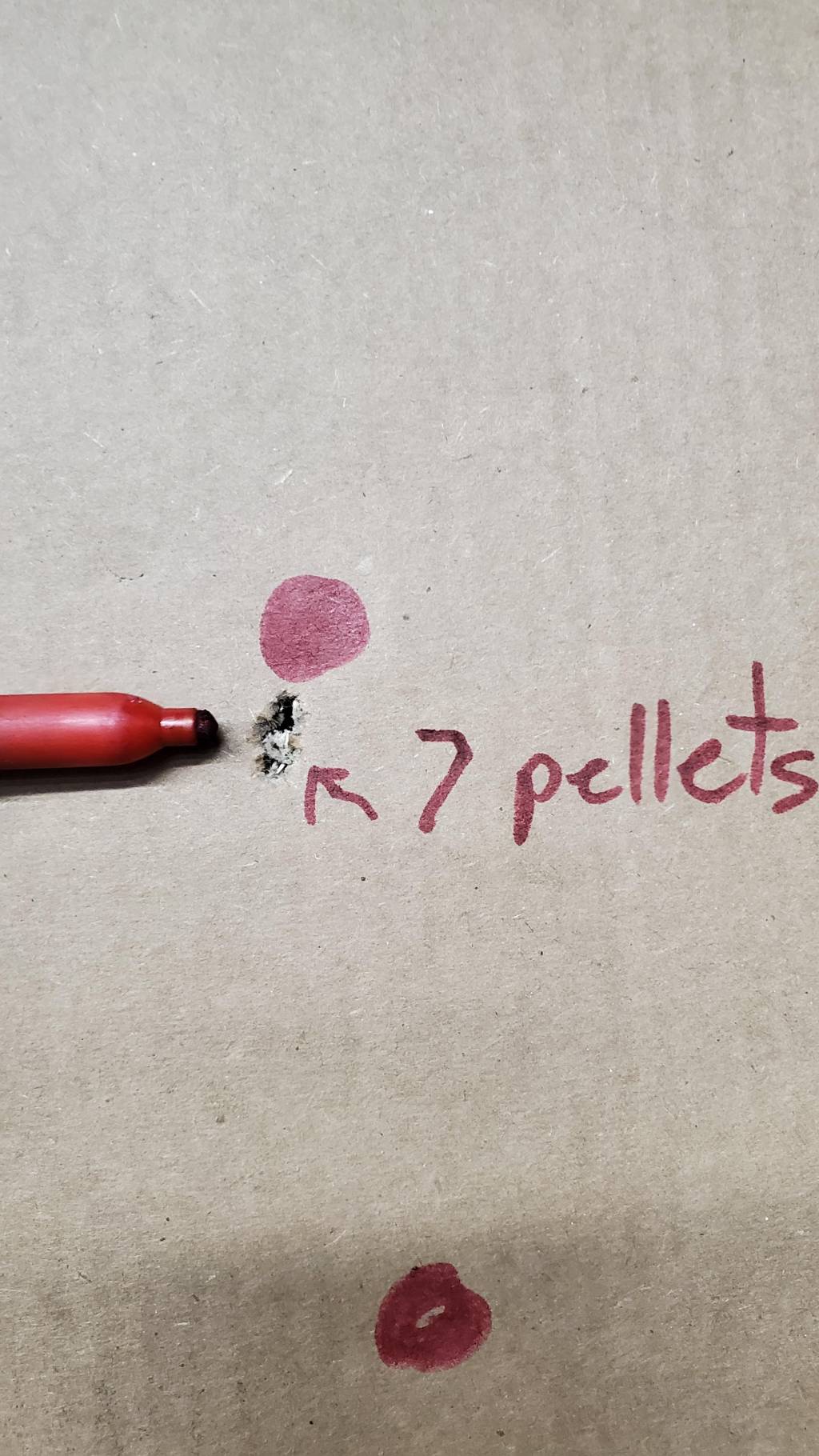

My o rings were damaged from last time I took the barrel out. So I had to debur the grub screw holes and transfer port. The grub screw holes I had to do by hand with cratex, and took about a half hour straight polishing. The rest went smooth thankfully, and when I reseated the barrel, the o rings felt great going in, no snags or rips I could feel and now the gun is back to firing pencil eraser size groups. The target in the pic is 15 yards, 7 pellets jsb 18.13

In the picture showing the slug on the jag there is a right angle metal scribe. It's made to scribe layout lines in tough to reach spots. Now I'm ver new to airguns, but I'm not new to my trade, an old timer taught me this is the best tool possible for removing O rings. It allows you to stab into the old o ring and lift it out so it can be hooked with another tool. It's a bad idea to try and get around the o ring because it's easy to damage the walls of the o ring groove. Just a little tip an old man taught me, I hope it helps.

In the picture showing the slug on the jag there is a right angle metal scribe. It's made to scribe layout lines in tough to reach spots. Now I'm ver new to airguns, but I'm not new to my trade, an old timer taught me this is the best tool possible for removing O rings. It allows you to stab into the old o ring and lift it out so it can be hooked with another tool. It's a bad idea to try and get around the o ring because it's easy to damage the walls of the o ring groove. Just a little tip an old man taught me, I hope it helps.