You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Tuning Re cutting the crown on an air rifle barrel.

- Thread starter Corvid_hunter

- Start date

Here you go:I center the bore up in my lathe then cut an 11 degree crown. I would do my pcp barrel the same way. in a production setting that takes too much time. Most production shops would use a crowning tool with an pilot that fits the bore. In theory it will cut a square crown to the bore and has no setup time. I am surprised FX or whoever makes the liners for them dont use a cutting tool with a pilot. If the bores dimensions are not consistent liner to liner then a cutter and pilot doesnt work as well.

Tuning - FX Superior liners - uneven crown

Howdy! Please just take a look. This is the same liner rotated by about 180*: How can they shoot pretty straight? Pretty much every liner which I examined has that problem.

Upvote 0

The cutting tool with a pilot can - and most likely will - leave scratch marks inside rifling. Take a high mag jewellery lupe and look yourself.

Upvote 0

Are you asking me? No I have not recrowned any pcp liners. I have threaded a couple of my pcp barrels like a bsa S10 and re cut the crown during the process. My FX Crown is very accurate and I have not inspected the crown and have no reason to or to re cut since its extremely accurate.Have you recrowned your liners?

Upvote 0

I wouldnt use a piloted cutter on any of my own builds. Many people do use piloted crowning tools with great success. Have you ever seen what the inside of a barrel looks like after being button rifled? A cutter for crowning a barrel using a pilot if used correctly doesnt come close to what the bore looks like after being button rifled.The cutting tool with a pilot can - and most likely will - leave scratch marks inside rifling. Take a high mag jewellery lupe and look yourself.

Upvote 0

I made a bunch of precise live-pilot bushings for my crown chamfering tools that I run with a floating tool holder, but when I actually turn my crowns in the traditional sense, I found that I get minimal burring and exert less material stress by turning in reverse with super sharp carbide upside down in the tool holder. The carbide "shaves" the rifling a lot smoother than it would normally by "chipping" away at the bore material.

6 million ways to skin a cat though lol

6 million ways to skin a cat though lol

Upvote 0

I've seen some pretty poor crowns on PBs do well also. Must just be the balance of two wrongs making a right... Still, that's hard to do intentionally, so the most predictable outcome comes from cutting (or grinding) a fine, uniform crown. I face with a standard cutter, much as shown in the video, but then recess and crown with successive very-light cuts (0.0005" - 0.001") from inside to out with a solid carbide micro boring bar while running the lathe at high speed.Pellet guns must be more forgiving of their crowns. I’ve seen some ugly crowns shoot pretty well. Now on my slug barrels, my crowns are razor sharp. No chamfering or anything that risks absolute concentricity.

GsT

Upvote 0

lol. Looks like they cut the crown with their teeth. Hopefully the brass screw trick will help itLooks rough

Upvote 0

I have Re-Crowned all my barrels and liners.. as I get them.... It is one of the Most Important Part of the Barrel!!!

In the beginning I used to cut my 11° the traditional way, using a sharp carbide boring bar cutter.

Then finish it of with a brass polishing arbor...

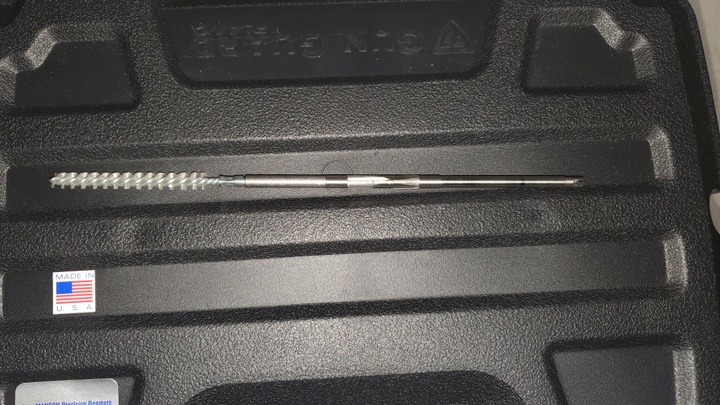

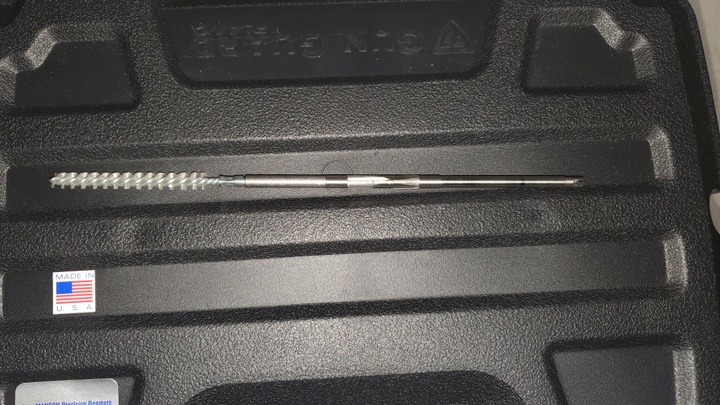

But Now I use a Mason Crown Cutter Setup.

This consists of a Pilot Rod that is Fixed in the Barrel(non-rotating), that also has an integrated swarf brush

The 11° Cutting Head. I use 3 serrated Carbide cutters to do the job!

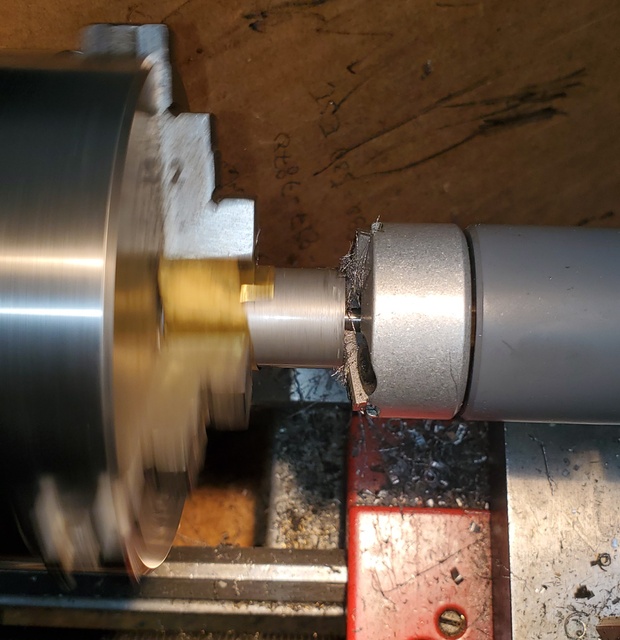

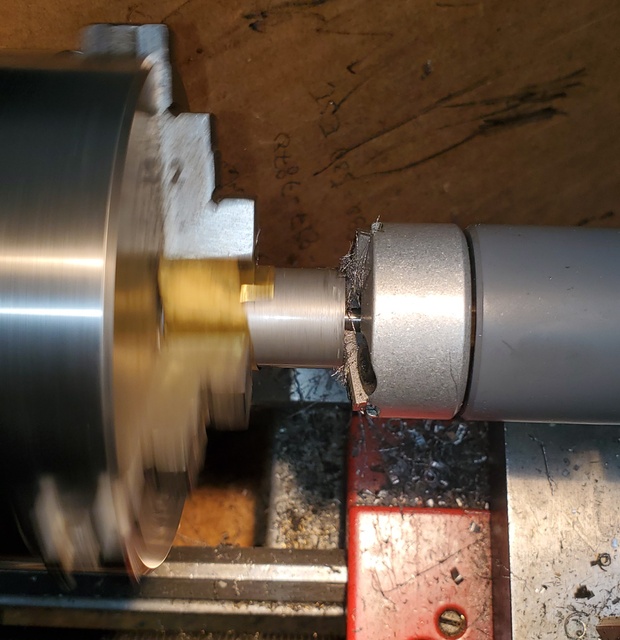

Here is the Mason Crown Cutter in action....

Notice the thin threads of swarf it produces.. This what it make the setup Unique!

This Crown it produces is precise with a Clean sharp Edge!.. No roll-over edge here..

The only thing left to do is a polishing to make the "Face" pretty!

I also use my Mason Crown Cutter on my FX liners....

I also turn down the liner at the crown area

This so it will pass through the Threaded Liner Lock.

So if you have access or have a friend with a decent lathe... Best to have it done Right!

Good Luck.......

In the beginning I used to cut my 11° the traditional way, using a sharp carbide boring bar cutter.

Then finish it of with a brass polishing arbor...

But Now I use a Mason Crown Cutter Setup.

This consists of a Pilot Rod that is Fixed in the Barrel(non-rotating), that also has an integrated swarf brush

The 11° Cutting Head. I use 3 serrated Carbide cutters to do the job!

Here is the Mason Crown Cutter in action....

Notice the thin threads of swarf it produces.. This what it make the setup Unique!

This Crown it produces is precise with a Clean sharp Edge!.. No roll-over edge here..

The only thing left to do is a polishing to make the "Face" pretty!

I also use my Mason Crown Cutter on my FX liners....

I also turn down the liner at the crown area

This so it will pass through the Threaded Liner Lock.

So if you have access or have a friend with a decent lathe... Best to have it done Right!

Good Luck.......

Upvote 0

D

Deleted member 54174

Guest

Another thing, how is the pilot supposed to work correctly if your barrel or liner is choked.

Upvote 0

A plain pilot carries a moderate risk of damaging the lands. A floating pilot is pretty safe by comparison.I herd the pilots cause damage to the soft, airgun barrels?

Upvote 0

D

Deleted member 54174

Guest

Okay, how is this floating pilot going to work for a choked barrel. Is the pilot tapered.

Upvote 0

D

Deleted member 54174

Guest

I'm trying to wrap my pea brain around this, so the floating pilot only makes contact further in the barrel with the attached brush?

Upvote 0