I fumbled my Carm magazine when loading it and it fell on a hardwood floor. It jarred something internally and now the magazine has no tension and the next pellet stopper doesn't work. It just spins back loosely. If I could get it apart I might be able to reattach the spring but I can't see how it comes apart. Works beautifully unless you ham fist it onto a hardwood floor. I prefer not to use the ball peen hammer opening method.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Repair Carm magazine for daystate

- Thread starter Jim81

- Start date

Never needed to take any of mine apart but there must probably be an Allen screw holding them together?

Probably your spring tensioner popped out of its set anchor hole just needs to be put back and wound a little before reassembly.

Probably your spring tensioner popped out of its set anchor hole just needs to be put back and wound a little before reassembly.

Upvote 0

I’ve had this exact thing happen last week to one of mine too.

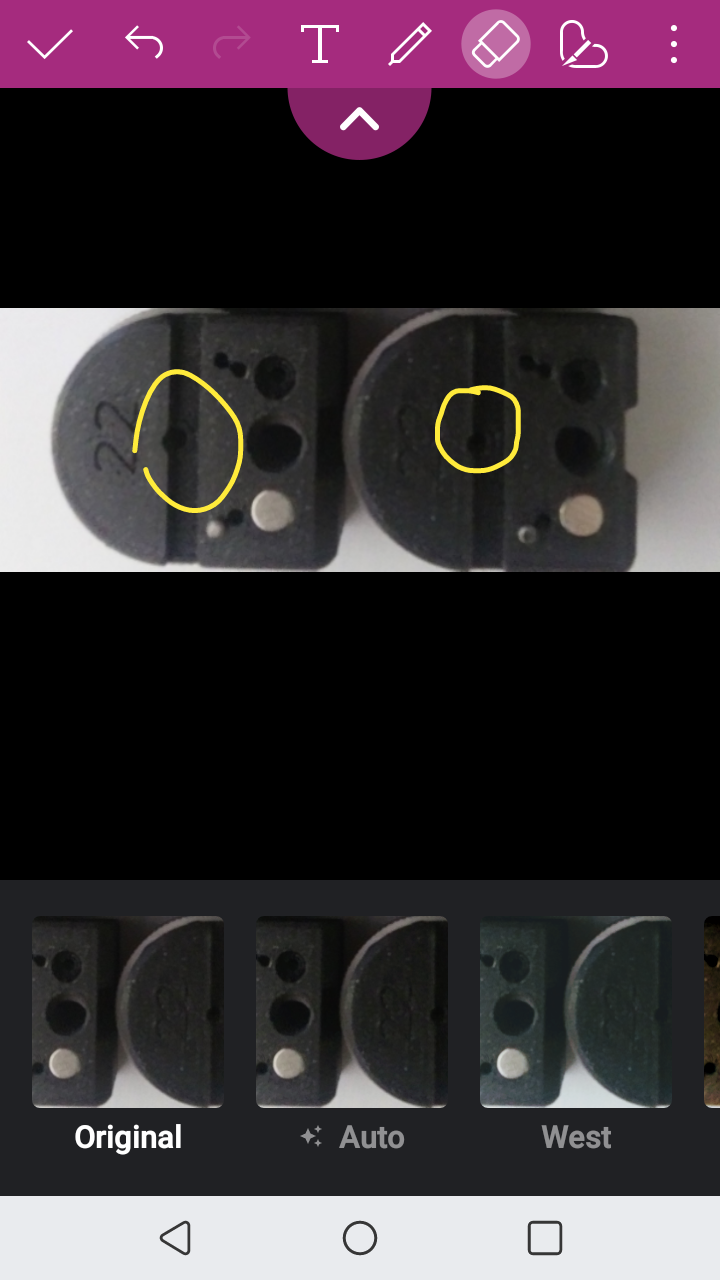

The little flat plastic tab (the ‘stopper’) that prevents the mag from unwinding (by a pellet which blocks the opening for the tab to pass through) is broken off due to the violent impact of the pellet slamming against it when coming to an abrupt stop due to a sudden decelleration.

This stopper piece is really the only vulnerable part of the mag, as it is very small and flat and as such has very little attachment to the mag wall. But if you still have it, it is easily superglued back in place, as the PETG material is very easy to glue with CA. (Superglue)

Opening the mag is simply by unscrewing the central screw, and then lifting the flat front lid from the 2 small metal bars on the bigger black part (the ‘rear’ part of the mag house). Now glue the tab back in place, or if lost use any other small piece to device a stopper from. It must be so lean that the rotating part of the mag is able to turn freely without any resistance. (There is a trench in the rotating mag part through which the stopper moves). To reinforce the attachment you could put a very small(!) dab of CA on the base of it and cover that with baking soda to form a fillet. (An old model building trick). Then use a small file to shape the fillet so the rotor is not impeded in its movement.

Alternatively you could drill a small hole in the lid at the point where the plastic tab would come in contact with the pellet and put a small metal bar (like a small cut off piece of a nail) through and fix that in place with CA super glue.

When reassembling give the spring one full rotation for pre tensioning (2r evs is to much, you will not be able to fully load the mag anymore). This process is a little fiddly, as you have to partly assemble the rotor on the house (with the spring in between) rotate the rotor and at one point you have to lift the rotor up to pass over the ‘magazine empty’ end stop. (Takes a few tries, what helps is to put a small dowel against the central pole so the spring will not unwind off of it.)

When all is done the mag works as good as before! Good luck!

The little flat plastic tab (the ‘stopper’) that prevents the mag from unwinding (by a pellet which blocks the opening for the tab to pass through) is broken off due to the violent impact of the pellet slamming against it when coming to an abrupt stop due to a sudden decelleration.

This stopper piece is really the only vulnerable part of the mag, as it is very small and flat and as such has very little attachment to the mag wall. But if you still have it, it is easily superglued back in place, as the PETG material is very easy to glue with CA. (Superglue)

Opening the mag is simply by unscrewing the central screw, and then lifting the flat front lid from the 2 small metal bars on the bigger black part (the ‘rear’ part of the mag house). Now glue the tab back in place, or if lost use any other small piece to device a stopper from. It must be so lean that the rotating part of the mag is able to turn freely without any resistance. (There is a trench in the rotating mag part through which the stopper moves). To reinforce the attachment you could put a very small(!) dab of CA on the base of it and cover that with baking soda to form a fillet. (An old model building trick). Then use a small file to shape the fillet so the rotor is not impeded in its movement.

Alternatively you could drill a small hole in the lid at the point where the plastic tab would come in contact with the pellet and put a small metal bar (like a small cut off piece of a nail) through and fix that in place with CA super glue.

When reassembling give the spring one full rotation for pre tensioning (2r evs is to much, you will not be able to fully load the mag anymore). This process is a little fiddly, as you have to partly assemble the rotor on the house (with the spring in between) rotate the rotor and at one point you have to lift the rotor up to pass over the ‘magazine empty’ end stop. (Takes a few tries, what helps is to put a small dowel against the central pole so the spring will not unwind off of it.)

When all is done the mag works as good as before! Good luck!

Upvote 0

Great post. I have two out of 3 carms with the same problem. I foolishly threw the two small broken stopper tabs away. I am thinking of a work around. Perhaps a small flathead screw through the back of the mag? I am going to try something. I will post pics if it works.I’ve had this exact thing happen last week to one of mine too.

The little flat plastic tab (the ‘stopper’) that prevents the mag from unwinding (by a pellet which blocks the opening for the tab to pass through) is broken off due to the violent impact of the pellet slamming against it when coming to an abrupt stop due to a sudden decelleration.

This stopper piece is really the only vulnerable part of the mag, as it is very small and flat and as such has very little attachment to the mag wall. But if you still have it, it is easily superglued back in place, as the PETG material is very easy to glue with CA. (Superglue)

Opening the mag is simply by unscrewing the central screw, and then lifting the flat front lid from the 2 small metal bars on the bigger black part (the ‘rear’ part of the mag house). Now glue the tab back in place, or if lost use any other small piece to device a stopper from. It must be so lean that the rotating part of the mag is able to turn freely without any resistance. (There is a trench in the rotating mag part through which the stopper moves). To reinforce the attachment you could put a very small(!) dab of CA on the base of it and cover that with baking soda to form a fillet. (An old model building trick). Then use a small file to shape the fillet so the rotor is not impeded in its movement.

Alternatively you could drill a small hole in the lid at the point where the plastic tab would come in contact with the pellet and put a small metal bar (like a small cut off piece of a nail) through and fix that in place with CA super glue.

When reassembling give the spring one full rotation for pre tensioning (2r evs is to much, you will not be able to fully load the mag anymore). This process is a little fiddly, as you have to partly assemble the rotor on the house (with the spring in between) rotate the rotor and at one point you have to lift the rotor up to pass over the ‘magazine empty’ end stop. (Takes a few tries, what helps is to put a small dowel against the central pole so the spring will not unwind off of it.)

When all is done the mag works as good as before! Good luck!

Upvote 0

Let Carm Mags know as he can improve his productionGreat post. I have two out of 3 carms with the same problem. I foolishly threw the two small broken stopper tabs away. I am thinking of a work around. Perhaps a small flathead screw through the back of the mag? I am going to try something. I will post pics if it works.

Upvote 0