At the RMAC while talking with Jim at the precision seminar he put on I learned something new, to me. When setting up my scopes I use a Wheeler Level kit. Jim told me always use the hanging string method to level the reticle because scope manufactures have a plus or minus 3 degrees tollarence. So when I returned leveled up my guns and hung a string and sure enough. Could see diferent cants that didn't agree with the level. sylvan

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Scope Reticle

- Thread starter Kitplanenut

- Start date

At the RMAC while talking with Jim at the precision seminar he put on I learned something new, to me. When setting up my scopes I use a Wheeler Level kit. Jim told me always use the hanging string method to level the reticle because scope manufactures have a plus or minus 3 degrees tollarence. So when I returned leveled up my guns and hung a string and sure enough. Could see diferent cants that didn't agree with the level. sylvan

Describe the method. You hang a string from where? How do you compare the string's attitude to that of the reticle? TIA

Upvote 0

Like this?: https://www.youtube.com/watch?v=lQGM8Cn8lS8&app=desktop 2:10 in. BTW, "torch" is Britspeak for flashlite.

Upvote 0

Here’s an easy way to eliminate cant errors without the benefit of special tools. All you need is a mirror. Set the mirror at a distance of, say, 5 yards and set your AO to 10 yards. Look through the scope at your reflection in the mirror. Twist the scope in the mounts until the vertical bar of the reticle simultaneously bisects both the muzzle and objective bell. Then lock it down. At this point you have eliminated scope cant.

Now to eliminate rifle cant, install and use a level. View a known good plumb line (e.g. hanging string) through the scope and orient the rifle so it precisely aligns to it. Now affix your level so it shows level. From now on when you're shooting, hold the rifle so it shows level and you can be sure you've eliminated both potential sources of cant error.

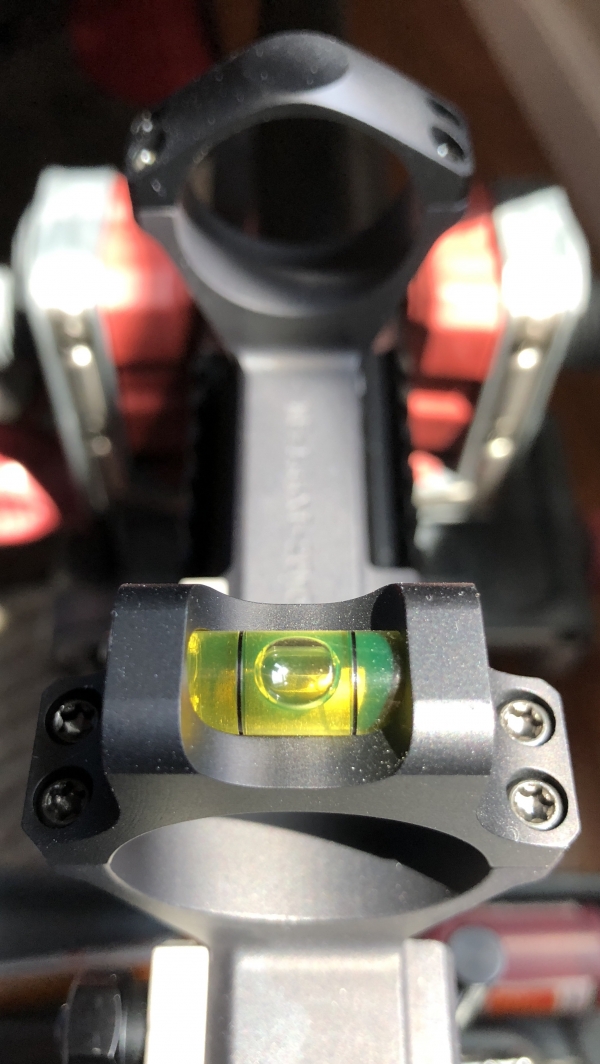

By the way, don't buy a level that attaches to the scope rail. There is no guarantee it will show level. Instead, get one that attaches to the scope tube so you can rotate it and lock it down where it shows the proper level.

Now to eliminate rifle cant, install and use a level. View a known good plumb line (e.g. hanging string) through the scope and orient the rifle so it precisely aligns to it. Now affix your level so it shows level. From now on when you're shooting, hold the rifle so it shows level and you can be sure you've eliminated both potential sources of cant error.

By the way, don't buy a level that attaches to the scope rail. There is no guarantee it will show level. Instead, get one that attaches to the scope tube so you can rotate it and lock it down where it shows the proper level.

Upvote 0

So where do you place your level If there are no flat spots on your rifle? Say like a Prosport?

Upvote 0

I believe @josh3rd is asking about leveling the rifle. You can use a mount with a level, use a mount with a flat surface and an external level, or maybe the Pro Sport has a flat surface under the rifle say next to the trigger guard. You could also take the action out to get a flat surface.

In my (limited) experience, there is no need to over think it. Put the rifle in a stand, level it by eye, loosely mount scope, look through at something vertical or horizontal, tighten it down and call it a day. Even if you get it "perfect" when you mount it, you still have to match that accuracy when you shoot. As you know a spring rifle jumps around a bit too.

In my (limited) experience, there is no need to over think it. Put the rifle in a stand, level it by eye, loosely mount scope, look through at something vertical or horizontal, tighten it down and call it a day. Even if you get it "perfect" when you mount it, you still have to match that accuracy when you shoot. As you know a spring rifle jumps around a bit too.

Upvote 0

Okay, I think I see what you’re saying. But I would then ask, why is there any desire to “level the rifle? Or perhaps to be more clear, at what point in the scope installation process is there a reason to level against some surface?

The two things that matter are:

1. That the vertical bar of the reticle is aligned to the bore (specifically the muzzle).

2. That the reticle is held level when shooting

These two things deal with the two aspects of cant that sometimes get blurred together.

Item 1 deals with scope cant. That is, getting the right relationship between the scope and the barrel.

Item 2 deals with rifle cant. This refers to how one holds the rifle. But it should not be confused with holding it level relative to some flat surface on the rifle. That is why I’m careful to say in #2 above to hold the _reticle_ level rather than hold the rifle level. Because once we have the reticle aligned to the bore (#1), what matters is that the reticle is then held plumb / level. That is what ensures the projectile follows the vertical bar of the reticle based on the vertical force of gravity acting on it.

I will use an extreme example to illustrate the point. Imagine a scope mount that offsets the scope 1.5” inches to the left of the barrel. You could twist the scope in the rings counterclockwise until its reticle bisects the muzzle (eliminated scope cant via #1). You could then hold the rifle at about a 45deg clockwise angle to put the reticle level (eliminated rifle cant via #2) and you would have no cant error whatsoever. It would look absurd of course, holding it that way, but there would be no cant error.

Thankfully we don’t have to deal with errors of that magnitude but there are sources of error that get ignored when referencing to a flat surface somewhere on the rifle. Some examples are subtle offset error in the scope mounts (e.g. 3/8” rings used on 11mm rails, or vice versa), or dovetails milled at a slight angle to the barrel, or the receiver’s mortise bored at a slight angle, or a slightly bent barrel, etc.

That’s the quibble I have with many of the fancy gunsmithing jigs that make a level or plumb reference to some surface on the rifle that cannot necessarily be assumed to be valid. Meanwhile a mirror allows one to totally negate the sources of error.

The two things that matter are:

1. That the vertical bar of the reticle is aligned to the bore (specifically the muzzle).

2. That the reticle is held level when shooting

These two things deal with the two aspects of cant that sometimes get blurred together.

Item 1 deals with scope cant. That is, getting the right relationship between the scope and the barrel.

Item 2 deals with rifle cant. This refers to how one holds the rifle. But it should not be confused with holding it level relative to some flat surface on the rifle. That is why I’m careful to say in #2 above to hold the _reticle_ level rather than hold the rifle level. Because once we have the reticle aligned to the bore (#1), what matters is that the reticle is then held plumb / level. That is what ensures the projectile follows the vertical bar of the reticle based on the vertical force of gravity acting on it.

I will use an extreme example to illustrate the point. Imagine a scope mount that offsets the scope 1.5” inches to the left of the barrel. You could twist the scope in the rings counterclockwise until its reticle bisects the muzzle (eliminated scope cant via #1). You could then hold the rifle at about a 45deg clockwise angle to put the reticle level (eliminated rifle cant via #2) and you would have no cant error whatsoever. It would look absurd of course, holding it that way, but there would be no cant error.

Thankfully we don’t have to deal with errors of that magnitude but there are sources of error that get ignored when referencing to a flat surface somewhere on the rifle. Some examples are subtle offset error in the scope mounts (e.g. 3/8” rings used on 11mm rails, or vice versa), or dovetails milled at a slight angle to the barrel, or the receiver’s mortise bored at a slight angle, or a slightly bent barrel, etc.

That’s the quibble I have with many of the fancy gunsmithing jigs that make a level or plumb reference to some surface on the rifle that cannot necessarily be assumed to be valid. Meanwhile a mirror allows one to totally negate the sources of error.

Upvote 0

Okay, I think I see what you’re saying. But I would then ask, why is there any desire to “level the rifle? Or perhaps to be more clear, at what point in the scope installation process is there a reason to level against some surface?

The two things that matter are:

1. That the vertical bar of the reticle is aligned to the bore (specifically the muzzle).

2. That the reticle is held level when shooting

These two things deal with the two aspects of cant that sometimes get blurred together.

Item 1 deals with scope cant. That is, getting the right relationship between the scope and the barrel.

Item 2 deals with rifle cant. This refers to how one holds the rifle. But it should not be confused with holding it level relative to some flat surface on the rifle. That is why I’m careful to say in #2 above to hold the _reticle_ level rather than hold the rifle level. Because once we have the reticle aligned to the bore (#1), what matters is that the reticle is then held plumb / level. That is what ensures the projectile follows the vertical bar of the reticle based on the vertical force of gravity acting on it.

I will use an extreme example to illustrate the point. Imagine a scope mount that offsets the scope 1.5” inches to the left of the barrel. You could twist the scope in the rings counterclockwise until its reticle bisects the muzzle (eliminated scope cant via #1). You could then hold the rifle at about a 45deg clockwise angle to put the reticle level (eliminated rifle cant via #2) and you would have no cant error whatsoever. It would look absurd of course, holding it that way, but there would be no cant error.

Thankfully we don’t have to deal with errors of that magnitude but there are sources of error that get ignored when referencing to a flat surface somewhere on the rifle. Some examples are subtle offset error in the scope mounts (e.g. 3/8” rings used on 11mm rails, or vice versa), or dovetails milled at a slight angle to the barrel, or the receiver’s mortise bored at a slight angle, or a slightly bent barrel, etc.

That’s the quibble I have with many of the fancy gunsmithing jigs that make a level or plumb reference to some surface on the rifle that cannot necessarily be assumed to be valid. Meanwhile a mirror allows one to totally negate the sources of error.

Everything you said is right on. The most important to learn is:

"The two things that matter are:

1. That the vertical bar of the reticle is aligned to the bore (specifically the muzzle).

2. That the reticle is held level when shooting"

#1 deals with scope cant. #2 deals with gun cant. That is what some people have trouble grasping. They confuse/intermix the two and then think that they need to find a "square" surface on the rifle. The best that you can hope for on any rifle surface that appears to be "square" is that it is parallel to the rifle bore. And even that is often questionable. And even if it were perfectly square, that does that guarantee alignment/centering of the scope mounts?

We do not need a bubble level to deal with #1. We do not rely on gravity for #1. As long as the gun is not totally jacked, #1 is corrected by simply rotating the scope in the rings. When the scope rotation is correct, lock down the scope rings.

Then move on to #2.

A bubble level is used to avoid gun cant (#2). The reticle is aligned with a plumb line, and then the bubble level is rotated on the scope tube until it indicates the middle/level. When the the bubble level rotation is correct, lock down the bubble level.

When we shoot, we hold so that the bubble indicates that the reticle is vertical.

Upvote 0

Nervoustrig,

Plus one for the easiest method I've learned to date to eliminate scope cant. I will employ this method this weekend, and find out how far off my scopes were! Thanks!

Plus one for the easiest method I've learned to date to eliminate scope cant. I will employ this method this weekend, and find out how far off my scopes were! Thanks!

Upvote 0

Thank you, sir, but credit goes to the gentleman who backed me up. Scott described this method to us on another forum and it’s so simple and elegant that I feel compelled to teach it to everyone.

Upvote 0

Great stuff guys, thanks for sharing!

I always use the string method that Tominco showed in one of his videos ... but was a bit at a loss with rifle cant.

I always use the string method that Tominco showed in one of his videos ... but was a bit at a loss with rifle cant.

Upvote 0

For my Sig Sauer scope with built in anticant, I put my scope mounts on a flat surface(used bubble leveler to make sure the table is flat), then I put the scope on the scope rings and activate the integrated anti cant in the scope and tighten the scope down to the scope rings. Finally when I put the scope rings and scope on the gun it doesn't matter if I have cant error on the gun  because it is already leveled with a flat surface. Sig Sauer claims it's Anticant is 3-5 times more accurate than standard bubble levelers.

because it is already leveled with a flat surface. Sig Sauer claims it's Anticant is 3-5 times more accurate than standard bubble levelers.

Anyways I'll be making a scope review soon .

.

Tinging/pinging 8 inch steel @150 yards with this method . Have not been able to see groups but the black specs at that distance indicates center hits within 4 inches.

. Have not been able to see groups but the black specs at that distance indicates center hits within 4 inches.

Anyways I'll be making a scope review soon

Tinging/pinging 8 inch steel @150 yards with this method

Upvote 0

I use a Tipton gun vice and a couple of levels too initially set up the Impact. My Nightforce unimount has a level as well, so after mounting the scope it's about as level as it can be to start the process. From there the hanging string works well, although I also use a particular door edge which has proved to be perfectly vertical.

Upvote 0

FukoChan and Quoddy, just FYI both of those methods are subject to having scope cant error for any of the various reasons cited above. If everything is machined very true and the scope mount is perfectly centered above the rail and the barrel has no lateral bias...the result will be good, as it seems to be in these cases. I just want to point out it may not be true on the next rifle or the one after that and it can be very frustrating to find the culprit if you have supreme confidence in how the scope was installed and leveled.

Upvote 0

Easiest way is to slightly loosen the mount schrews, look through the scope from a bit distance, and try to see the bottom crosshair in senter of the barrel. Adjust, and tighten the schrews. It is surprislingly effective.

Upvote 0

Here is what I use with my HW springers that have a "flat top barrel pivot block" and it works OK for me.

* Focus on a hanging string at 18 yards and loosening the top strap screws I use a tested torpedo level sitting on the barrel pivot block and the gun is leveled on a "high tech gun rest" (cardboard box with a couple vees cut in the sides)...........

After verifying that the "bubble" is still centered and the reticle aligns perfectly with the string I carefully tighten the mount top strap ring screws alternately from left to right in an "X pattern" using a couple in/lbs of torque at a pass till I get an even torque on all screws. The scope mount the final top strap torque is no more than 15 in/lbs for the UTG mounts per these specs.............

A while back I started using a UTG MNT-DTW145 universal dovetail to Picatinny adapter with a set of high inexpensive Weaver QuadLock rings and found that top strap torque as low as 10 in/lbs will firmly hold my 5-15x50 Hawke Panorama scope............

* Focus on a hanging string at 18 yards and loosening the top strap screws I use a tested torpedo level sitting on the barrel pivot block and the gun is leveled on a "high tech gun rest" (cardboard box with a couple vees cut in the sides)...........

After verifying that the "bubble" is still centered and the reticle aligns perfectly with the string I carefully tighten the mount top strap ring screws alternately from left to right in an "X pattern" using a couple in/lbs of torque at a pass till I get an even torque on all screws. The scope mount the final top strap torque is no more than 15 in/lbs for the UTG mounts per these specs.............

A while back I started using a UTG MNT-DTW145 universal dovetail to Picatinny adapter with a set of high inexpensive Weaver QuadLock rings and found that top strap torque as low as 10 in/lbs will firmly hold my 5-15x50 Hawke Panorama scope............

Upvote 0