You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

AEA Post Your AEA Challenger Mods (Not Pro Version)

- Thread starter heavy-impact

- Start date

It's only spent a few days in it's new home since the owner acquired it a couple months back. My son is just letting me play with it.I think that Gun likes it’s new home.

Upvote 0

Assembled the balance is right at the trigger. The length of pull is 13 1/4" but feels better here. It still weighs just about 11 lbs like this.

Upvote 0

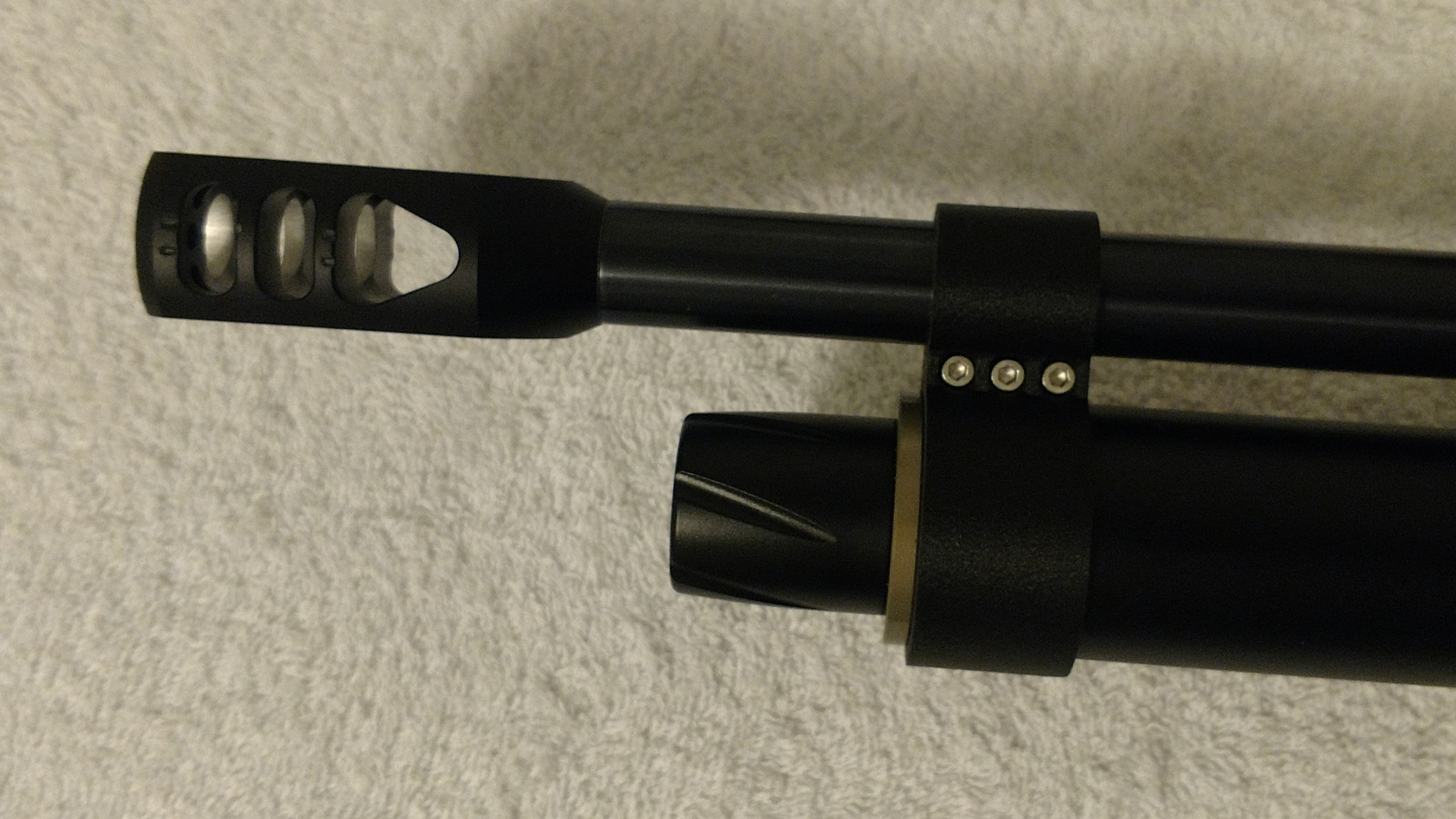

Tonight's $25.00 non-pro experiment was a success. With the tanker style muzzle brake it is now dead in the hand at the shot. Before this add-on the 457 was a mule and would scope someone not paying attention.

The barrel threads are M18-1.0 and requires a 17 mm drill. After squaring up the existing small bore and locking it down I step drilled the bore to .500" and then did the drilling and tapping of the threads. It needs a good barrel band next because it has always been whippy and inaccurate.

The barrel threads are M18-1.0 and requires a 17 mm drill. After squaring up the existing small bore and locking it down I step drilled the bore to .500" and then did the drilling and tapping of the threads. It needs a good barrel band next because it has always been whippy and inaccurate.

Upvote 0

Very nice work Airgun-hobbyist on the muzzle brake. I have the HP MAX .45 $ .50 and a 17mm drill and m18-1.0 tap but where did you purchase the brakes from? Thank you

Upvote 0

Do you weld?It needs a good barrel band next because it has always been whippy and inaccurate.

Upvote 0

eBay. You don't need one with the top cut outs, in my opinion. As this would unnecessarily push down when the gun only pushes back. (There's not as violent a blast as a powder burner.)Very nice work Airgun-hobbyist on the muzzle brake. I have the HP MAX .45 $ .50 and a 17mm drill and m18-1.0 tap but where did you purchase the brakes from? Thank you

Upvote 0

Weld a rig to measure the barrel. Two of my big bore AEA barrels (factory and replacement) had run outs of 0.043" and 0.025". I improved them quite a bit, but you need to be able to measure the run out. Barrel band did not help in my case.It's easier to 3d print but what do you have in mind to weld?

Upvote 0

When you striped it down and sanded, what color was the natural wood underneath? Was it blonde colored wood or a darker one? I'm thinking about refinishing mine in a lighter shade to not be so dark. Great work on yours man!Non-pro woodworking and refinish to put the 457 Challenger Bullpup's heavy stock on a needed diet and balance the weight some...

Tools and chemicals: antique electric jig saw and thin wood bit, electric drill with 50 grit sanding disk, Dremel Tool with long spiral carbide bit, Diablo SandNet sandpaper sheets 120-320 grits, paint and varnish remover used with 00 steel wool, oil based stain and Minwax polyurethane.

I cut almost 1 1/2" of wood off the back end and contoured it so the length of pull is close to 14" now, and nearly as short as I could make it with the mounting screw hole The jig saw was used to cut the excess center wood out, following the contour lines. The drill and 50 grit sanding disk hogged wood off the fat fore stock, loosing about half inch of width total, and helped to round and flow the inside corners to match the contour lines. The Dremel Tool and long spiral fluted carbide bit was used in the center section to work the radiuses and angles smooth that could not be gotten with the sanding disk. With everything close to the look I wanted, I broke out the new Diablo sandpaper sheets I found at Ace Hardware. The Diablo SandNet sandpaper is a sweet bit of Swedish technology that really helped to remove wood and get the profiles and grip corners rounded smooth and in a hurry too.

I left the factory stained finish on until the end to use as a working guide to keep the sides even, stripping it before the final finish sanding. I stained the white beech wood with my golden oak and dark walnut oil based stain mixture and put the Minwax polyurethane on it in several coats. The finish is really the hardest part to get right, because I am not a woodworker. I've gone over it a half dozen times now and it's drying again after this picture. We'll see in a few days if I looks good enough to hunt.

View attachment 421594

Upvote 0

Look here: https://www.airgunnation.com/threads/shot-my-510-challenger-bullpup.1297761/page-2#post-1591313When you striped it down and sanded, what color was the natural wood underneath? Was it blonde colored wood or a darker one? I'm thinking about refinishing mine in a lighter shade to not be so dark. Great work on yours man!

Upvote 0

Yea, I read your entire posts. Was looking for a view that showed more surface being stripped down but thank you. I think I'll try a lighter stain. I can always do it again if I don't like it! Lol. Thanks for replying.

Upvote 0

I didn't take any pictures of the whole sanded stock. Raw, it was a bone white with very light brown specs. It looks like beech wood. In the attached image of the inletting, (I did this to make room for the trigger assembly that was hitting the stock) the raw wood shows up as a white/yellow and darkening the specs some with just Minwax polyurethane (which added the yellow tint).When you striped it down and sanded, what color was the natural wood underneath? Was it blonde colored wood or a darker one? I'm thinking about refinishing mine in a lighter shade to not be so dark. Great work on yours man!

Upvote 0

More hand drilling and filing on the muzzle brake today... The bottom was drilled and filed to make slots that match the top. This will allow the air blast to blow out evenly on all four sides. Before this mod, the top porting put unnecessary downward pressure on the barrel when shot. There seems to be even less barrel oscillating now.

Upvote 0

Awesome man! I'm definitely going to sand mine down and apply a medium stain neither light or dark, something in between. I've got the standard shrouded Bullpup in 30 cal and I'm really enjoying it. How are you liking yours?

Upvote 0

I love it, looks fantastic. Bravo man!Non-pro woodworking and refinish to put the 457 Challenger Bullpup's heavy stock on a needed diet and balance the weight some...

Tools and chemicals: antique electric jig saw and thin wood bit, electric drill with 50 grit sanding disk, Dremel Tool with long spiral carbide bit, Diablo SandNet sandpaper sheets 120-320 grits, paint and varnish remover used with 00 steel wool, oil based stain and Minwax polyurethane.

I cut almost 1 1/2" of wood off the back end and contoured it so the length of pull is close to 14" now, and nearly as short as I could make it with the mounting screw hole The jig saw was used to cut the excess center wood out, following the contour lines. The drill and 50 grit sanding disk hogged wood off the fat fore stock, loosing about half inch of width total, and helped to round and flow the inside corners to match the contour lines. The Dremel Tool and long spiral fluted carbide bit was used in the center section to work the radiuses and angles smooth that could not be gotten with the sanding disk. With everything close to the look I wanted, I broke out the new Diablo sandpaper sheets I found at Ace Hardware. The Diablo SandNet sandpaper is a sweet bit of Swedish technology that really helped to remove wood and get the profiles and grip corners rounded smooth and in a hurry too.

I left the factory stained finish on until the end to use as a working guide to keep the sides even, stripping it before the final finish sanding. I stained the white beech wood with my golden oak and dark walnut oil based stain mixture and put the Minwax polyurethane on it in several coats. The finish is really the hardest part to get right, because I am not a woodworker. I've gone over it a half dozen times now and it's drying again after this picture. We'll see in a few days if I looks good enough to hunt.

View attachment 421594

Upvote 0

Tonight's non-pro Challenger barrel band mod, brought to you and inspired by @heavy-impact! Testing and tuning for it's final location along the bore/cylinder comes next.

Upvote 0