Is there a formula that models the appropriate plenum volume, pressure, barrel volume to compare/contrast sizes and pressures? Say I was going to build a custom plenum for a rifle with a dedicated tune and wanted to know what 1cc more or 1cc less plenum space would do. Is there a function or formula to model with?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Tuning Plenum size formula/calculation ?

- Thread starter SqrlHntr

- Start date

I've heard a "general rule" is 1cc per FPE, but recent advancements(longer than normal barrels, different valving, transfer ports) may be able to make use of a higher ratio.

Upvote 0

A guideline of 0.5cc per fpe works well for in-tube regulators. More is better for efficiency, up to 1.0cc per fpe, but you’re trading off a portion of the reservoir volume for plenum with in-tube setups so the 0.5cc per fpe will produce a better shot count.

By that I mean contrasted against something like a bottle conversion where the whole air tube is available to act as the plenum.

By that I mean contrasted against something like a bottle conversion where the whole air tube is available to act as the plenum.

Upvote 0

.5 cc / fpe but with the same setpoint, correct? I guess what im trying to get at is if plenum volume x set at y psi with a z barrel volume produces say 950fps, then decreasing volume x needs an increase in psi to compensate and keep at 950? Inversely, an increase in plenum volume would then need a decrease in setpoint, correct? Can the setpoint change needed to compensate for a larger or smaller volume be calculated?

Upvote 0

At 0.5cc per fpe, you will need about 10% higher pressure to get the same power as you would with a larger plenum (i.e. using 1cc per fpe).

Upvote 0

At 0.5cc per fpe, you will need about 10% higher pressure to get the same power as you would with a larger plenum (i.e. using 1cc per fpe).

You rock. Thanks!

Upvote 0

No problem. BTW you may want to look up Bob Sterne’s articles for Hard Air Magazine (online)...many of the common questions about PCP tuning and modifications are covered.

Upvote 0

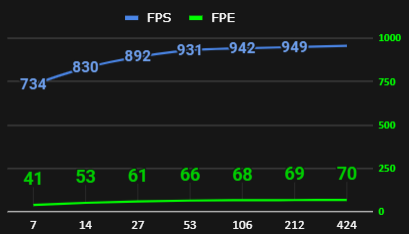

Here is a simple graph with various plenum sizes ranging from 7 CC to 424 CC on my personal rifle (.25 cal with .225" ports)

Another way to view it, if you can calculate pressure usage per shot in CC's, you can estimate how much pressure drop occurs in your plenum during your shot, so a 5cc shot would use 10% in 50cc's, or 20% in 25cc's, which would be a 200 psi drop @ 2000 psi, or a 400 psi drop @ 2000 psi, each creating an average pressure of 1900, and 1800 psi...which is why larger plenums help greatly, diminishing returns occur greatly after the 1.5 cc per fpe mark as shown in the graph.

Another way to view it, if you can calculate pressure usage per shot in CC's, you can estimate how much pressure drop occurs in your plenum during your shot, so a 5cc shot would use 10% in 50cc's, or 20% in 25cc's, which would be a 200 psi drop @ 2000 psi, or a 400 psi drop @ 2000 psi, each creating an average pressure of 1900, and 1800 psi...which is why larger plenums help greatly, diminishing returns occur greatly after the 1.5 cc per fpe mark as shown in the graph.

Upvote 0

As an absolute power junkie.. ontopic of in tube regs..

Currently working on an Artemis P15 and realized i need ample plenum volume for this little 22 to become all it can be. So against better judgement i decided on placing a plenum bolted to the integral trigger/barrrel band/scope assy.

As the tube is 30mm diameter i´m planning on using regular scope rings and a rail to pull it off.

Material used is common 6086 in 30*3mm.

Upvote 0

Racing,

I wouldn’t use that. The wall thickness looks to be way too thin not to mention the pressure on the endcaps . If you want big power from that rifle , I’d be getting rid of the regulator and source a stiffer hammer spring.

I wouldn’t use that. The wall thickness looks to be way too thin not to mention the pressure on the endcaps . If you want big power from that rifle , I’d be getting rid of the regulator and source a stiffer hammer spring.

Upvote 0

It´s a 30*3 out of 6086 aluminium. (In other words thicker than the stock air tank as far as gauge)

N yes. I´m an engineer.

N yes. I´m an engineer.

Upvote 0

FWIW. I decided on going the reg route. Thus the passages has been reamed out. Hammer spring in turn? No. A new hammer and a spring for an Impact, which is wound on 1,4 vs the stock 1,1 gauge.

Went full retard on the poppet n seal housing, making it two part. The plastics got omitted though at the benefit of JM-7 bearing bronze. Gun is up and running, still need to handle a few minor issues.

..with 25,4´s. Which is simply to small a number as the intent is for 34 grainers. So the hunt continues. Highest No that night 1017. This though on the stock hammer n spring.

Just did an Artemis PR-900 "cost a nothing" the other week, and that turns an easy 1050 with the same ammo. Content where that is at though, in contrast to this P15. Sports a Lothar Walter barrel a tad longer too, the P15 that is.

So yeah. "Alternative" placement of a plenum is what it is. Plan to bolt it to the stock bracket for the scope/trigger/barrel band with a sorts of weaver and then use regular rings as the tube is 30mm.

Upvote 0

I’m definitely horrible at math but I was thinking about this same thing the other day with my Caiman X. It was shooting 17.5gr slugs at 903fps when I got it. I wanted to tune it to around 20fpe, but the reg doesn’t adjust low enough with out completely closing off. So my thought was machine a spacer for inside the plenum to basically make the plenum smaller. What would running the same pressure with a smaller plenum do to the power output? I believe factory reg setting is around 110bar.

Upvote 0

What would running the same pressure with a smaller plenum do to the power output? I believe factory reg setting is around 110bar.

Lower velocity and poorer efficiency. Answered in more detail in your topic a few days ago:

https://www.airgunnation.com/topic/plenum-volume/#post-1178272

Upvote 0