Debated if this is the right section or if it falls under "accessories" if I'm wrong, my apologies.

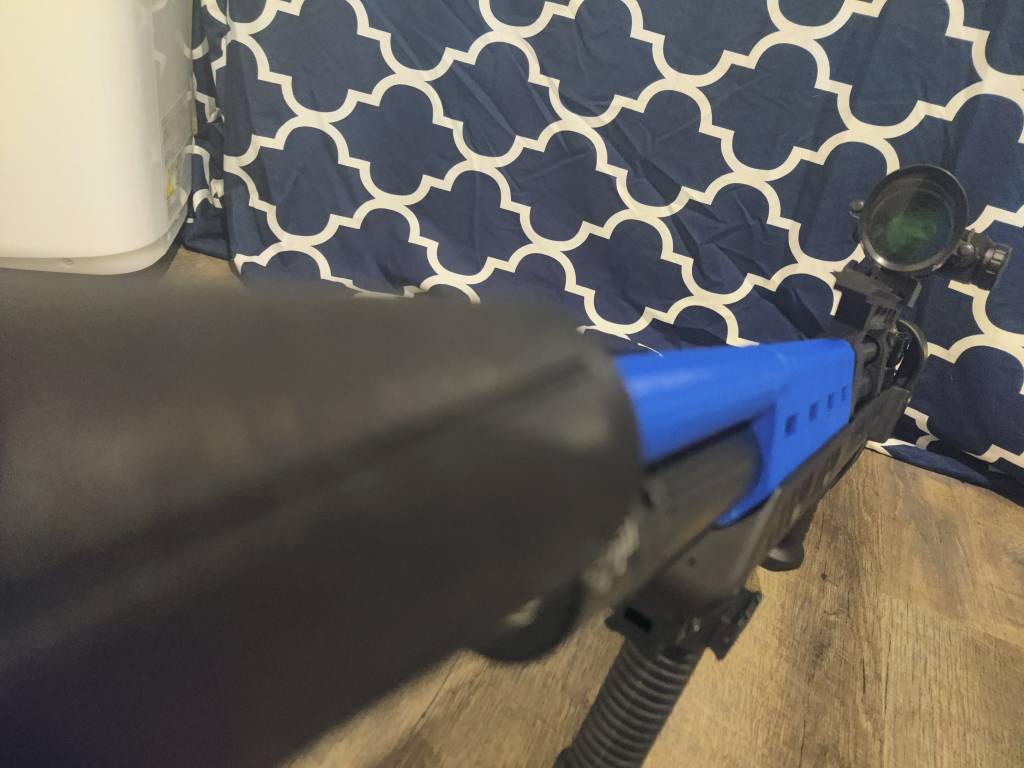

Thought I would share one of my prints. It's the first prototype. I plan to revise it a few things.

Future possible revisions:

#1 The blue tube with the barrel band will have more tactical appearance. Maybe add some rails, or faux vents.

#2 have complete bottom air tube covered. To match better with the upper hand guard.

#3 I'm iffy on this one. In the space between the upper scope mount and the stock was thinking to add some paneling.

#4 current rectangle vents will be switched to M-lok. More for style than function .

This is a low polly model. When I settle on a full design I'll do a final highpolly print. Obviously not in blue. Then I'll decide on a final material.

Be kind this a very rought draft of a concept I'm playing with.

Thought I would share one of my prints. It's the first prototype. I plan to revise it a few things.

Future possible revisions:

#1 The blue tube with the barrel band will have more tactical appearance. Maybe add some rails, or faux vents.

#2 have complete bottom air tube covered. To match better with the upper hand guard.

#3 I'm iffy on this one. In the space between the upper scope mount and the stock was thinking to add some paneling.

#4 current rectangle vents will be switched to M-lok. More for style than function .

This is a low polly model. When I settle on a full design I'll do a final highpolly print. Obviously not in blue. Then I'll decide on a final material.

Be kind this a very rought draft of a concept I'm playing with.