When they first came out, I purchased three RX Targets from David Bitowski for my indoor range. My friends, business guests, and I have likely shot +100,000 projectiles using them. A couple of years ago, I did replace the original paddles with 1/4" paddles and they fared much better.

The RX Targets have been one of the best airgun related equipment purchases I have ever made. And David is a terrific guy, though I am concerned that something may be wrong, as totally unlike him, I have e-mailed him and attempted to call him on several occasions over the last few months with no response. I was attempting to reach him to buy a new face plate with smaller diameter holes for one of my targets, plus to see if I could get him to make replacement paddles for me that would be 3/8" to 1/2" longer.

As you can see in the accompanying photos, I had the face plates produced with different size holes in them. The smallest of them are only 3/8" and 7/64". Utilizing such small holes enhances the fun of shooting pcps at such close range, and they are great for validating that the rifle is perfectly sighted in and that the groups are consistently tight. However, a resulting issue of having such small holes is that one can't clearly see the targets go down, so I was using black spring clips with orange target dots on the clip handles, and while this system worked well, projectiles would knock them off with some frequency and they always required maintenance.

The second issue is, that while shooting super accurate pcps at the close indoor range (18 yards) and shooting through these small holes, particularly with +45 FPE rifles shooting slugs, they tend to "punch" and after tens of thousands of shots will punch through even the 1/4" paddles.

So after considerable thought, and having no success in reaching Dave recently, I addressed both problems this weekend on my own.

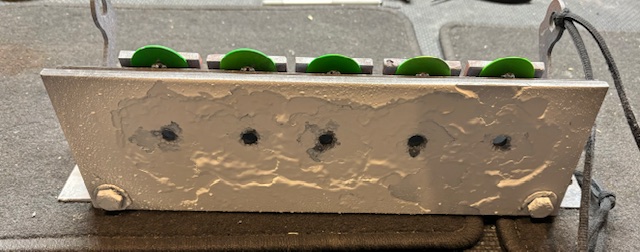

Five of the fifteen paddles had significant "punch" depressions. I ground off of the uneven surfaces and bored the slug depressions out to 3/8", and inserted a 3/8" machine screw to fill the hole, using loctite on the nut, though I am guessing the projectile impacts will freeze the nut in place anyway. By inserting the machine screw and protruding the length of the nut, it should give considerably more surface to absorb the impacts than did even the original design.

I then bored a 3/16" hole at the top and mounted a painted fender washer to give a visual marker to confirm the target actually drops at the shot.

One reassembled, I tested using my Air Arms S510 .177 shooting the Benjamin 10.5 Gr Match pellets at around 800 FPS, to be certain I hadn't made them too heavy with the additional weight of the 3/8" machine screw and nut attached. They all went down perfectly and it was really easy to confirm the hit with the bright green washers showing above the targets.

Everything is now ready for another few years of trouble free shooting!

.

The RX Targets have been one of the best airgun related equipment purchases I have ever made. And David is a terrific guy, though I am concerned that something may be wrong, as totally unlike him, I have e-mailed him and attempted to call him on several occasions over the last few months with no response. I was attempting to reach him to buy a new face plate with smaller diameter holes for one of my targets, plus to see if I could get him to make replacement paddles for me that would be 3/8" to 1/2" longer.

As you can see in the accompanying photos, I had the face plates produced with different size holes in them. The smallest of them are only 3/8" and 7/64". Utilizing such small holes enhances the fun of shooting pcps at such close range, and they are great for validating that the rifle is perfectly sighted in and that the groups are consistently tight. However, a resulting issue of having such small holes is that one can't clearly see the targets go down, so I was using black spring clips with orange target dots on the clip handles, and while this system worked well, projectiles would knock them off with some frequency and they always required maintenance.

The second issue is, that while shooting super accurate pcps at the close indoor range (18 yards) and shooting through these small holes, particularly with +45 FPE rifles shooting slugs, they tend to "punch" and after tens of thousands of shots will punch through even the 1/4" paddles.

So after considerable thought, and having no success in reaching Dave recently, I addressed both problems this weekend on my own.

Five of the fifteen paddles had significant "punch" depressions. I ground off of the uneven surfaces and bored the slug depressions out to 3/8", and inserted a 3/8" machine screw to fill the hole, using loctite on the nut, though I am guessing the projectile impacts will freeze the nut in place anyway. By inserting the machine screw and protruding the length of the nut, it should give considerably more surface to absorb the impacts than did even the original design.

I then bored a 3/16" hole at the top and mounted a painted fender washer to give a visual marker to confirm the target actually drops at the shot.

One reassembled, I tested using my Air Arms S510 .177 shooting the Benjamin 10.5 Gr Match pellets at around 800 FPS, to be certain I hadn't made them too heavy with the additional weight of the 3/8" machine screw and nut attached. They all went down perfectly and it was really easy to confirm the hit with the bright green washers showing above the targets.

Everything is now ready for another few years of trouble free shooting!

.