The other day I was just mentioning about some plastic or teflon pallet/slug. But I was thinking if such can be made in precision with lead core for weight it may serve a good purpose, in lesser air pressure one might achieve higher velocity. Teflon once locked into the rifling might glide smoother, with no carbon dust emission for subsequent shots, airgun has no firepower so heat may not be an issue. Come to think of ur barrel might even last forever!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Other Plastic pallet theory

- Thread starter Dr.Kera

- Start date

Pure Teflon is way too soft ! It's VERY likely to deform to a blob when the air pressure hits it .

Now, as you say, maybe a thin coating of Teflon on a standard shaped, lead pellet, that might be something to study.

I remember many years ago, the firearm industry was looking at plastic coated bullets. Don't recall the exact type of plastic/polymer that they used but they were available for purchase for a few years. Helped lower lead fouling, and helped the bullet go a little faster down the barrel.

I never tried any.

Mike

Now, as you say, maybe a thin coating of Teflon on a standard shaped, lead pellet, that might be something to study.

I remember many years ago, the firearm industry was looking at plastic coated bullets. Don't recall the exact type of plastic/polymer that they used but they were available for purchase for a few years. Helped lower lead fouling, and helped the bullet go a little faster down the barrel.

I never tried any.

Mike

Upvote 0

Oh! Ty was presuming only it's in my headPure Teflon is way too soft ! It's VERY likely to deform to a blob when the air pressure hits it .

Now, as you say, maybe a thin coating of Teflon on a standard shaped, lead pellet, that might be something to study.

I remember many years ago, the firearm industry was looking at plastic coated bullets. Don't recall the exact type of plastic/polymer that they used but they were available for purchase for a few years. Helped lower lead fouling, and helped the bullet go a little faster down the barrel.

I never tried any.

Mike

Upvote 0

There are still a range of pellets with a plastic skirt available, Elko still make them. https://www.elko.hu/

Not that i would even dare to try them

Not that i would even dare to try them

Upvote 0

Faster isn’t necessarily better or more accurateThe other day I was just mentioning about some plastic or teflon pallet/slug. But I was thinking if such can be made in precision with lead core for weight it may serve a good purpose, in lesser air pressure one might achieve higher velocity. Teflon once locked into the rifling might glide smoother, with no carbon dust emission for subsequent shots, airgun has no firepower so heat may not be an issue. Come to think of ur barrel might even last forever!

Upvote 0

Indeed.

If i shoot my 13 gr slugs 100 FPS faster, i can barely keep all 10 shots on a 3" target at 92 yards.

If i shoot them at the optimal slower speed i only need some of the space on a 2" target.

If i shoot my 13 gr slugs 100 FPS faster, i can barely keep all 10 shots on a 3" target at 92 yards.

If i shoot them at the optimal slower speed i only need some of the space on a 2" target.

Upvote 0

Yes Mike you are kinda correct. The industry was not looking into it but it was a side affect of us boolit caster. It is powder coat. It contains the lead and while doing so does provide a slicker less resistant surface than copper or traditional lubes allowing higher speeds to be achieved. Once again faster is not always better if you care about the object you are attempting to hit. Given the fact that air guns do not have throating issues a barrel already lasts forever and does not have to be subject to powder burners issues. I guess you could get a few extra feet per second out of a PC boolit with less air. I would feel this would work better in the big bore stuff coming out of the lesser power guns like the AEA stuff.I remember many years ago, the firearm industry was looking at plastic coated bullets. Don't recall the exact type of plastic/polymer that they used but they were available for purchase for a few years. Helped lower lead fouling, and helped the bullet go a little faster down the barrel.

I never tried any.

Mike

Upvote 0

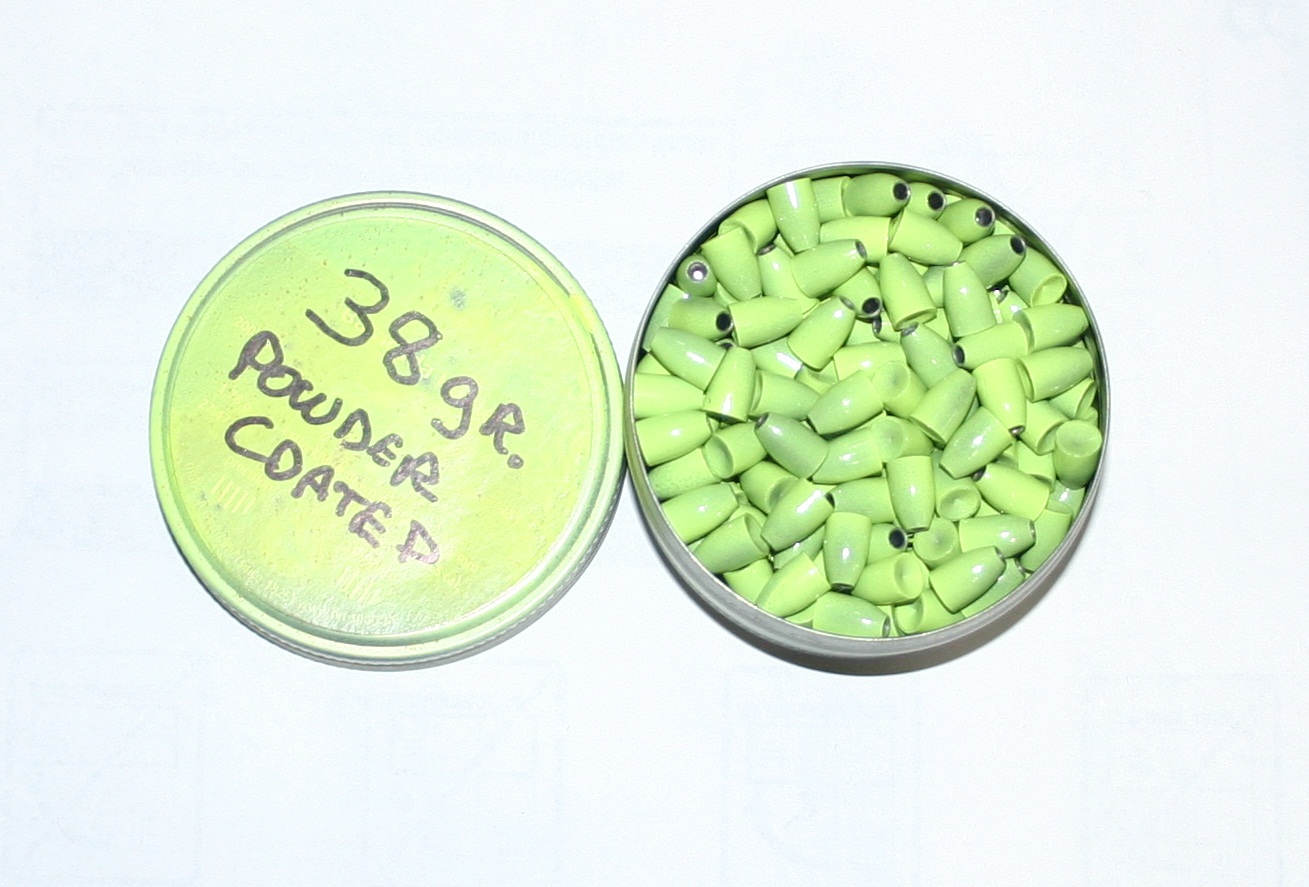

Yes Mike you are kinda correct. The industry was not looking into it but it was a side affect of us boolit caster. It is powder coat. It contains the lead and while doing so does provide a slicker less resistant surface than copper or traditional lubes allowing higher speeds to be achieved. Once again faster is not always better if you care about the object you are attempting to hit. Given the fact that air guns do not have throating issues a barrel already lasts forever and does not have to be subject to powder burners issues. I guess you could get a few extra feet per second out of a PC boolit with less air. I would feel this would work better in the big bore stuff coming out of the lesser power guns like the AEA stuff.

Long time powder coated myself, easy to clean the barrel, no increase in accuracy.

Upvote 0

I just read a report that Anschutz did a study and found for a .177 pellet 650 FPS was the optimum speed for best accuracy , this was for the early SSP competition Olympic shooting . So maybe only for 10 yards ?Faster isn’t necessarily better or more accurate

Upvote 0

I've tried coating and heat curing pellets (HiTek coating). No carbon build-up in barrel, but terrible accuracy/precision likely due to inconsistent coating of pellets, despite putting very thin coatings for each of 3 to 4 coats.Long time powder coated myself, easy to clean the barrel, no increase in accuracy.

View attachment 440457

Upvote 0

How about u lower ur air expenditure still keeping your previous velocities! Won't that be a plus point, theoretically speakingFaster isn’t necessarily better or more accurate

Upvote 0

I think hand coating won't tell u the exact benifit if any, may be some who have access to precision industry can make such coating with exact thickness and weight all around and tell it good or badLong time powder coated myself, easy to clean the barrel, no increase in accuracy.

View attachment 440457

Upvote 0

I had believed that earlier, but my neighbour who is a regional championship proves me wrong by using Brokock bantam .177 in Gsmith slug for 50 metres in near 900fps, maybe he is real skills with his guns tuning or he is one lucky with his barrels conditionI just read a report that Anschutz did a study and found for a .177 pellet 650 FPS was the optimum speed for best accuracy , this was for the early SSP competition Olympic shooting . So maybe only for 10 yards ?

Upvote 0

They were called Nylock… spelling might be wrong. Assuming from the name nylon, in some form, was the coating. I might still have a couple around somewhere.Pure Teflon is way too soft ! It's VERY likely to deform to a blob when the air pressure hits it .

Now, as you say, maybe a thin coating of Teflon on a standard shaped, lead pellet, that might be something to study.

I remember many years ago, the firearm industry was looking at plastic coated bullets. Don't recall the exact type of plastic/polymer that they used but they were available for purchase for a few years. Helped lower lead fouling, and helped the bullet go a little faster down the barrel.

I never tried any.

Mike

I’m not 100% sure, but I think their demise was because they were supposed to be able to penetrate body armor.

Upvote 0

I remember those too.They were called Nylock… spelling might be wrong. Assuming from the name nylon, in some form, was the coating. I might still have a couple around somewhere.

I’m not 100% sure, but I think their demise was because they were supposed to be able to penetrate body armor.

I loaded some. At 3/8 steel gongs at 100 yards the target barely moved and it drilled perfect .30 caliber holes.

Between that and the fear of fouling, I stopped using them. Still have them somewhere.

Question for the pellet coaters: Do you notice any loss of expansion with the coated pellets?

thanks

Doc

Upvote 0

A Teflon infused powder coat works on slugs. Never tried it on pellets.

Just add solvent and spray your slugs one coat and cure them in a small toaster oven.

Makes them .001" larger in diameter. An even coat produces a very accurate round.

Doesn't completely stop barrel fowling or increase velocity in my barrels.

But, with the bright color they can be seen in the air as they reach POI at long range. And expansion isn't affected.

Just add solvent and spray your slugs one coat and cure them in a small toaster oven.

Makes them .001" larger in diameter. An even coat produces a very accurate round.

Doesn't completely stop barrel fowling or increase velocity in my barrels.

But, with the bright color they can be seen in the air as they reach POI at long range. And expansion isn't affected.

Upvote 0

Pellet not slug , slugs are a whole different animal . post # 14I had believed that earlier, but my neighbour who is a regional championship proves me wrong by using Brokock bantam .177 in Gsmith slug for 50 metres in near 900fps, maybe he is real skills with his guns tuning or he is one lucky with his barrels condition

Upvote 0

I think hand coating won't tell u the exact benifit if any, may be some who have access to precision industry can make such coating with exact thickness and weight all around and tell it good or bad

I have a sprayer and a turntable for exact coatings but that didn't change anything and that is aloo why the ammo industry also abandoned the method, it just didn't do much but keep your fingers clean.

Upvote 0

I think those are also called anti vandal paints, in that they should be easier to clean if a grafitti punk have been by.A Teflon infused powder coat

I have limited experience spraying these myself but i did find them not charging / sticking as well as traditional polyester powder.

I also made my own mouse mat with this kind of powder, with fresh mouse feet on the mouse it was slick as snot on a door knob.

Spraying powder, while it is electro static you will get more paint on the surface facing the gun, and even working a booth with 4 guns on either side of the conveyor, it was still you and your hand gun that had to make sure all the hard to reach places was done up right.

Upvote 0