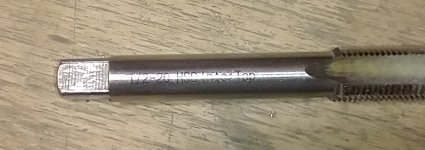

30mm x 28mm x 126mm nominal on the length. You can get 4 pieces out of a 500mm section if you hold your mouth right. You might have to scale it a bit in the slicer. 27.93 is just right for my purposes from my RESIN printer. Those caps are a tight fit. I use a jig I designed to pull the attachment end into place. It is a hard job without that tool. Threads on the attachment need to be chased out with a tap. I should have mentioned you will need a helicoil as well. MCMaster-Carr. They aren't cheap.Have the files.

Now to slice. Seem to be getting an unexpected internal perimeter, although I have set them to 0 in the slicer. I'll have to muck about with that to see what's causing this. Edit: Found out how to fix that.

ID is 28mm? Just confirming before sourcing CF tubing. Found some for $30.50 for 1 meter. Need to order before Chinese New Years, or it will be delayed a while.

Last edited:

Upvote 0