Would amsoil PCK compressor oil be ok to use in my yong heng? It's a 30 to 40 weight and a flash point of 504 degrees

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

question for knifemaker about oil

- Thread starter Plasticfire

- Start date

Usually any oil is fine. Some even use car engine oil and it works fine for them. I tried hydraulic oil 46 like the manual recommended. I tired royal purple. I tired regular compressor oil for those shop compressor. All works fine. I can't tell a difference. All the oil really does is just lubricant the shaft. I dont think it matters which oil you go for. They all will work.

Upvote 0

Oil makes a big difference. Normal compressor is rated to 350 psi. After that point there become no cushion of oil due to pressure especially when pressures reach above 1000 psi. Yes it will work but will not work in the long haul. Better to use proper oil for the use intended for.

Upvote 0

Usually any oil is fine. Some even use car engine oil and it works fine for them. I tried hydraulic oil 46 like the manual recommended. I tired royal purple. I tired regular compressor oil for those shop compressor. All works fine. I can't tell a difference. All the oil really does is just lubricant the shaft. I dont think it matters which oil you go for. They all will work.

Nothing could be further from the truth. the issue is NOT the crank but rather the carbon build up on the upper part of the high piston and the reed valves. This caused accelerated wear on the rings and worse, back pressure due to the reed valves not being able to close completely. Results can lead to longer fill times, higher heat and in worse cases. crank cases or complete failure of the pistons top and undue pressure on the crank itself.

Proper oil in the #1 most important thing you can do for your compressor. Even more so than keeping the oil clean! And we all know how important that is!

Many of us use lesser quality built compressors than the Alkin, or other high quality compressors. Even Alkin says their compressors cannot withstand poor quality oil. How can we expect lesser units to live in such an environment when even the top products cannot.

My question is how many times must this simple fact be shown before people pay attention. It is a simple matter. Standard compressor oils for standard low pressure compressor, Non Mineral, ester base oils for HP compressors. Period!!!

Şekil 2-Compressor Unit W31 Series compressors are design and manufactured with intercooler serpentine located between 1st -2 nd Stage cylinders, and aftercooler located at the 3rd Stage outlet. There are water separators at the outlet of 2nd Stage intercooler and at outlet of 3rd Stage aftercooler. Water Separators are connected to auto drain valves that periodically drains the condensate water. The duration and frequency of opening of these drain valves are determined by the time relay located in the electric panel. (Please see Check section.) This time relay can be set for both functions. There is a Safety Valve at each stage to prevent an unwanted increase in pressure resulted from a problem in valves or any other parts. It must be periodically checked that, these safety valves are working properly and they keep their set pressure values. (Please see Maintenance Table.) W31 Series compressors are equipped with stainless valves at each stage that are designed to maintain the airflow without any loss of pressure. They are easy to maintain and replace. The maintenance of valves are especially important as they are the main parts in proper and problem-free working of compressors. Lubricants not approved by ALKIN can prevent valves from working properly due to the accumulation of carbon on springs and washers. Valves not working properly will cause an increase in working temperature and the deterioration of lubricant, thus in return, will further break down the valves. Max working pressure is 350 bar and, it is dangerous and strictly prohibited to set a value higher than 350 bar. ALKIN will not be held liable for any problems resulting from acting otherwise. Working temperature range of the compressor is –10/+50 ºC.

This is the very abrasive carbon deposit form improper oil. Notice the area where the reed valve rest. It can no longer seal. Yet the poster though it was looking good with no harm what so ever. Again, nothing could be further from the truth. It is pending doom for this poor unit! It will lead to failure period! (Note the coating on the synthetic piston ring. Might as well be sand paper). This is one of those cases where the saying "Here's your sign is appropriate.

Note, Y.H. NO LONGER Recommends # 46 due to the damage is caused their units. Hello! they now Recommend Mobil Rarus 827 which I use and is much more costly that any other I know of. I just switched to the Nuvair oil due to less older.

https://www.ebay.com/itm/MOBIL-827-Rarus-12oz-Oil-4500-PSI-Extreme-HIGH-Pressure-Yong-Heng-Air-Compressor/274608618484?ssPageName=STRK%3AMEBIDX%3AIT&_trksid=p2057872.m2749.l2649

Nuvair has the proper oils for no more than Royal Purple or Amsoil if you by 1 gal at a time. Why on earth would you risk otherwise?

https://www.nuvair.com/nuvair-751.html

Sorry for the rant, however, it irks me to see people that have no idea what they are talking about giving advice as if it were fact. Particularly when it can and will cause damage to others equipment or guns. GRRRRRRR!!!!

Knife

Upvote 0

Here is the oil Iam using in my Tuxing 2 cylinder compressor and works well.

https://filtertechs.com/shop/oil-media/compressor-oil/cl-581715-lq/

https://filtertechs.com/shop/oil-media/compressor-oil/cl-581715-lq/

Upvote 0

I also have used oil from Filtertechs.com in my compressors. This one is Secolube 500 which is the same as Anderol 750 that Alkin recommends for their compressors.

https://filtertechs.com/shop/oil-media/compressor-oil/cl-581815-lq/

+1 for Knifemaker. Your post is informative and shows why cheap oil is fool's gold. Good to know you also got on the Filtertechs bandwagon instead of $$$$$ Rarus 827. Yong Heng's manual went from recommending Ramin noodles to Baluga caviar in their oil recommendation extremes.

https://filtertechs.com/shop/oil-media/compressor-oil/cl-581815-lq/

+1 for Knifemaker. Your post is informative and shows why cheap oil is fool's gold. Good to know you also got on the Filtertechs bandwagon instead of $$$$$ Rarus 827. Yong Heng's manual went from recommending Ramin noodles to Baluga caviar in their oil recommendation extremes.

Upvote 0

LMAO! good one!

I forgot to add a very important part, why we don't use motor oil.

A motor vehicles oil is designed to float the particulate in the oil to be removed by the filter. We do not have an oil filter system in our compressors to remove such contaminates. Compressor oil is designed to drop the contaminate out of suspension and onto the bottom of the crank case in order to keep it form damaging the bearings and rings.

Use motor oil "only" if you wish to do harm to your compressor. It is like slowly feeding poison. It may take a bit, but it will kill it's intended victem!

Knife

I forgot to add a very important part, why we don't use motor oil.

A motor vehicles oil is designed to float the particulate in the oil to be removed by the filter. We do not have an oil filter system in our compressors to remove such contaminates. Compressor oil is designed to drop the contaminate out of suspension and onto the bottom of the crank case in order to keep it form damaging the bearings and rings.

Use motor oil "only" if you wish to do harm to your compressor. It is like slowly feeding poison. It may take a bit, but it will kill it's intended victem!

Knife

Upvote 0

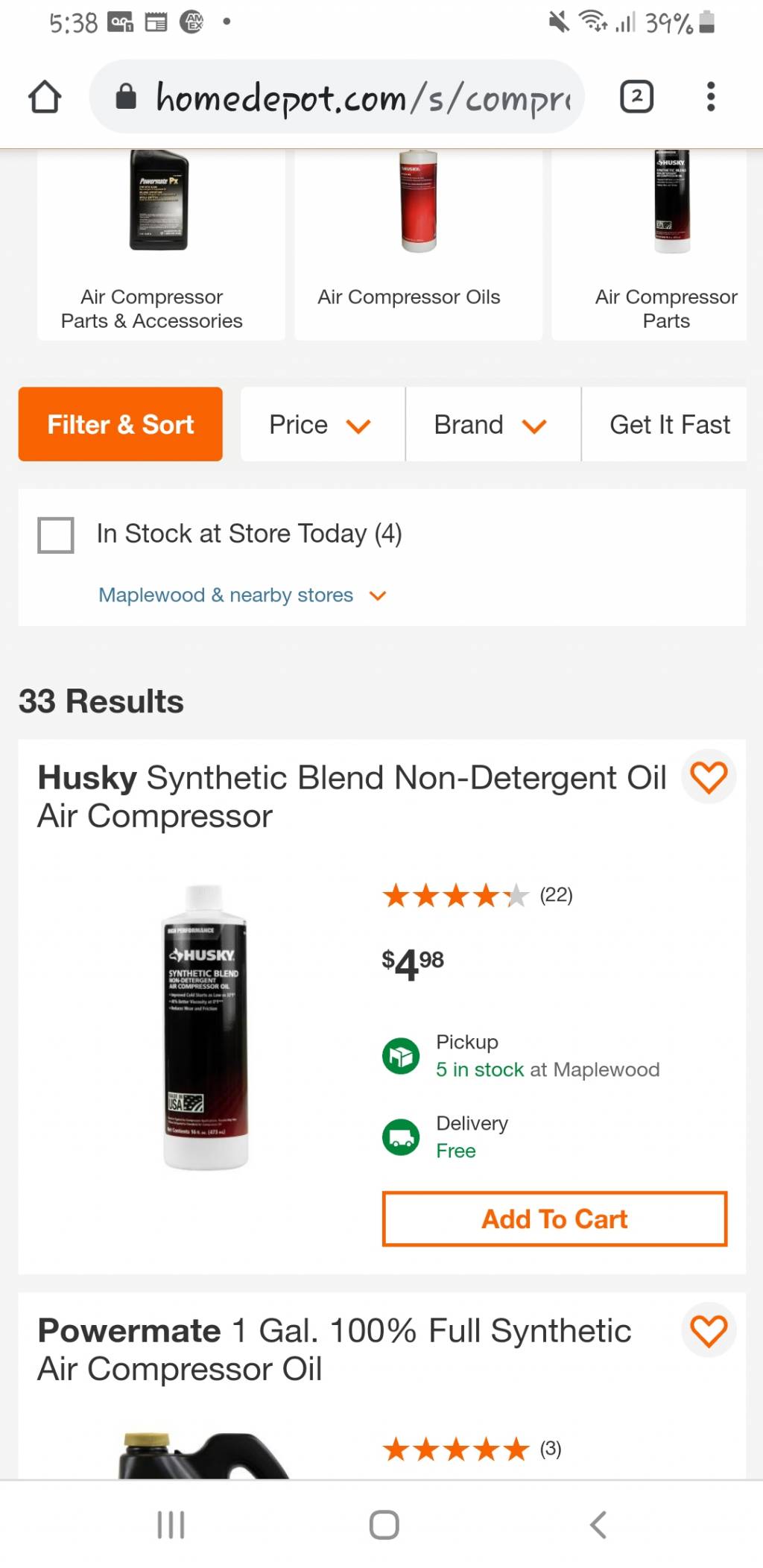

If you spend 3-5k on a compressor, its best to use high quality oil made for the compressor. But these are cheap Chinese compressor. A brand name company will recommend their high price oil, or you can void warranty. They want you to buy their $50 a quart oil duh lol. But most of the members here don't even own a 3-5k compressor. Most here own a yong heng or those 1k compressor also made in China. I own and use a yong heng and hatsan lighting for 3 years and use royal purple for a year till I switch over to the cheap $5 a bottle husky compressor oil at home depot. I'm still waiting for it to blow like some claim. My compressor still running just fine. So I speak from experience, as long as you are using synthetic compressor oil or non detergent compressor oil, you are fine. Don't need a pricy brand name compressor oil for these cheap compressor.

Upvote 0

Thanks knife for the info.. I did know what I didnt know... my compressor is up for a oil change. Just ordered some from nuvair...darn stuff is expensive to ship! Wow!! Beats a new compressor though

Upvote 0

most synthetic oils in the big box stores are hydrocarbon base ,as is group III,, group IV are the PAO bases,, and group V are the esters and silicone bases

knife is right on and the dispersants in motor oil holds the dirt in suspension, a bad property for our compressors but good for our dirty gasoline engines

A good read by Amsoil about bases https://blog.amsoil.com/are-all-synthetic-oil-groups-the-same-group-iii-vs-iv-vs-v/

if it cheap, it is group III I often look at MSDS for clues as to an oils base, cause the manufacture does not always tell you

knife is right on and the dispersants in motor oil holds the dirt in suspension, a bad property for our compressors but good for our dirty gasoline engines

A good read by Amsoil about bases https://blog.amsoil.com/are-all-synthetic-oil-groups-the-same-group-iii-vs-iv-vs-v/

if it cheap, it is group III I often look at MSDS for clues as to an oils base, cause the manufacture does not always tell you

Upvote 0

Cheaper compressors are mover susceptible to oil issues, or as we say in Texas, Here's you sign.

I fill two 88 cf bottles a day on average. No way I'm risking it! But then again, you can lead a horse to water-----

I fill two 88 cf bottles a day on average. No way I'm risking it! But then again, you can lead a horse to water-----

Upvote 0

Usually any oil is fine. Some even use car engine oil and it works fine for them. I tried hydraulic oil 46 like the manual recommended. I tired royal purple. I tired regular compressor oil for those shop compressor. All works fine. I can't tell a difference. All the oil really does is just lubricant the shaft. I dont think it matters which oil you go for. They all will work.

Where it all comes to a point is combustability!

The (low grade) engine oils will readily diesel and gumm/carbon up HP valves, thus causling seeping and reduced effiency.

The higher synthetic oils you use the less this nuisance will be!

So would you rather like a blood transfusion from a perfect AB match human or the content from an unripe coconut (used for sterile fluid during WWII!)!

Upvote 0