The cocking arm was pinned onto the barrel, and secured with a new e-clip.

I lubed the top hat and inserted that inside the piston, then lubed the original spring with Maccari "black tar". Man, that stuff is messy.

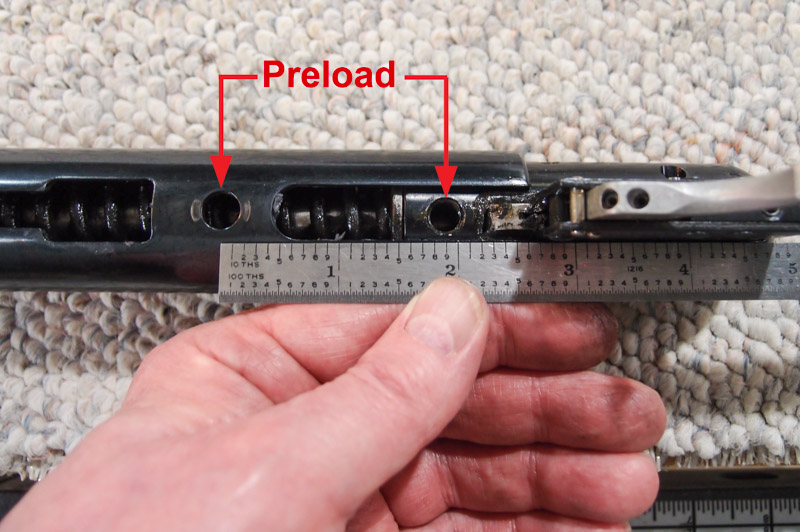

The spring and guide were inserted, and it was time to put on the trigger assembly to hold it all in. I noted that there was 1.9" of preload on my old original spring. It definitely requires a spring compressor to get it back together. In the photo below, the spring is butted against the trigger assembly and I still have to align the two holes at the arrows to be able to attach the threaded stud.

In the spring compressor and tightening trigger assembly screws to hold everything together...

And done.

I lubed the top hat and inserted that inside the piston, then lubed the original spring with Maccari "black tar". Man, that stuff is messy.

The spring and guide were inserted, and it was time to put on the trigger assembly to hold it all in. I noted that there was 1.9" of preload on my old original spring. It definitely requires a spring compressor to get it back together. In the photo below, the spring is butted against the trigger assembly and I still have to align the two holes at the arrows to be able to attach the threaded stud.

In the spring compressor and tightening trigger assembly screws to hold everything together...

And done.

Upvote 0