David I'm sorry to hear that you were so badly hurt. Do you think the small end or the filter end hit you? With so much damage it is hard to see what gave away first. Looking at the hose assembly it looks as if the filter broke off and took off like a rocket. When it reached the end of travel it pulled and stretched the hose until it broke the hose off, I assume that's why the spring looks stretched.

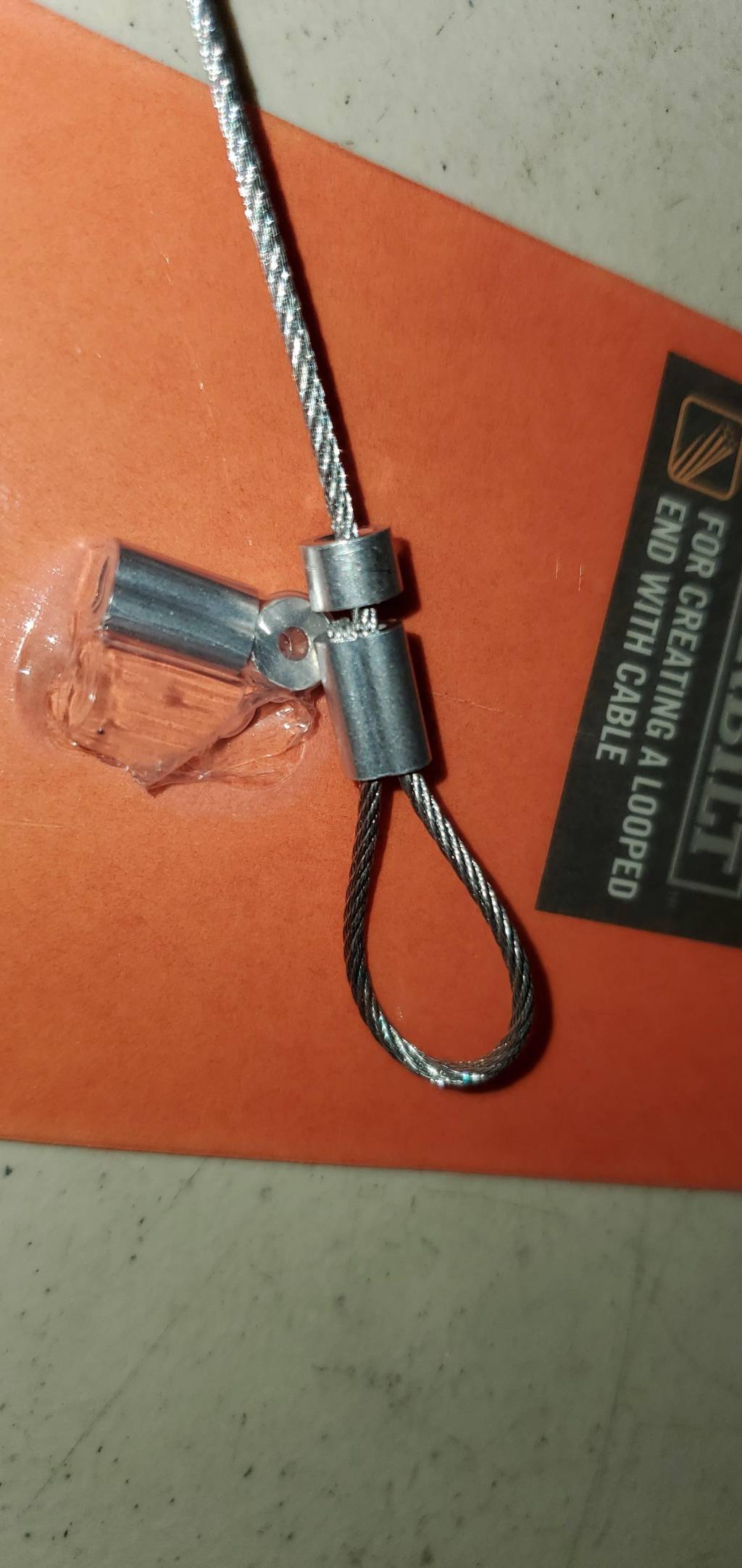

Again sorry for your misfortune. I want to make a tether at both ends of my hose so if something like this were to happen to me, hopefully no one will get hurt. One end of the tether would attach to the bottle the other to the attached end of the hose. On the other end where the AG is to be filled maybe attach to a sand bag or the AG itself.

I have not thought it through yet but at least each end would not fly freely to hit someone.

Allen

Again sorry for your misfortune. I want to make a tether at both ends of my hose so if something like this were to happen to me, hopefully no one will get hurt. One end of the tether would attach to the bottle the other to the attached end of the hose. On the other end where the AG is to be filled maybe attach to a sand bag or the AG itself.

I have not thought it through yet but at least each end would not fly freely to hit someone.

Allen

Upvote 0