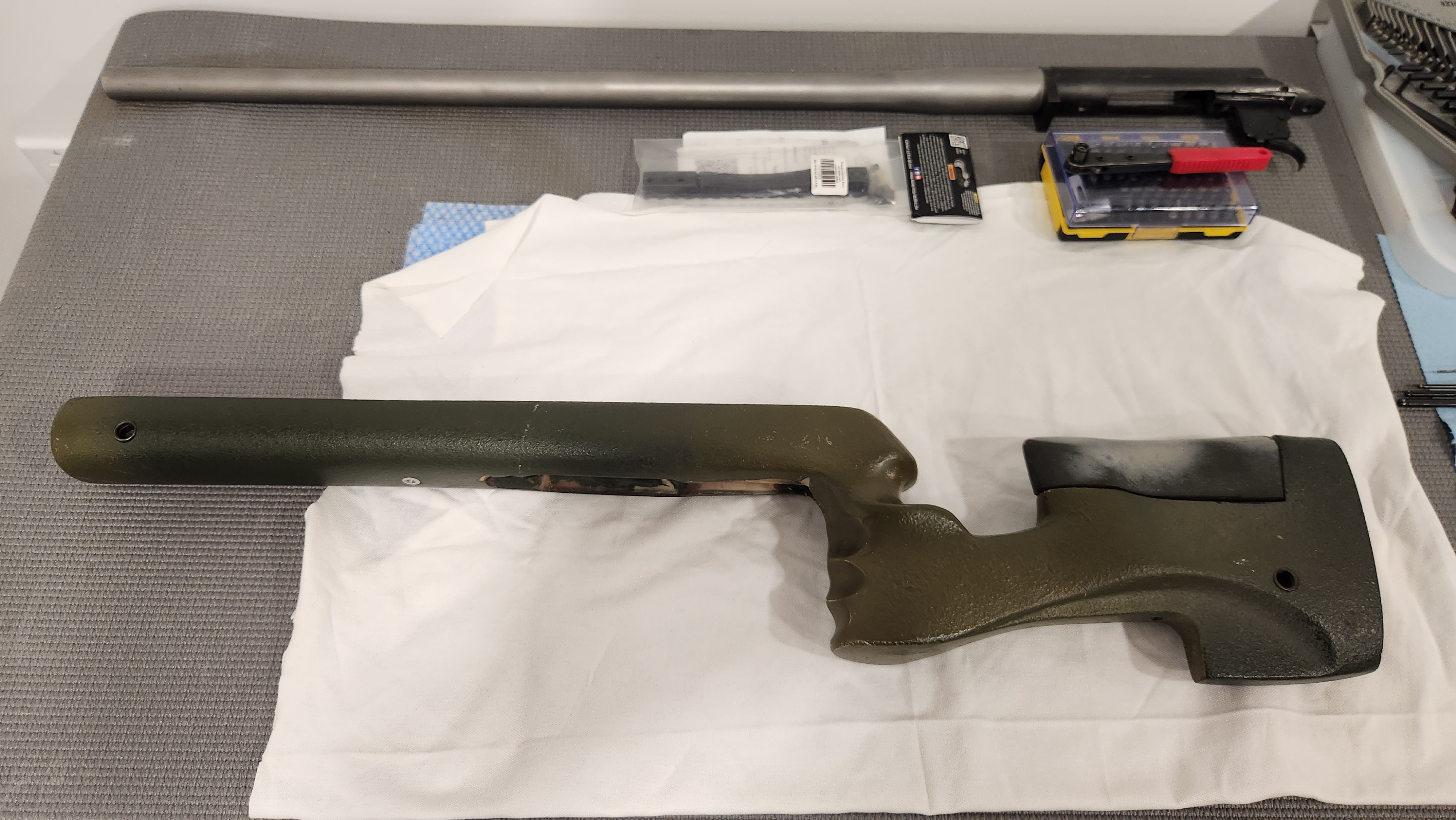

This f-class project got to my hands last week from a very older fella.

The metal parts look and feels promising, but the plastic/composite stock is killing me. I know getting some chassis would be a better option, but I don't want to spend that money on this thing that will be seeing sunlight ones or twice a year.

I would like to remove the old paint layers and refresh the look a little bit more modern and pleasing, maybe air dry ceracoat or hydrodip...

The first problem I am seeing that sanding this part may take a lifetime. What else?

Anybody have an experience to share?

The metal parts look and feels promising, but the plastic/composite stock is killing me. I know getting some chassis would be a better option, but I don't want to spend that money on this thing that will be seeing sunlight ones or twice a year.

I would like to remove the old paint layers and refresh the look a little bit more modern and pleasing, maybe air dry ceracoat or hydrodip...

The first problem I am seeing that sanding this part may take a lifetime. What else?

Anybody have an experience to share?