I have just been reading the RAW airguns =low quality thread. Unanimously it was agreed that there has been no real loss of quality between old and new and there was strong agreement that although they are very good out of the box, there are things that can be done to make them so much better.

Here is a list of the things I have done to my RAW and rapids that not only improve consistency, efficiency, accuracy, smoother and quieter but also makes gun feel nicer to shoot. For context, I almost exclusively work on sub12fpe airguns so some of my modifications may not be appropriate for higher power.

Barrel, re-crown, polish, stepped transfer port from 4.75mm down to 2.8mm, form a small lead into breech for better pellet insertion.

Calibre specific sound moderator typical 0.5mm larger than pellet Dia.

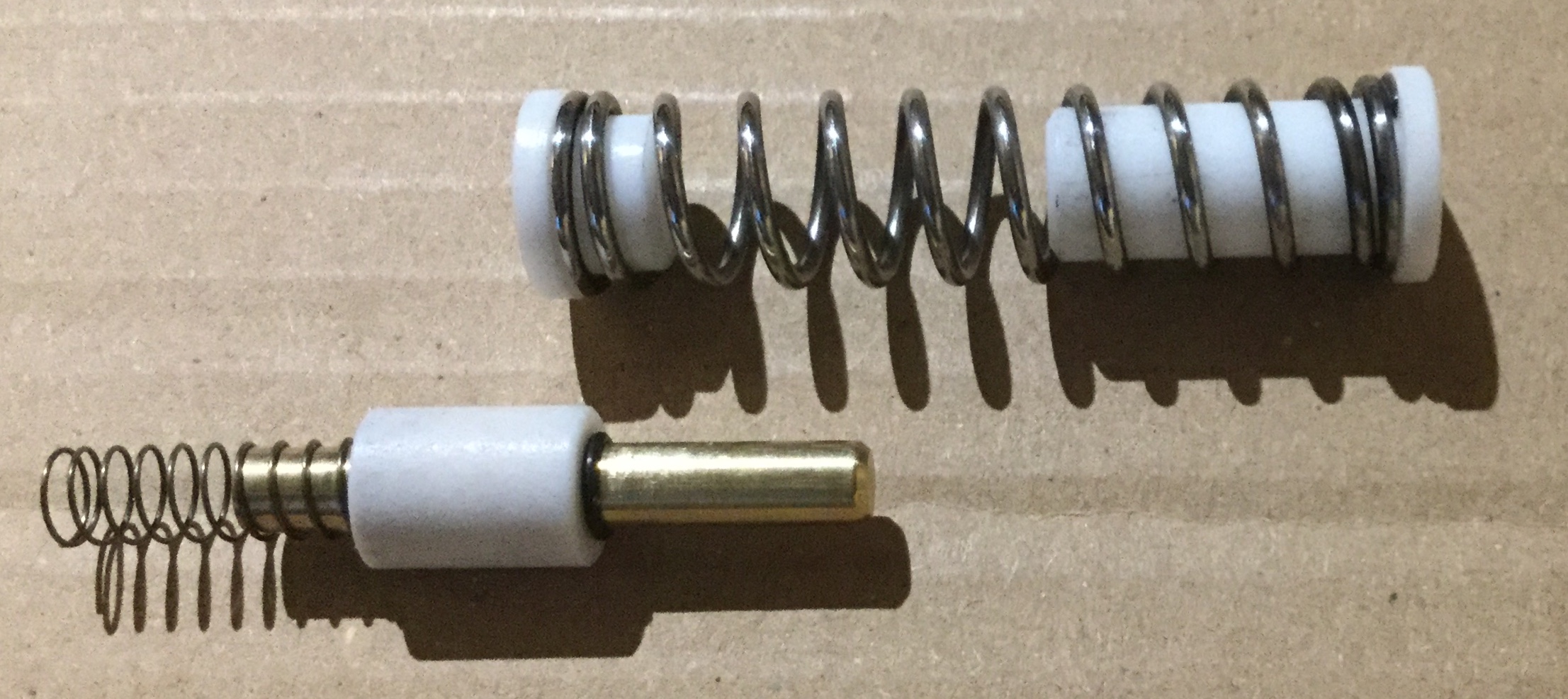

Lighter hammer, silent acetal tip to hammer pip, a PTFE hammer support sleeve to stabilise and centralise the hammer inside the block (reduces vibration noise)

Either an SSG device or a heavier inertia weight (in ptfe sleeve) to increase efficiency

Ground and polished hammer spring, ptfe spring guide to reduce friction and twang.

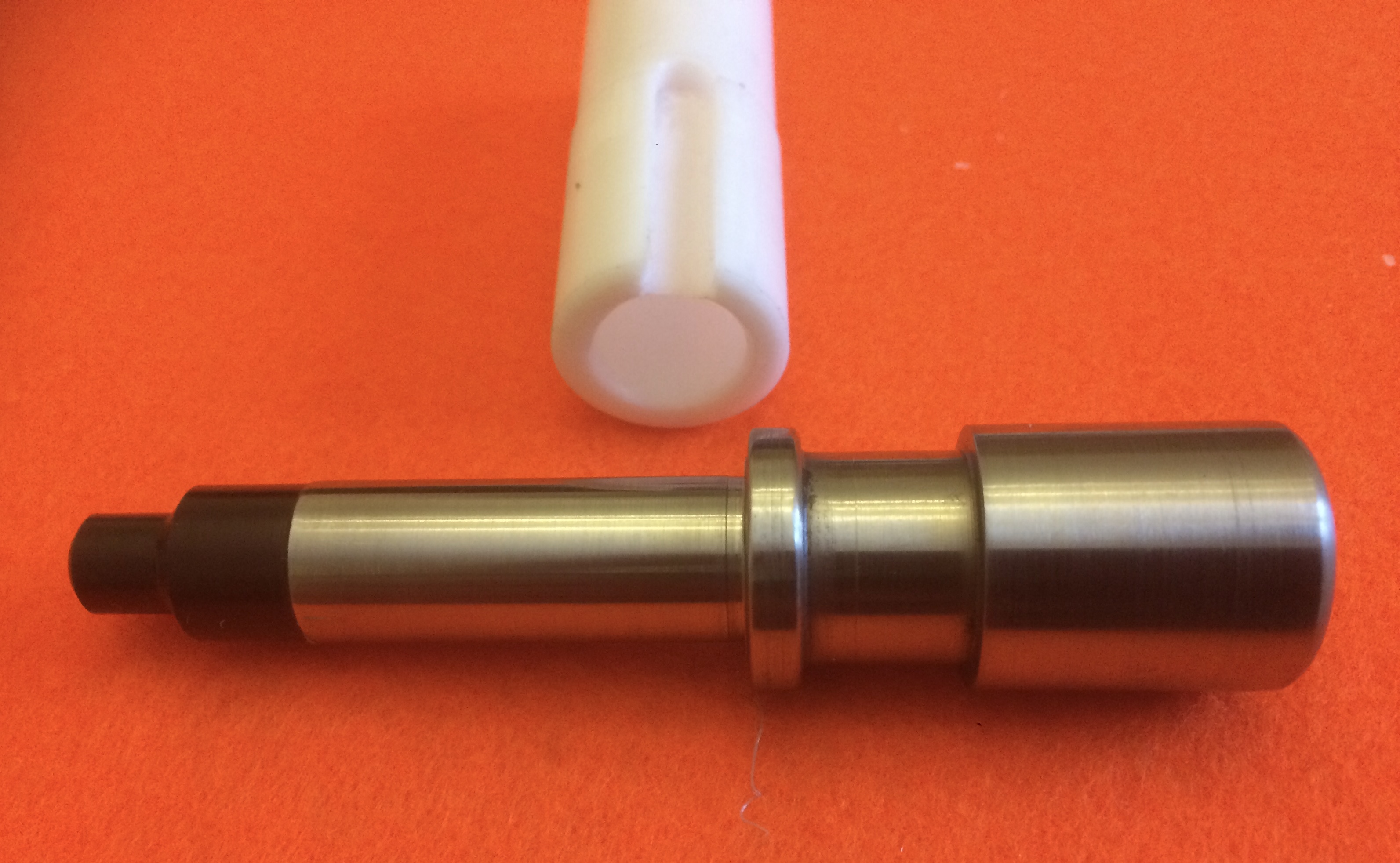

New valve with 5.5mm front port and 5mm top port, new lighter valve stem with stronger return spring

Replace reg pushpin disc and replace it with one that has a smaller hole (0.3mm) peek insert in end of reg core, new .8mm belville washers that I have de-burred on 800grt paper, instead of twin .5mm (these give a neater stack) together these give more consistently over a wider fill pressure.

On 1000x block only, Fill the reg plenum with acetal plug to reduce volume, this makes the reg quicker to respond to pressure drop.

Replace the probe with either a non retractable version for single loading only or a improved retractable type for use with magazine

Shim the cocking lever to reduce any slop.

Generally, I don’t need to tough the trigger but very occasionally I have polished the trigger sear and replaced trigger blade for aftermarket multi adjustable target type..

Obviously some of these modifications only have minimal gains but collectively they do make a huge difference. I am sure there are other improvements that I haven yet thought of but I’m always willing to learn from others

Bb

Here is a list of the things I have done to my RAW and rapids that not only improve consistency, efficiency, accuracy, smoother and quieter but also makes gun feel nicer to shoot. For context, I almost exclusively work on sub12fpe airguns so some of my modifications may not be appropriate for higher power.

Barrel, re-crown, polish, stepped transfer port from 4.75mm down to 2.8mm, form a small lead into breech for better pellet insertion.

Calibre specific sound moderator typical 0.5mm larger than pellet Dia.

Lighter hammer, silent acetal tip to hammer pip, a PTFE hammer support sleeve to stabilise and centralise the hammer inside the block (reduces vibration noise)

Either an SSG device or a heavier inertia weight (in ptfe sleeve) to increase efficiency

Ground and polished hammer spring, ptfe spring guide to reduce friction and twang.

New valve with 5.5mm front port and 5mm top port, new lighter valve stem with stronger return spring

Replace reg pushpin disc and replace it with one that has a smaller hole (0.3mm) peek insert in end of reg core, new .8mm belville washers that I have de-burred on 800grt paper, instead of twin .5mm (these give a neater stack) together these give more consistently over a wider fill pressure.

On 1000x block only, Fill the reg plenum with acetal plug to reduce volume, this makes the reg quicker to respond to pressure drop.

Replace the probe with either a non retractable version for single loading only or a improved retractable type for use with magazine

Shim the cocking lever to reduce any slop.

Generally, I don’t need to tough the trigger but very occasionally I have polished the trigger sear and replaced trigger blade for aftermarket multi adjustable target type..

Obviously some of these modifications only have minimal gains but collectively they do make a huge difference. I am sure there are other improvements that I haven yet thought of but I’m always willing to learn from others

Bb

Last edited: