One of my sons picked up this preowned AEA Challenger bullpup in .30 cal with the 32" barrel and I've been fiddling with it the last few weeks making modifications to correct some of it's shortcomings. I've posted some of these in other threads but I thought I'd put it all in one thread to make the info easier for other challenger owners to find.

If you own an AEA challenger (not the Pro versions) with modifications post yours here too, any caliber.

One bad thing about the .30 cal is that it doesn't have a cocking lever. It has a short little bolt handle that can be difficult for some people to use especially with the heavy hammer spring installed. The gun doesn't cock until the last mm of travel and most people have to put their thumb on the back of the receiver to get the job done.

My fix. I turned a new handle 18mm x 60mm from 6061T6 aluminum and the shaft 7.25mm M6x1.25 thread from 303 stainless. I tried a knurled one but smooth feels way better.

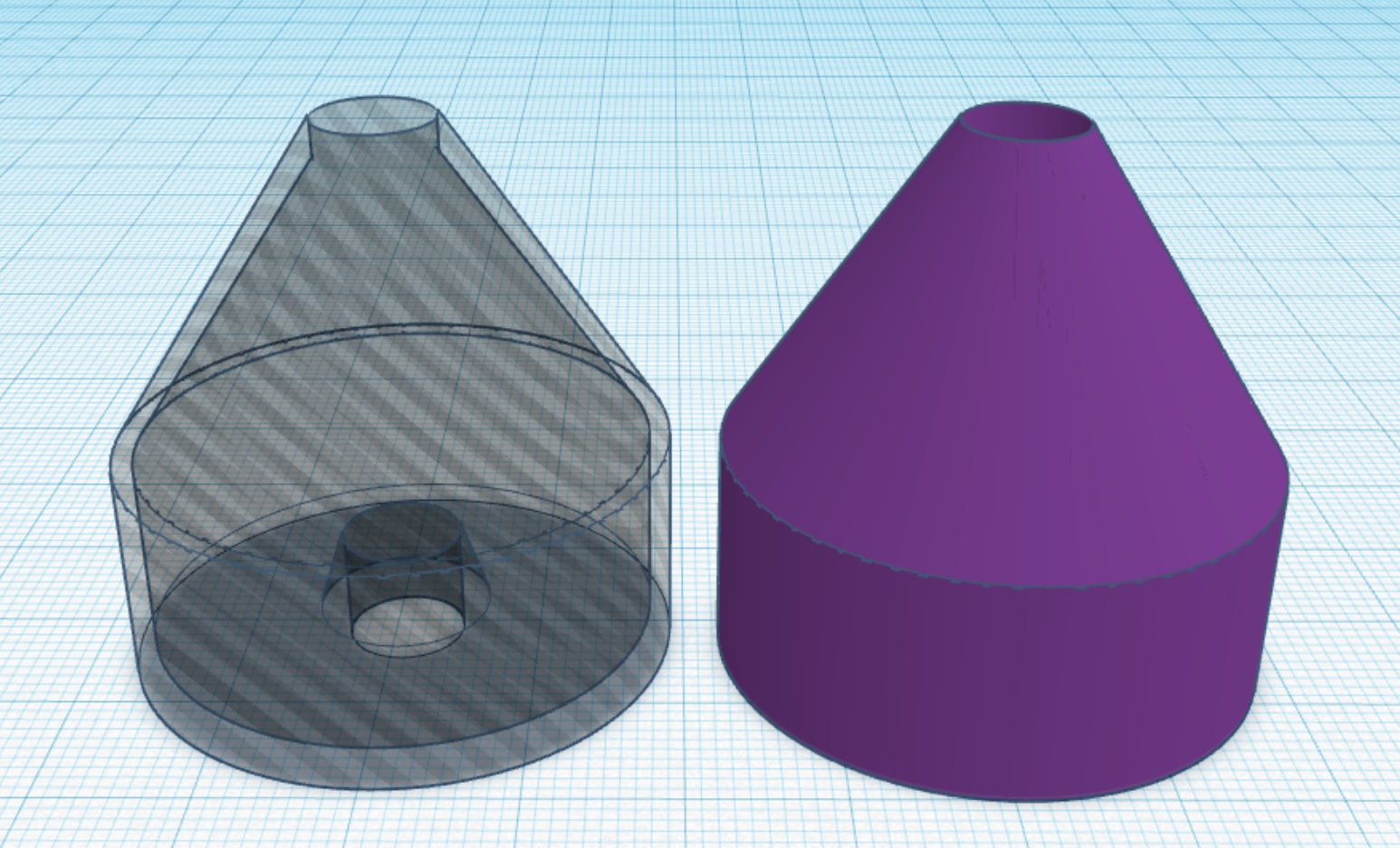

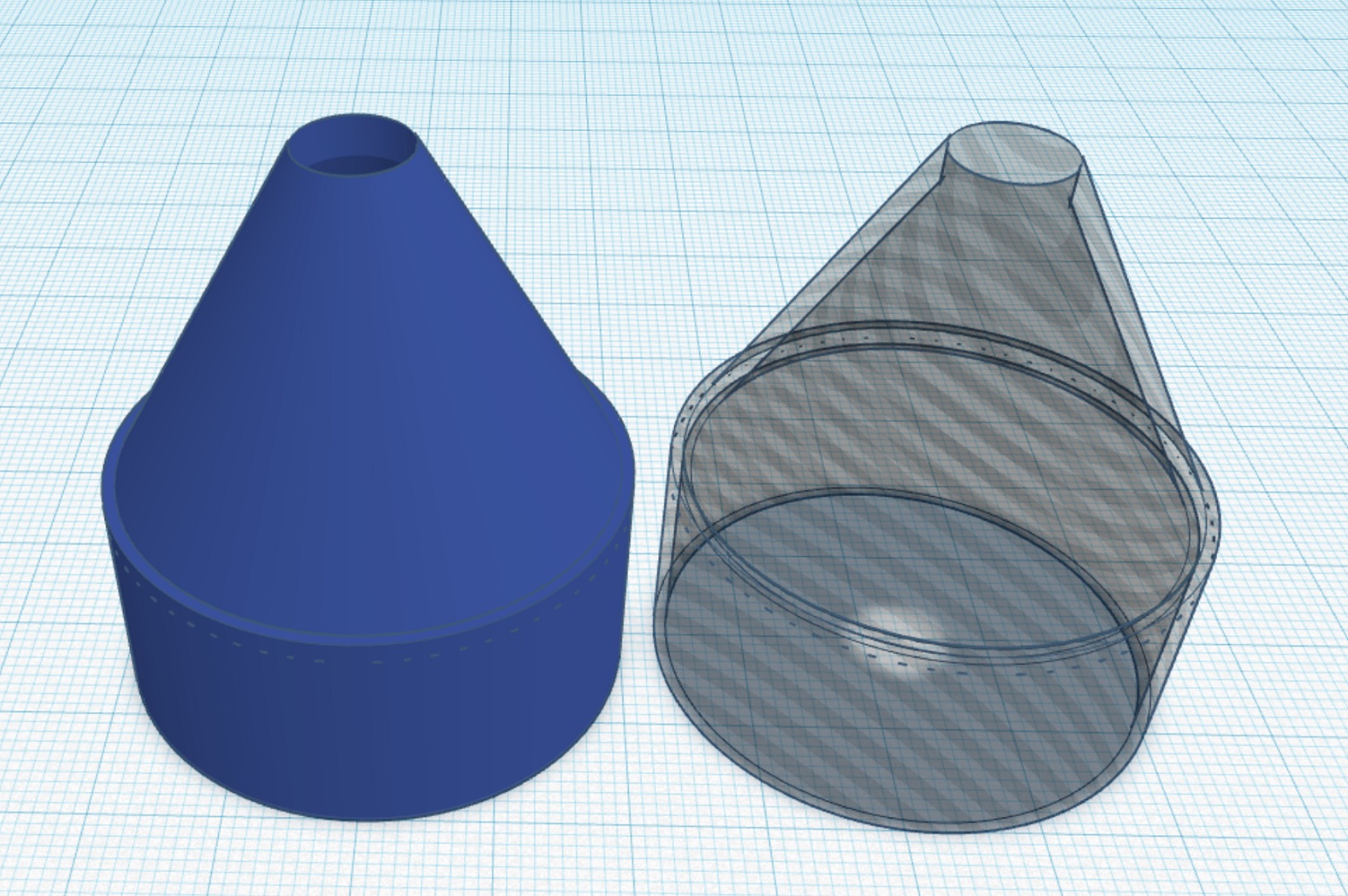

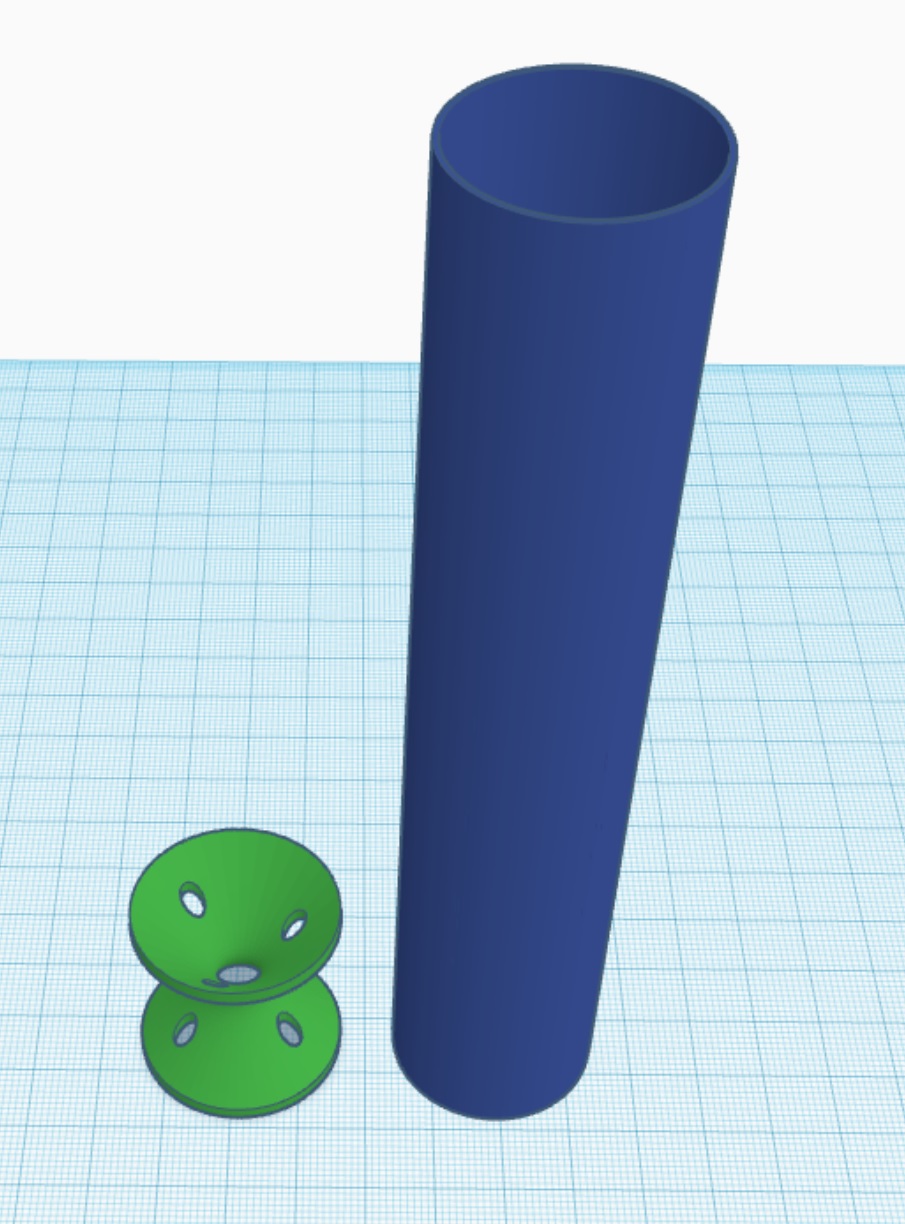

These unregulated airguns make big power with 100+ grain slugs and they're loud without a suppressor. I turned this one from 6061 aluminum measuring 40mm ID x 194mm.

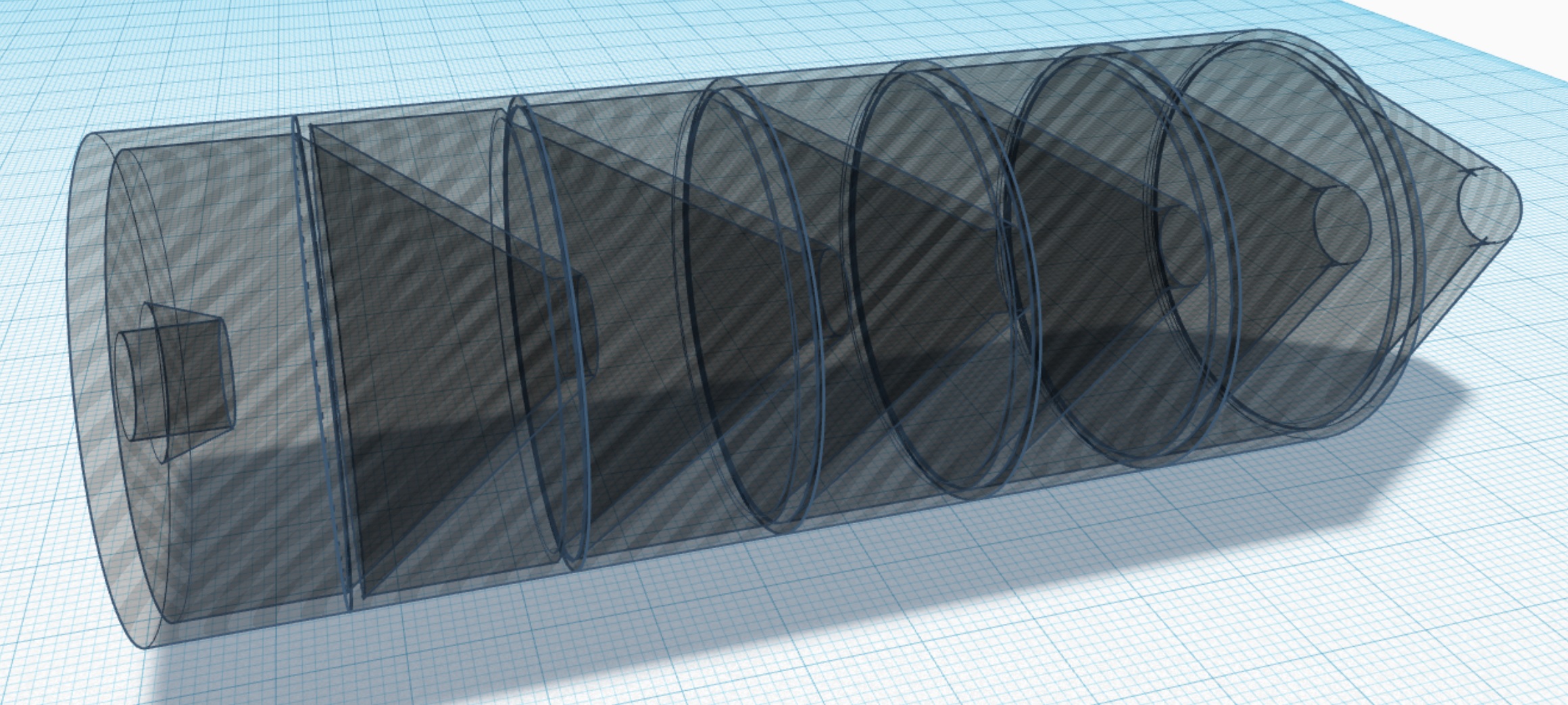

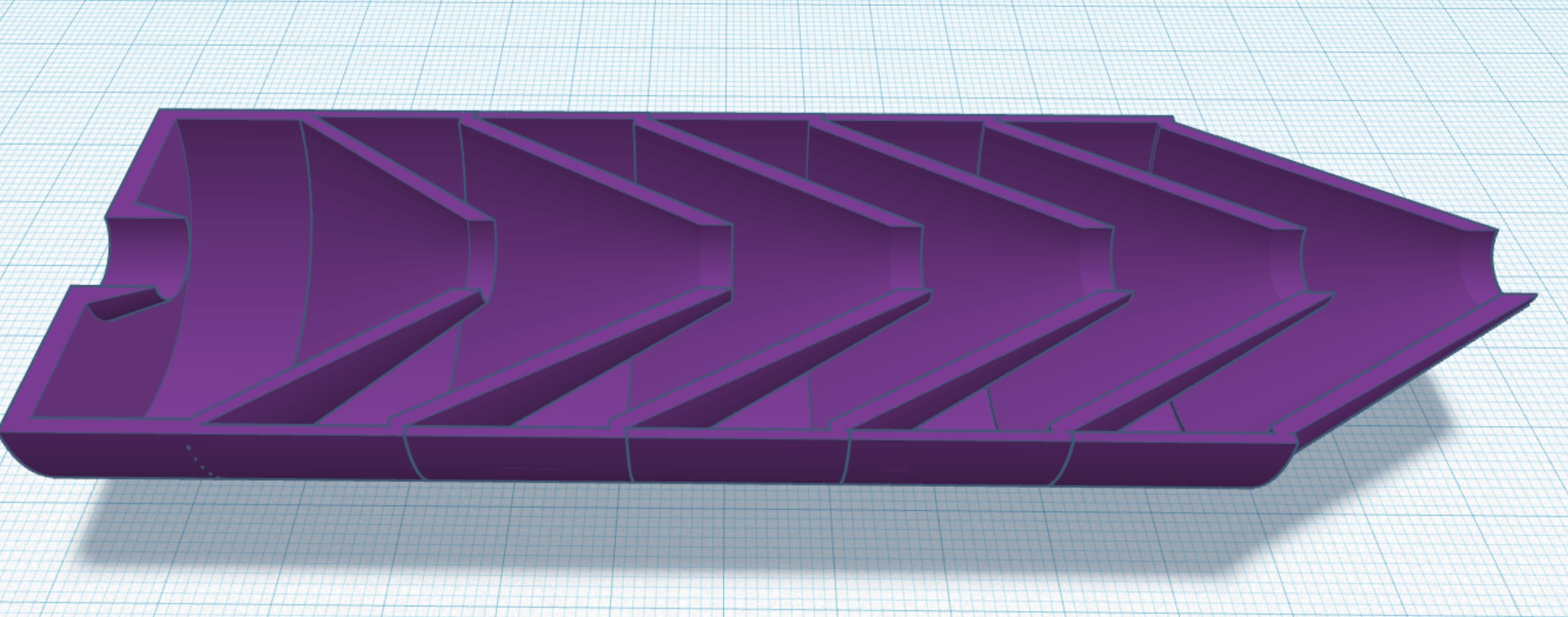

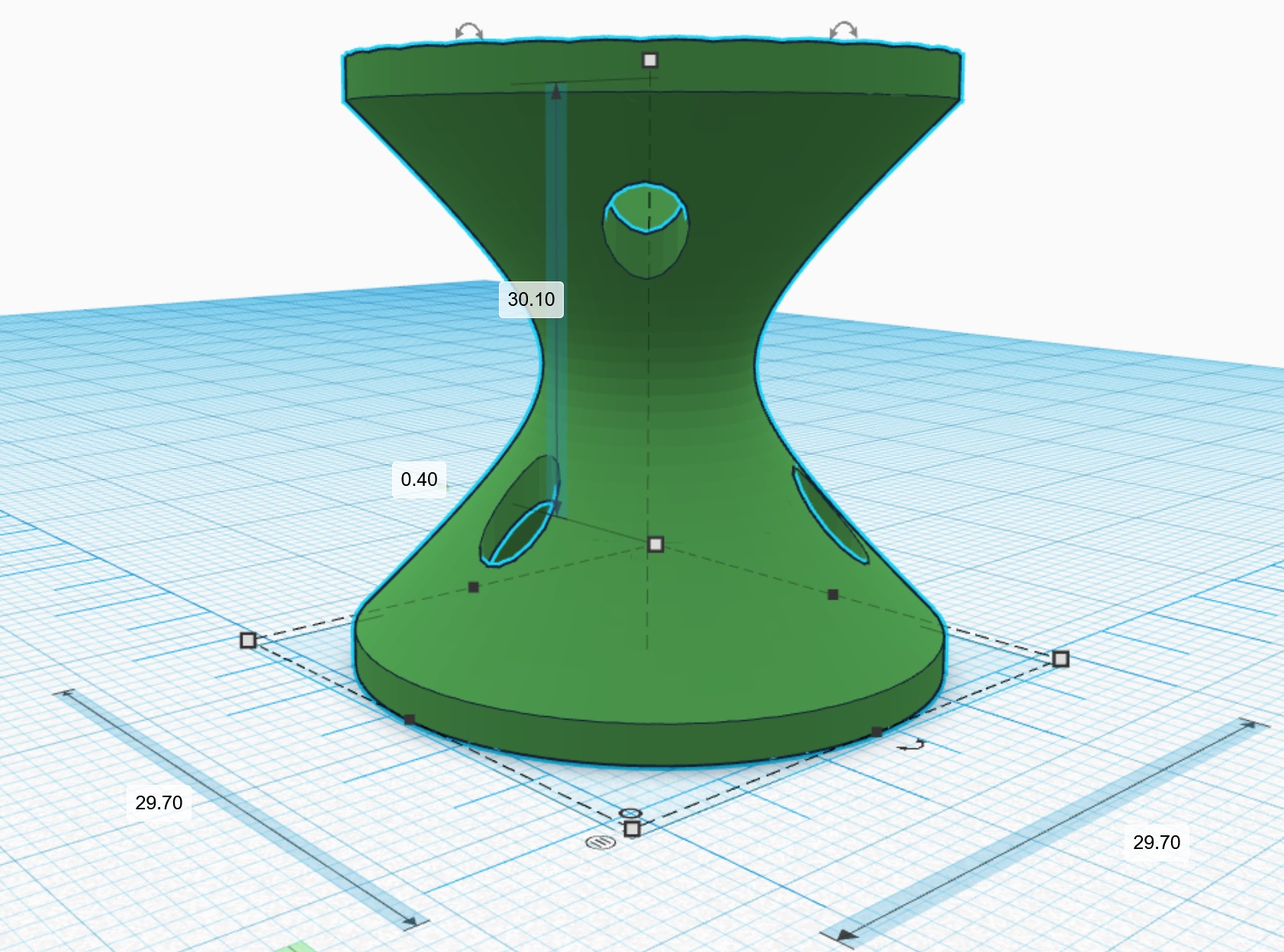

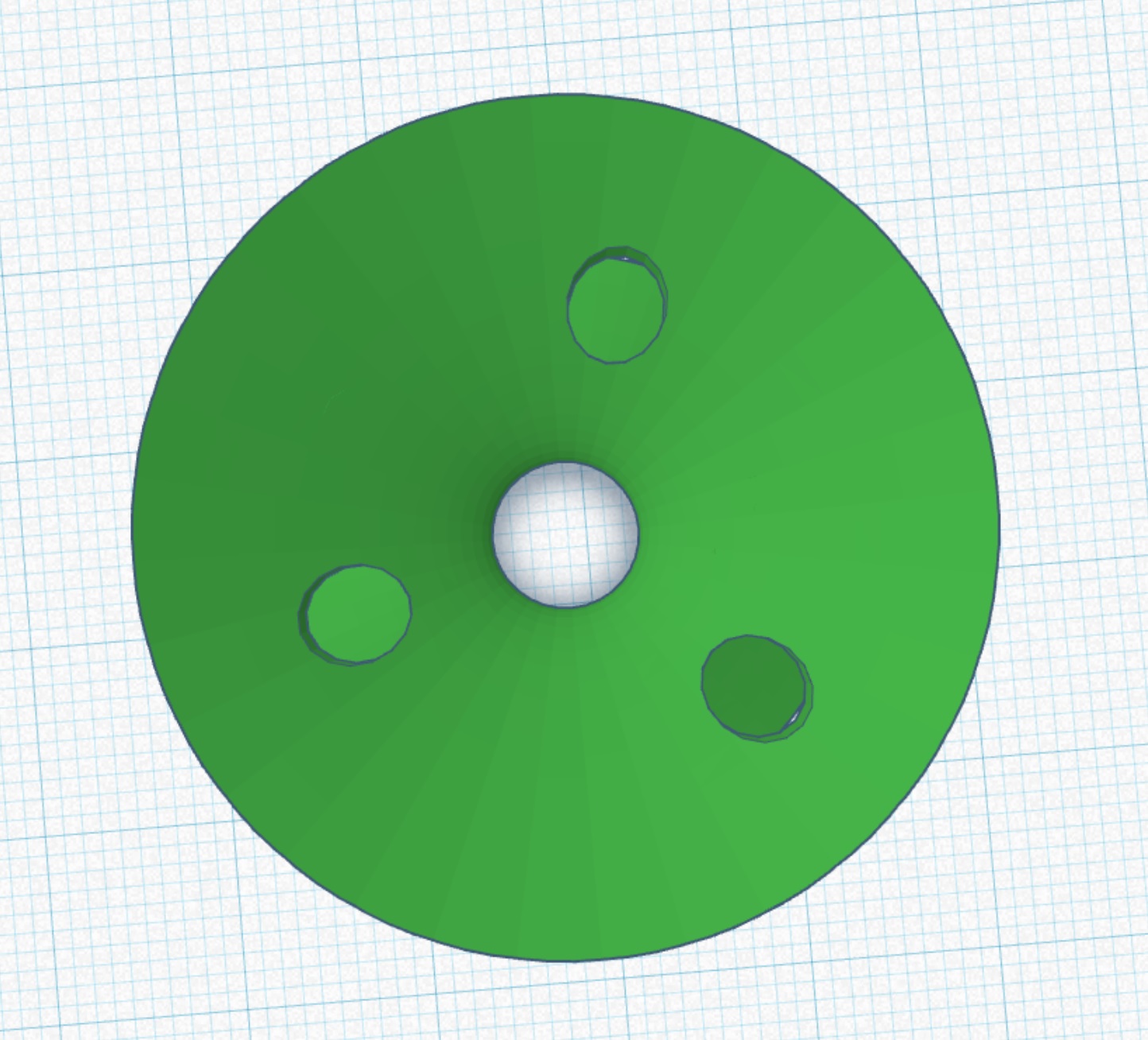

It's an open can style using air stripper baffles 3d printed from PETG material for toughness. I tested the baffles with different clearances and settled on 8.2mm for the first 5 and 8.3mm for the exit baffle. Sounds like a 60p nail gun when you keep the slugs subsonic. Clear view and cutaway pics of the baffles to see how high velocity air gets stripped away from the slug and delayed via a longer travel path. This type has much less turbulence and is more effective than the aluminum core type with felt wrap because the high velocity air passes the projectile in those. If you have access to a lathe this type suppressor costs less than $20 to produce.

Next problem was PING. I designed this de-pinger and spacer to take the ping out without affecting power.

The depinger must be printed solid/100% infill. The spacer keeps it 150mm above the valve. I printed this in PETG material for toughness.

Printers vary so be sure both parts fit in the tube just slightly snug. You need to resize in your slicer and reprint if not.

Installation...

1- Degass the gun by backing the gauge out until the air leaks out.

2- Unscrew the air tube cap that the gauge is in.

3- Put the spacer in, put the de-pinger in next then push them down the tube carefully until they stop.

4- Reassemble in reverse order.

5- Cock the gun and put the safety on to keep the valve closed when airing up from empty, otherwise air will go out the barrel without building pressure.

Download from thingiverse

I wanted to use a bipod and have better barrel support so I designed this barrel band with a picatinny rail. It's printed in carbon fiber nylon material to make it almost as strong as aluminum and is free to download and use as you wish. https://www.thingiverse.com/thing:6273712

The trigger on these airguns is super heavy so I did a trigger job to bring the single stage trigger down to less than a pound but I didn't take pictures.

I'll be designing a cheek rest soon.

If you own an AEA challenger (not the Pro versions) with modifications post yours here too, any caliber.

One bad thing about the .30 cal is that it doesn't have a cocking lever. It has a short little bolt handle that can be difficult for some people to use especially with the heavy hammer spring installed. The gun doesn't cock until the last mm of travel and most people have to put their thumb on the back of the receiver to get the job done.

My fix. I turned a new handle 18mm x 60mm from 6061T6 aluminum and the shaft 7.25mm M6x1.25 thread from 303 stainless. I tried a knurled one but smooth feels way better.

These unregulated airguns make big power with 100+ grain slugs and they're loud without a suppressor. I turned this one from 6061 aluminum measuring 40mm ID x 194mm.

It's an open can style using air stripper baffles 3d printed from PETG material for toughness. I tested the baffles with different clearances and settled on 8.2mm for the first 5 and 8.3mm for the exit baffle. Sounds like a 60p nail gun when you keep the slugs subsonic. Clear view and cutaway pics of the baffles to see how high velocity air gets stripped away from the slug and delayed via a longer travel path. This type has much less turbulence and is more effective than the aluminum core type with felt wrap because the high velocity air passes the projectile in those. If you have access to a lathe this type suppressor costs less than $20 to produce.

Next problem was PING. I designed this de-pinger and spacer to take the ping out without affecting power.

The depinger must be printed solid/100% infill. The spacer keeps it 150mm above the valve. I printed this in PETG material for toughness.

Printers vary so be sure both parts fit in the tube just slightly snug. You need to resize in your slicer and reprint if not.

Installation...

1- Degass the gun by backing the gauge out until the air leaks out.

2- Unscrew the air tube cap that the gauge is in.

3- Put the spacer in, put the de-pinger in next then push them down the tube carefully until they stop.

4- Reassemble in reverse order.

5- Cock the gun and put the safety on to keep the valve closed when airing up from empty, otherwise air will go out the barrel without building pressure.

Download from thingiverse

I wanted to use a bipod and have better barrel support so I designed this barrel band with a picatinny rail. It's printed in carbon fiber nylon material to make it almost as strong as aluminum and is free to download and use as you wish. https://www.thingiverse.com/thing:6273712

The trigger on these airguns is super heavy so I did a trigger job to bring the single stage trigger down to less than a pound but I didn't take pictures.

I'll be designing a cheek rest soon.

Last edited: