55 tins of pellets and the Yong Heng started to struggle to get over 200 bar. Lower piston looked great, but the high pressure piston rings apparently were worn down too much. Piston bores looked great. Ordered a new piston and rod assembly for $25.00 from Ali. Took about 3 weeks to arrive.

Pulled the complete top end off in one piece and saw there was some debris in the bottom of the crank case.Took off the front cover and rinsed it out with Brakleen, Watch out for that front cover preformed gasket/baffle. It shrinks and was difficult to get back into it's groove. Yep, assembled and it felt great,running in the four bolts......but it had partially slipped at the top groove and allowed a small oil leak. Off it came and what little it ran under no load, there was some new metal in the oil. Rinsed it out again and pulled and stretched the gasket(hot water)....but it just returns to it's shrunken state Clamped it in place dry for a couple hours and it stayed put long enuf to assemble it. Ran it several times with no load and now works good again. No leaks and dead heads quickly to over 300 bar.

Clamped it in place dry for a couple hours and it stayed put long enuf to assemble it. Ran it several times with no load and now works good again. No leaks and dead heads quickly to over 300 bar.

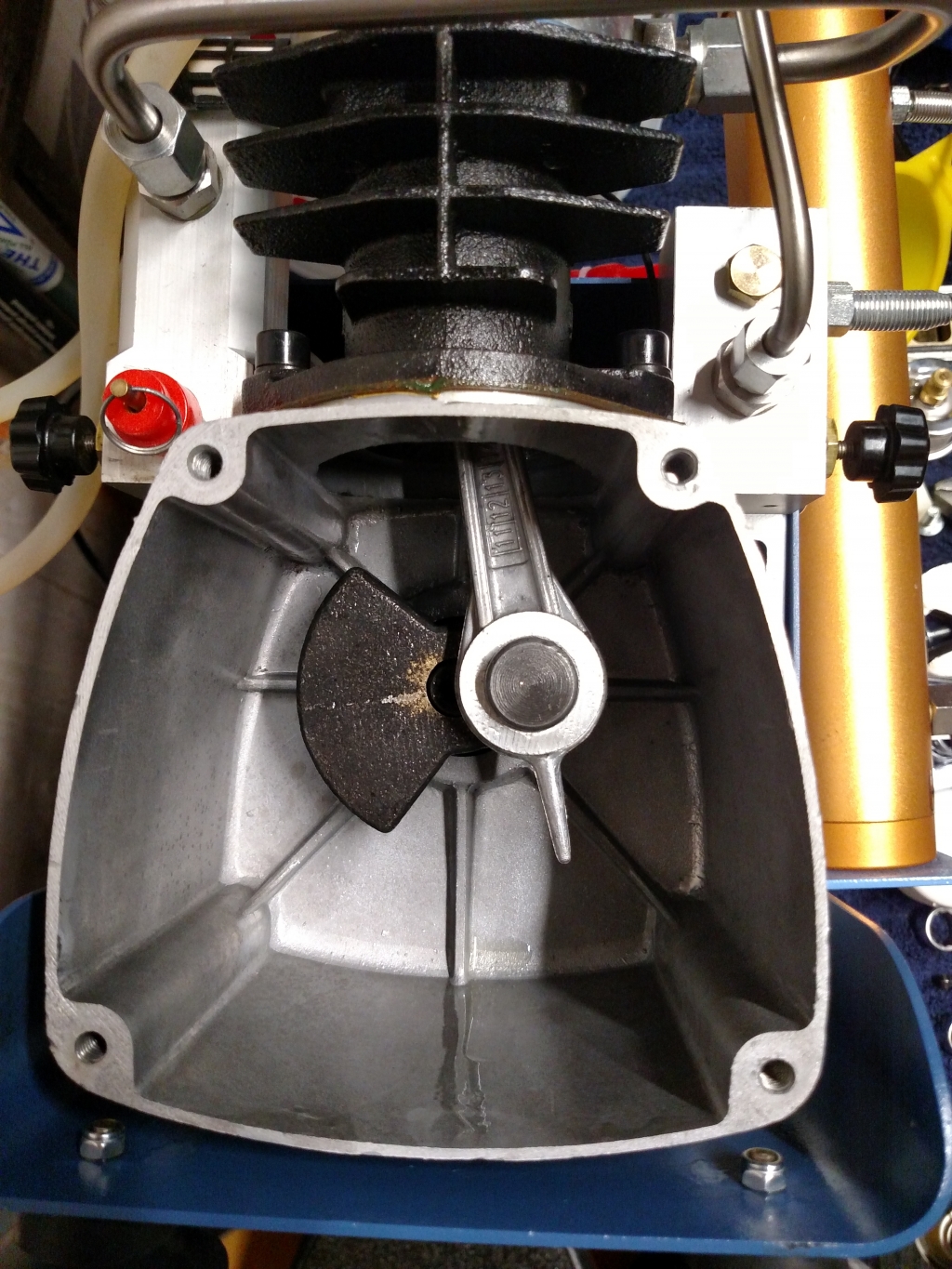

Cover removed to clean out wear residue.

Dry gasket clamped in place at the corners

Gasket stayed this time. Grease wouldn't hold it

Top piston ring wear.

Bottom piston rings are barely worn.

Pulled the complete top end off in one piece and saw there was some debris in the bottom of the crank case.Took off the front cover and rinsed it out with Brakleen, Watch out for that front cover preformed gasket/baffle. It shrinks and was difficult to get back into it's groove. Yep, assembled and it felt great,running in the four bolts......but it had partially slipped at the top groove and allowed a small oil leak. Off it came and what little it ran under no load, there was some new metal in the oil. Rinsed it out again and pulled and stretched the gasket(hot water)....but it just returns to it's shrunken state

Cover removed to clean out wear residue.

Dry gasket clamped in place at the corners

Gasket stayed this time. Grease wouldn't hold it

Top piston ring wear.

Bottom piston rings are barely worn.