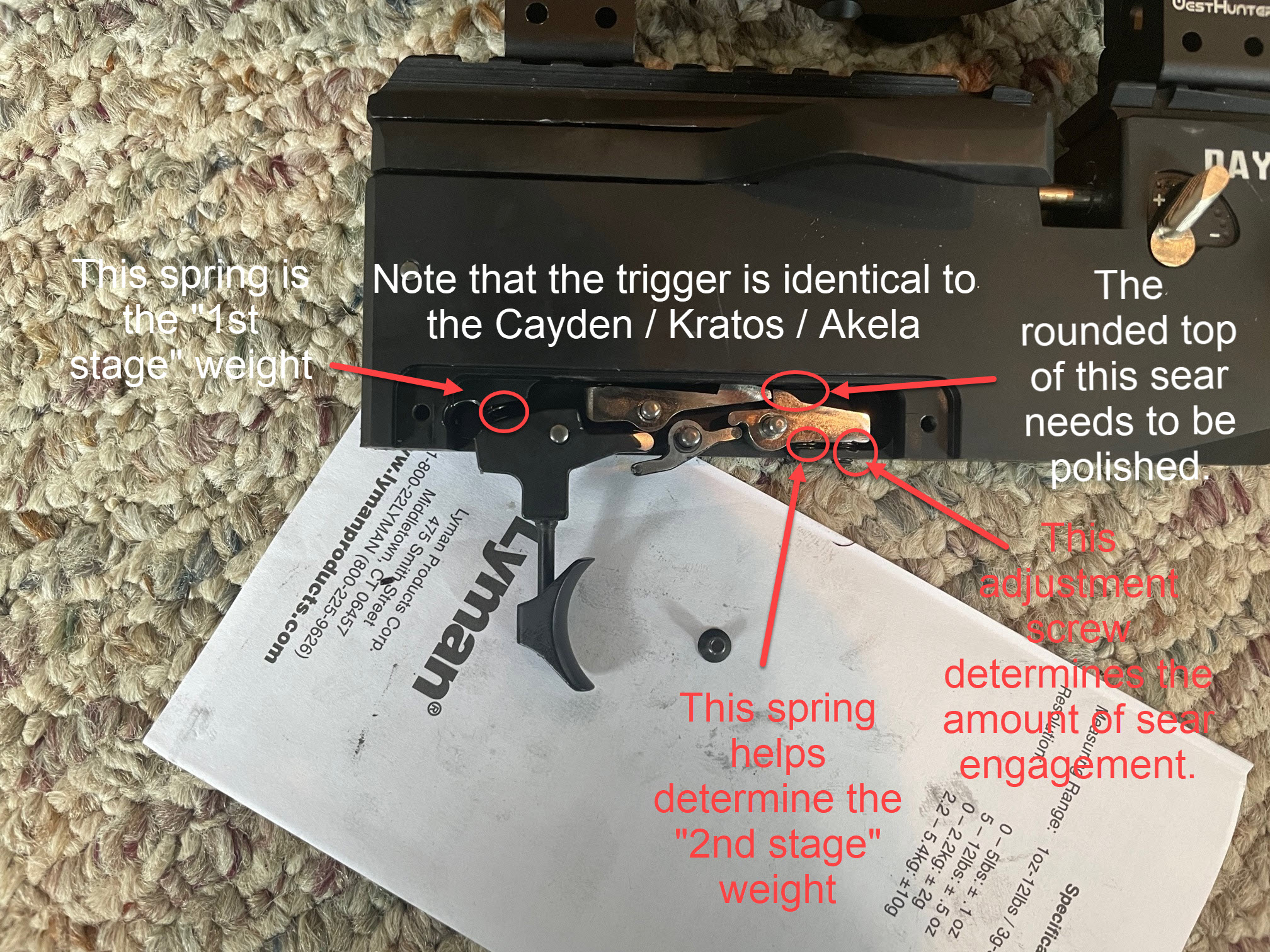

As the pictures show, the trigger is identical to the Cayden / Akela / Kratos. It’s a very nice trigger, once you polish up the contact points and adjust the sear engagement. This Reximex Daystar was finished a bit nicer on the trigger than the Benjamin rifles, as a couple of the components didn’t have the black stuff on them – they at least were semi shiny steel. I used my Dremmel to get rid of all the black coating and polish up the key contact areas to 3000 grit (mirror like).

After the polish, I was able to adjust the trigger pull weight down to about 15 ounces – turning in the adjustment screw until it wouldn’t cock and then slightly backing it off till it cocked. I like 6 ounces – so I cut ½ a coil from the end of the “1st stage” spring by the trigger and 1/3 coils (just a tiny bit) from the 2nd stage spring. Amazing difference – I was able to get down to a consistent 2.8 ounces (!) – and still pass the bump test ! I backed to off to about 4.8 ounces. Done for a quick first “trigger tune”. Everything took 1 hour. (I may go back to the 2.8 ounces – it felt freakin’ awesome).

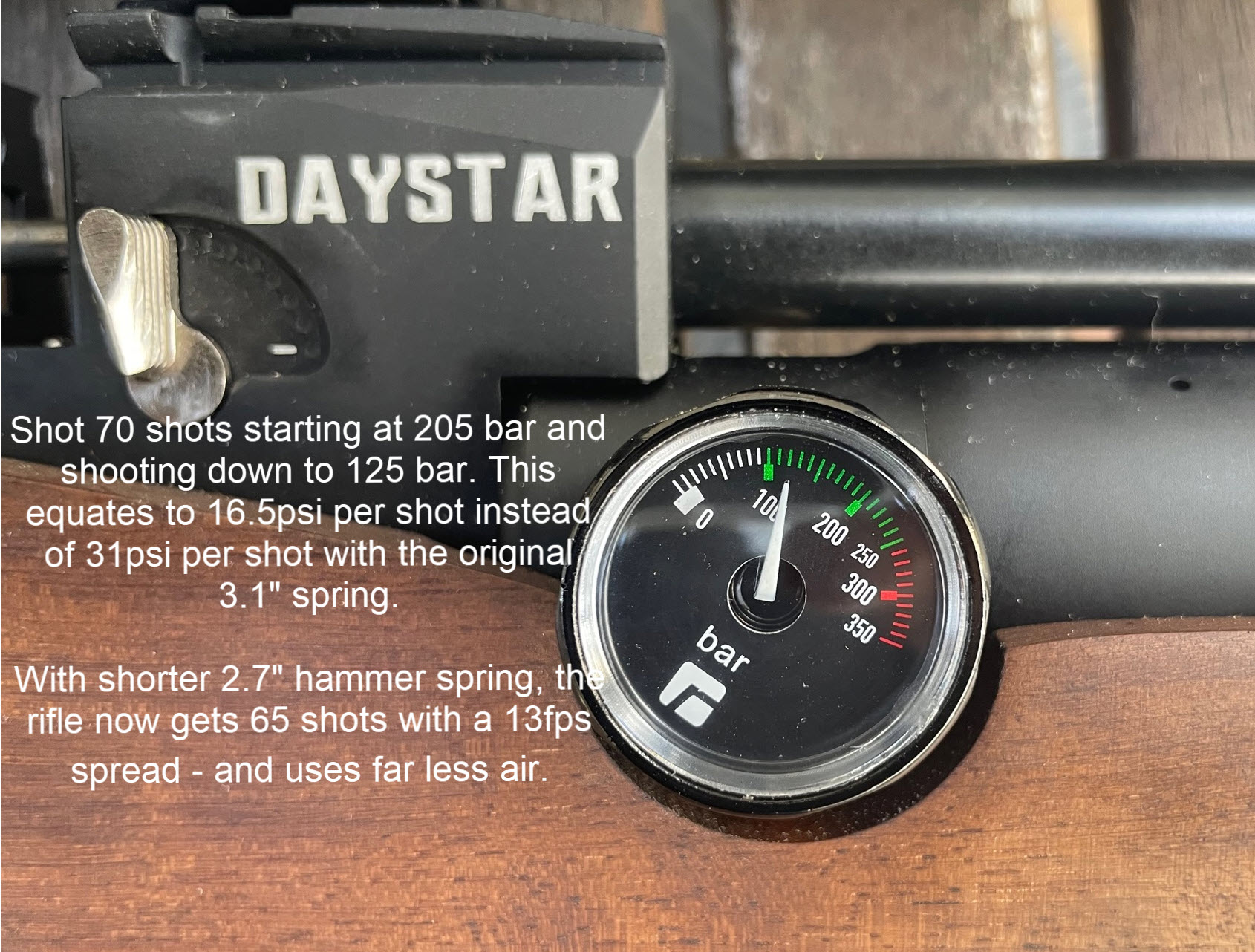

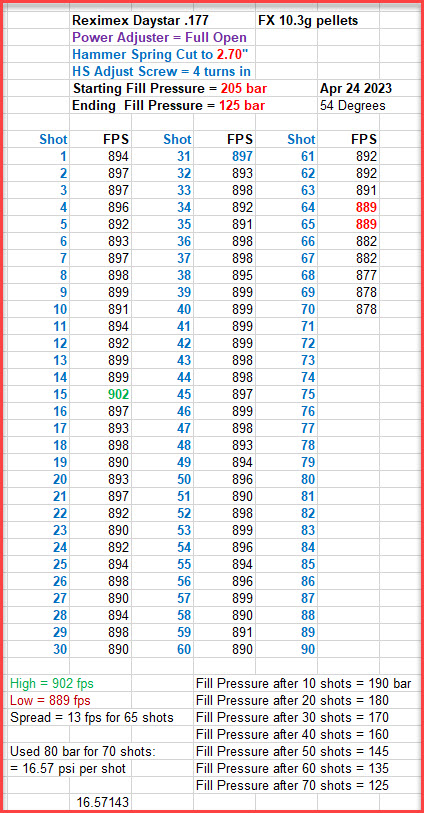

After work I shot 7 ten shot groups – filling to just 205bar and shooting down to 125 bar. That’s 70 shots using 80bar – this equates to 16.5 psi per shot. So by cutting the spring from 3.1” to 2.7”, the efficiency improved from 31 psi per shot to 16.5 psi per shot – roughly double the efficiency with that quick change. I know from experience that using a 2.57” spring with .177 in these rifles will give an efficiency of about 11.5 psi per shot (shooting 10.3g pellets at 890fps).

Note that the 1st 65 shots had a 13 fps spread !! The rifle’s sound volume was MUCH quieter – as it was using ½ the air per shot now.

Also, I will try filling above the 205bar that I used for the shot string (max fill is 250 bar !) – I may be able to get 90+ shots with a less than 20fps spread – with the 2.7” spring (and well over 100 shots with the proper 2.57” spring).

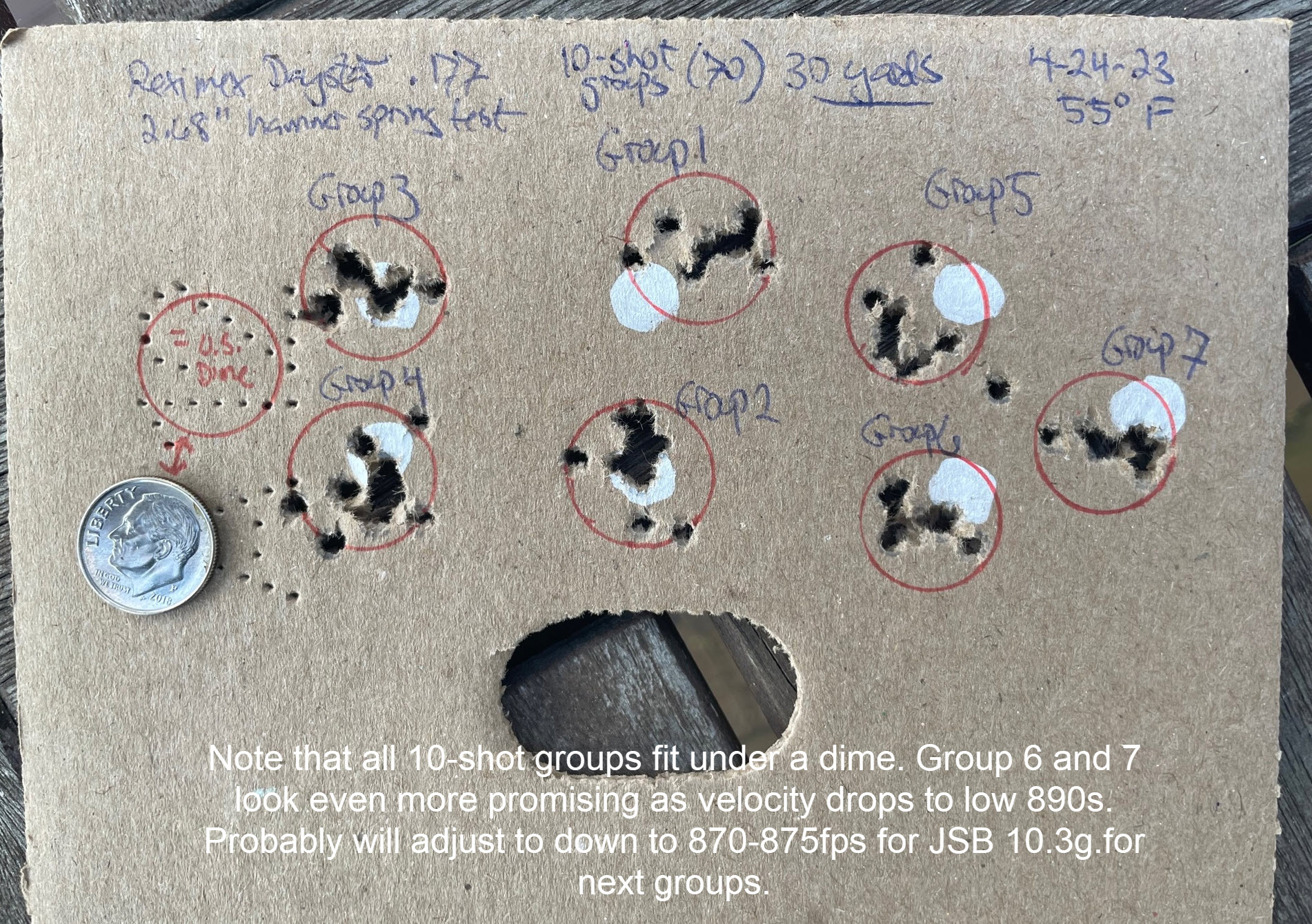

As you can see, the 10-shot groups were all under a dime (one flyer). Groups 6 and 7 were getting tighter as the velocity dropped into the lower 890s. Next groups I’ll try shooting 870 fps – and see if the groups get tighter.

Finally, check out the tiger stripes on the Turkish walnut stock. I’ll strip the factory finish off and then hand rub in an oil finish with Tru-Oil – and this thing will look incredible !!

These rifles are super simple to work on, cost under $500 on sale and are very reliable (due to their simple design). Being unregulated, you still get an awesome flat shot string (even this quick tune got me 65 shots with a 13 fps spread) – better than many/most sub $500 rifles WITH regulators. These Krals have excellent valving and great triggers (once you polish them up). The power adjuster on this Daystar has detents and works very nicely. The barrels are accurate. I’d highly recommend these rifles to anyone getting into PCPs or for a reliable hunting rifle.

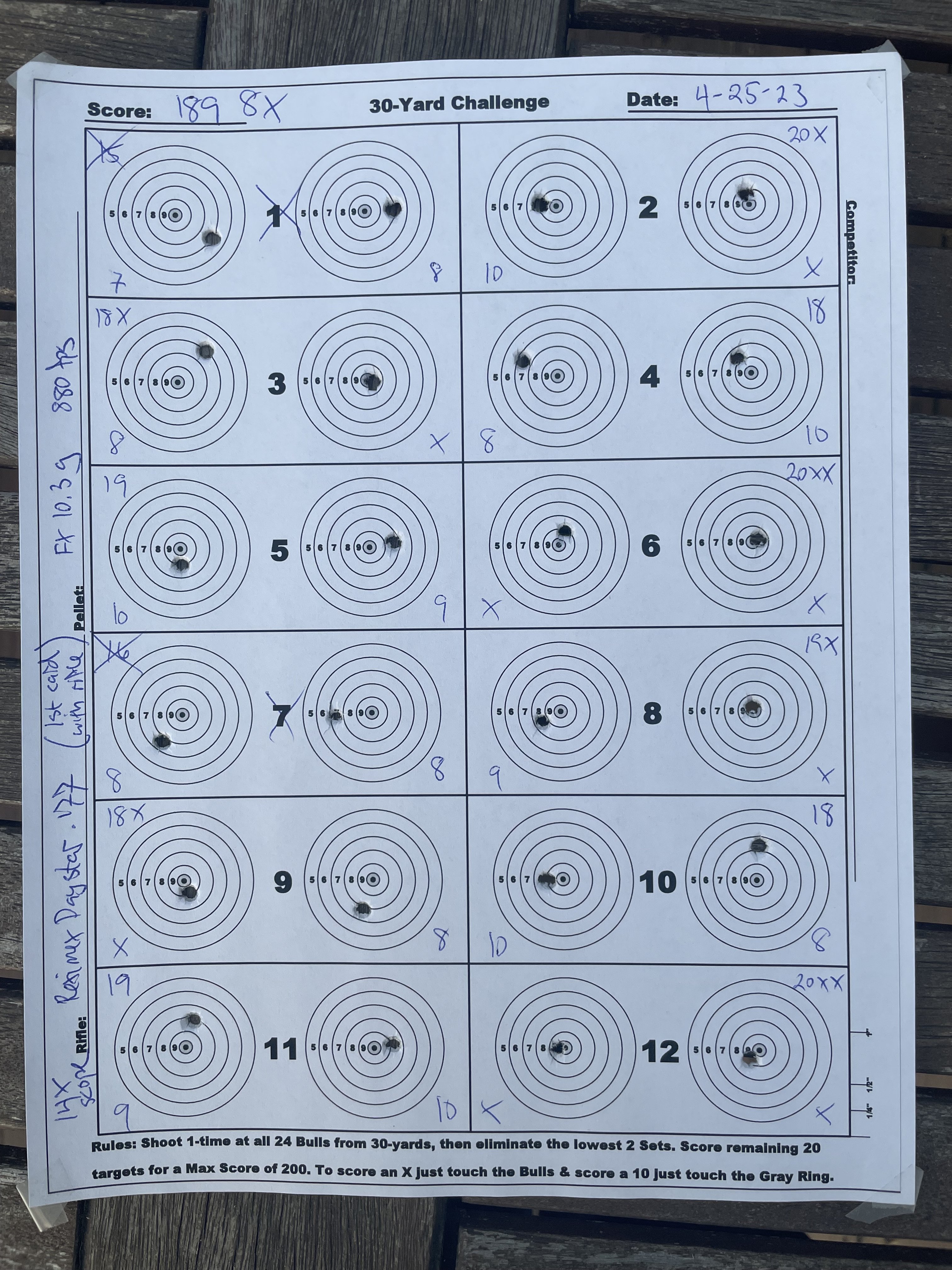

I use them for target shooting – I’ve scored 198 with the Cayden and 192 with the Akela in the “30 Yard Challenge” on AGN damn good accuracy.

I shot my 1st 30 Yard Challenge card with the Daystar tonight after work - using just a 14x scope… 189 8X … not bad since I’ve got less than 150 shots on the rifle.

-Ed

I recently bought this Reximex Daystar .177 from an AGN member via the classifieds here. It is essentially a Benjamin Cayden .177 – with a nicer shaped stock than a Cayden, IMHO.

It was bought for his wife, owned briefly and sold to me – she wanted a 12 ft/lb rifle.

I can see why she didn’t like the Daystar out-of-the-box…

…I cleaned the barrel filled to 250 bar and took 28 shots (2 magazines). It was shooting 10.5g pellets at 1,025 fps (with the “power adjuster” – transfer port restrictor on full open). It went from 250 to 190 bar on those 28 shots – so it was using a massive 31psi per shot – for 10.5g .177 !

Needless to say, with the hammer hitting the valve that hard it was loud and felt “loud”. It also had an “elephant” 2.2 pound trigger pull weight !! Turning down the “power adjuster” would reduce velocity – but not improve efficiency or loudness, as the hammer was still pounding the valve hard with each shot…

I have extensive experience with tuning these rifles, so I took off the stock (one bolt) and checked – sure enough the hammer spring adjustment screw was backed all the way out – and the rifle was still shooting WAY to fast. It was obviously oversprung – just like the Benjamin Akela / Cayden / Kratos are. I guess it’s Kral’s concession to marketing to put these oversize hammer springs in their rifles – so they can advertise “big power”.

I knocked out the pin, popping out the adjuster and hammer spring. The spring measured 3.1”. At least it was shorter than the crazy 3.5” long spring that comes in the .177 Akela. As you can see in the pictures, the spring is identical in diameter and wire thickness to the Benjamin springs – not surprising as they all come from the same factory (made by Kral).

I was on my lunch hour, so popped in a 2.7” spring that I had cut down for my Cayden (I’m currently using a custom spring I made in my Cayden). I would have used a 2.57” spring – as I know that is about optimal for .177 in these rifles – but I didn’t have one handy – and I wanted to do a quick trigger job during lunch. Eventually I will put in a 2.57” spring.

As the pictures show, the trigger is identical to the Cayden / Akela / Kratos. It’s a very nice trigger, once you polish up the contact points and adjust the sear engagement. This Reximex Daystar was finished a bit nicer on the trigger than the Benjamin rifles, as a couple of the components didn’t have the black stuff on them – they at least were semi shiny steel. I used my Dremmel to get rid of all the black coating and polish up the key contact areas to 3000 grit (mirror like).

After the polish, I was able to adjust the trigger pull weight down to about 15 ounces – turning in the adjustment screw until it wouldn’t cock and then slightly backing it off till it cocked. I like 6 ounces – so I cut ½ a coil from the end of the “1st stage” spring by the trigger and 1/3 coils (just a tiny bit) from the 2nd stage spring. Amazing difference – I was able to get down to a consistent 2.8 ounces (!) – and still pass the bump test ! I backed to off to about 4.8 ounces. Done for a quick first “trigger tune”. Everything took 1 hour. (I may go back to the 2.8 ounces – it felt freakin’ awesome).

After work I shot 7 ten shot groups – filling to just 205bar and shooting down to 125 bar. That’s 70 shots using 80bar – this equates to 16.5 psi per shot. So by cutting the spring from 3.1” to 2.7”, the efficiency improved from 31 psi per shot to 16.5 psi per shot – roughly double the efficiency with that quick change. I know from experience that using a 2.57” spring with .177 in these rifles will give an efficiency of about 11.5 psi per shot (shooting 10.3g pellets at 890fps).

Note that the 1st 65 shots had a 13 fps spread !! The rifle’s sound volume was MUCH quieter – as it was using ½ the air per shot now.

Also, I will try filling above the 205bar that I used for the shot string (max fill is 250 bar !) – I may be able to get 90+ shots with a less than 20fps spread – with the 2.7” spring (and well over 100 shots with the proper 2.57” spring).

As you can see, the 10-shot groups were all under a dime (one flyer). Groups 6 and 7 were getting tighter as the velocity dropped into the lower 890s. Next groups I’ll try shooting 870 fps – and see if the groups get tighter.

Finally, check out the tiger stripes on the Turkish walnut stock. I’ll strip the factory finish off and then hand rub in an oil finish with Tru-Oil – and this thing will look incredible !!

These rifles are super simple to work on, cost under $500 on sale and are very reliable (due to their simple design). Being unregulated, you still get an awesome flat shot string (even this quick tune got me 65 shots with a 13 fps spread) – better than many/most sub $500 rifles WITH regulators. These Krals have excellent valving and great triggers (once you polish them up). The power adjuster on this Daystar has detents and works very nicely. The barrels are accurate. I’d highly recommend these rifles to anyone getting into PCPs or for a reliable hunting rifle.

I use them for target shooting – I’ve scored 198 with the Cayden and 192 with the Akela in the “30 Yard Challenge” on AGN damn good accuracy.

I shot my 1st 30 Yard Challenge card with the Daystar tonight after work - using just a 14x scope… 189 8X … not bad since I’ve got less than 150 shots on the rifle.

-Ed

Last edited: