I have been very happy with my Altaros booster, but it's still a slow fill process. I have been wanting a quicker fill and at the same time have been considering the best way to cool a Yong Heng.

I've spent the last week drooling over the $3K compressors, but it wouldn't be a simple hookup for me as the house I am currently renting doesn't appear to have anything that will support high Amps without additional wiring. On top of that I just am having trouble putting out that amount on something that squishes air - i'll get there in time, maybe.

This got me thinking about the venerable Yong Heng compressor. The little bastard of the litter that everyone has gone through at least one of here. How can I cool the Yong Heng without pounds of ice, gallons of water and constantly watching that temp gauge hit 60*C and know you cylinder rings are dying a horrible death.

Wait - I forgot to mention the water pump they give you. Seriously - the one in the pump I just got literally mesasured 2"x2"x3" and the water fountain at school puts out more water.

Genius idea - why not run water straight from the tap and let it flow into a drain. Good golly, duh?!?!?

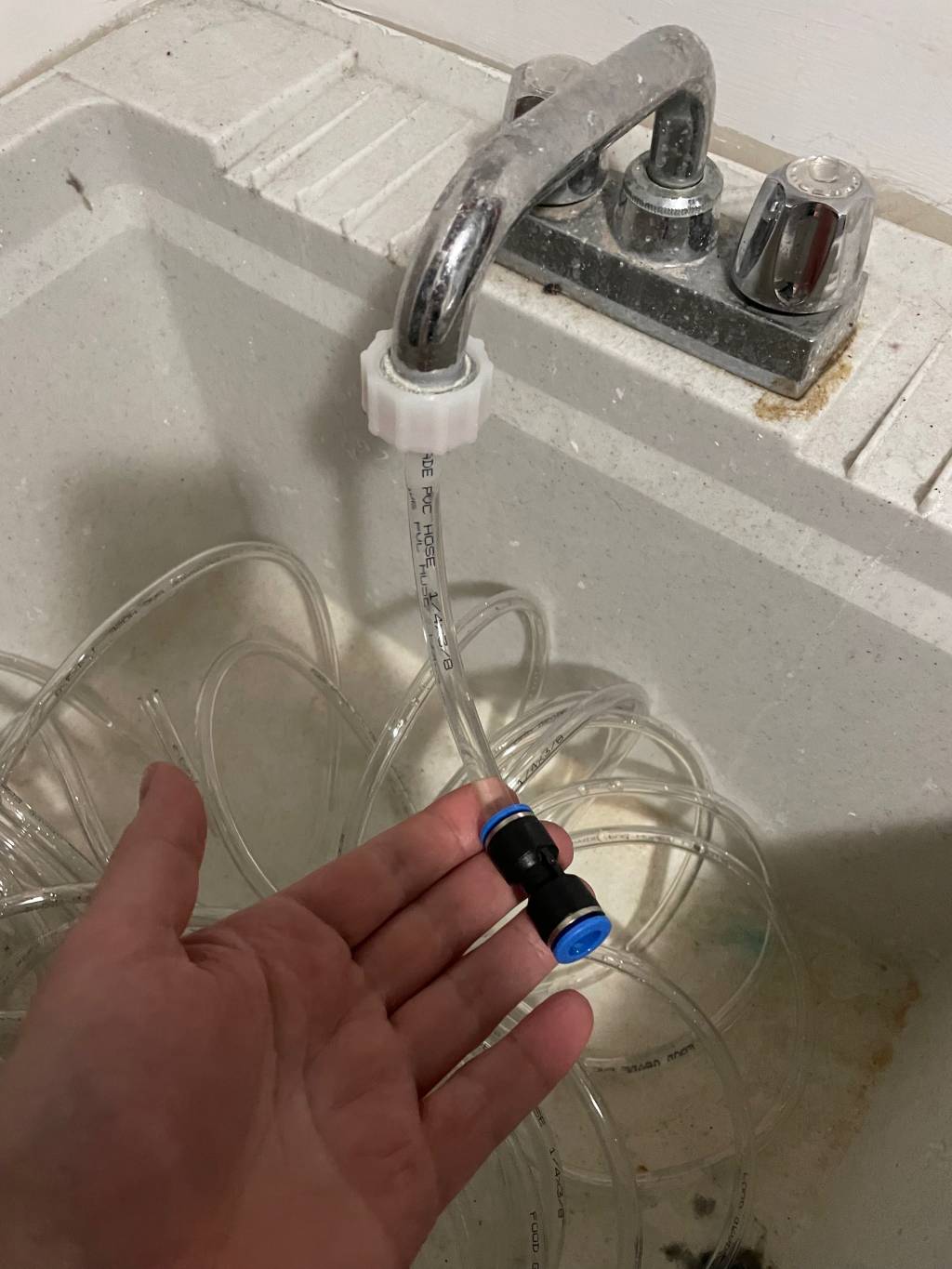

Got an adapter for a 3/8" OD tube to the basin sink in the basement. Attached a splitter so I don't have to keep tubing constantly attached.

Did the same on the compressor end so I don't need to keep long tubes attached.

Now you can run constant fresh water at a very fast rate depending on the faucet being turned on.

I filled my 9L tank from around 230 bar to 300 bar in around 10 minutes watching the temp gauge the whole time. Never went above 38.1*C. OH YEAH!!

I've spent the last week drooling over the $3K compressors, but it wouldn't be a simple hookup for me as the house I am currently renting doesn't appear to have anything that will support high Amps without additional wiring. On top of that I just am having trouble putting out that amount on something that squishes air - i'll get there in time, maybe.

This got me thinking about the venerable Yong Heng compressor. The little bastard of the litter that everyone has gone through at least one of here. How can I cool the Yong Heng without pounds of ice, gallons of water and constantly watching that temp gauge hit 60*C and know you cylinder rings are dying a horrible death.

Wait - I forgot to mention the water pump they give you. Seriously - the one in the pump I just got literally mesasured 2"x2"x3" and the water fountain at school puts out more water.

Genius idea - why not run water straight from the tap and let it flow into a drain. Good golly, duh?!?!?

Got an adapter for a 3/8" OD tube to the basin sink in the basement. Attached a splitter so I don't have to keep tubing constantly attached.

Did the same on the compressor end so I don't need to keep long tubes attached.

Now you can run constant fresh water at a very fast rate depending on the faucet being turned on.

I filled my 9L tank from around 230 bar to 300 bar in around 10 minutes watching the temp gauge the whole time. Never went above 38.1*C. OH YEAH!!