Alright you two (BigTinBoat, ClarkT),

Here's what I fixed and changed since my last post:

- The height of the base tray so, that its top plane just barely passes the center of the barrel as was suggested by BigTin.

- A modular trough system for calibers up to 7,62 mm, including the 7,62 caliber respectively. The .177 / 4,5mm, .22 / 5,5mm and the .25 / 6,35 mm calibers have their own, individual troughs now, which can be replaced for switching barrels or otherwise calibers of the gun at will

You could probably or rather most likely also fit a .45 ACP / .45 LC projectile into the base trough of the tray; that's of course, if the RTI company even makes a .45 cal. barrel for the Prophet PCP.

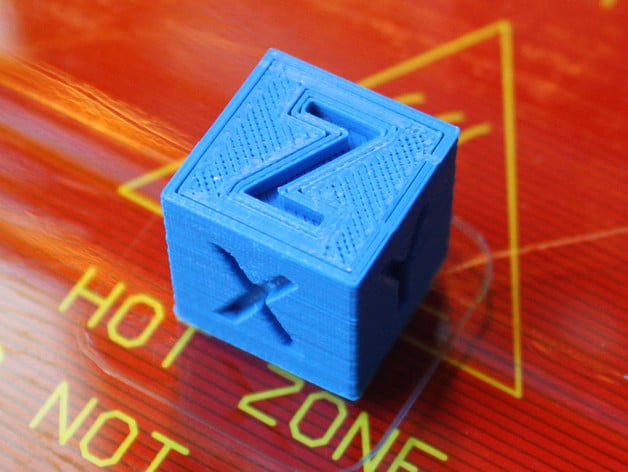

So, here are the images:

... and of course the .STL files:

View attachment RTI_Prophet_Trays_STLfiles.1625248863.zip

And that's pretty much it, I hope the prints are going to turn out well and that all of the dimensions are going to check out. I'd also like to see the prints when you're done printing and if the need be, sandpapering or otherwise perfecting them out.

Oh and one more thing... If you're ever going to shoot .30 cal and of course if you'd like to, you can give these pellets, that I've designed a go. You're just going to have to print them first, haha. If I'd have a printer and a .30 cal PCP or a springer (i.e. Hatsan 130S/ 135 in 7,62 mm), I'd do it myself, but since I don't have any of these two things, I must rely on others for results. I'm just really curious about what their performance is going to be; that was basically the only driving force behind the reason why I made these in the first place.

Link to the thread: https://www.airgunnation.com/topic/i-designed-a-3d-model-of-a-30-caliber-pellet-a-tester-needed/?referrer=1

So once again, I'd be thankful for the images of the prints and naturally I really hope those will turn out alright for you.

Have a good one,

- Triglav

I like it a lot! I’ll post up some pics when I can.

Upvote 0