I went to toms website and downloaded the oring sheet with all the sizes and figured since it took me a few minutes to search everything out I would post it here.

Will someone that is familiar orings and the sizes please double check and confirm I'm not ordering the wrong stuff?

If everything checks out then others can use the links to quickly make their own oring kits for their evols.

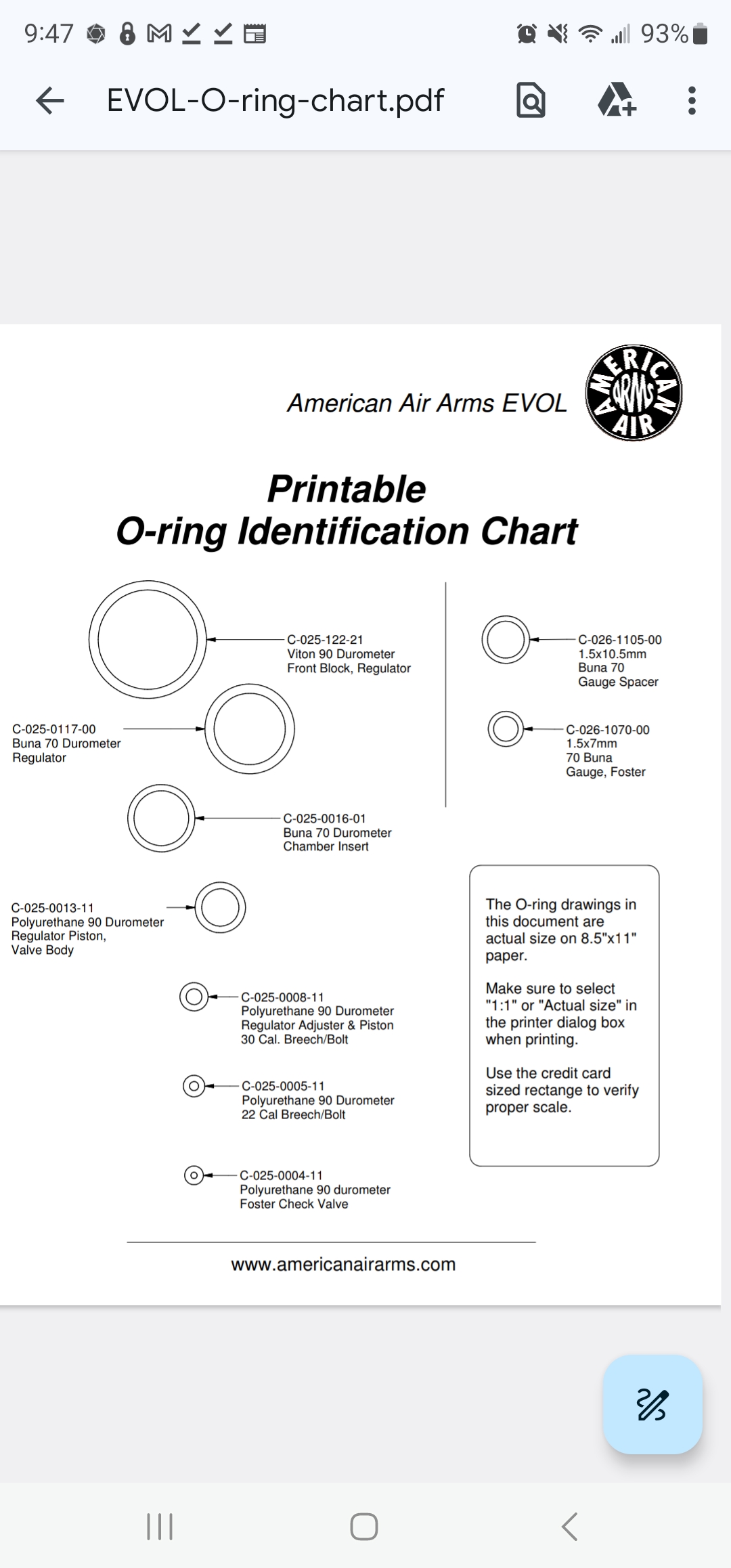

1.5mm X 7mm (NBR) Buna-N 70 Duro Metric O-Ring: C-026-1070-00 1.5x7mm 70 Buna Gauge, Foster

1.5mm X 10.5mm (NBR) Buna-N 70 Duro Metric O-Ring: C-026-1105-00 1.5x10.5mm Buna 70 Gauge Space

AS568-005 U90 EU Polyether Urethane 90 Duro O-Ring: C-025-0005-11 Polyurethane 90 Durometer 22 Cal Breech/Bolt

AS568-008 U90 EU Polyether Urethane 90 Duro O-Ring: C-025-0008-11 Polyurethane 90 Durometer Regulator Adjuster & Piston 30 Cal. Breech/Bolt

AS568-004 U90 EU Polyether Urethane 90 Duro O-Ring: C-025-0004-11 Polyurethane 90 durometer Foster Check Valve

AS568-013 U90 EU Polyether Urethane 90 Duro O-Ring: C-025-0013-11 Polyurethane 90 Durometer Regulator Piston, Valve Body

AS568-016 B70 (NBR) Buna-N Nitrile 70 Duro O-Ring: C-025-0016-01 Buna 70 Durometer

Chamber Insert

AS568-122 V90 Fluorocarbon FKM 90 Duro O-Rings: C-025-122-21 Viton 90 Durometer Front Block, Regulator

C-025-122-21

Polyurethane Durometer 90

Front Block, Regulator

(SAME SIZE AS ABOVE BUT THIS IS ANOTHER OPTION BASED ON @Bladebum on ham RECOMMENDATION) if you are having issues with the Viton 90 Durometer then you might want to try this out.

AS568-117 B70 (NBR) Buna-N Nitrile 70 Duro O-Ring: C-025-0117-00 Buna 70 Durometer Regulator

Will someone that is familiar orings and the sizes please double check and confirm I'm not ordering the wrong stuff?

If everything checks out then others can use the links to quickly make their own oring kits for their evols.

1.5mm X 7mm (NBR) Buna-N 70 Duro Metric O-Ring: C-026-1070-00 1.5x7mm 70 Buna Gauge, Foster

1.5mm X 7mm (NBR) Buna-N 70 Duro Metric O-Ring [N1.50X007] : The O-Ring Store LLC, We make getting O-Rings easy!

The O-Ring Store LLC 1.5mm X 7mm (NBR) Buna-N 70 Duro Metric O-Ring [N1.50X007] - Buna-N Nitrile (NBR) Metric O-Rings – 70 Durometer The O-Ring Store LLC provides high-quality Buna-N Nitrile (NBR) Metric O-Rings, engineered for superior sealing performance across industrial, automotive, and...

www.theoringstore.com

1.5mm X 10.5mm (NBR) Buna-N 70 Duro Metric O-Ring: C-026-1105-00 1.5x10.5mm Buna 70 Gauge Space

1.5mm X 10.5mm (NBR) Buna-N 70 Duro Metric O-Ring [N1.50X010.5] : The O-Ring Store LLC, We make getting O-Rings easy!

The O-Ring Store LLC 1.5mm X 10.5mm (NBR) Buna-N 70 Duro Metric O-Ring [N1.50X010.5] - Buna-N Nitrile (NBR) Metric O-Rings – 70 Durometer The O-Ring Store LLC provides high-quality Buna-N Nitrile (NBR) Metric O-Rings, engineered for superior sealing performance across industrial, automotive, and...

www.theoringstore.com

AS568-005 U90 EU Polyether Urethane 90 Duro O-Ring: C-025-0005-11 Polyurethane 90 Durometer 22 Cal Breech/Bolt

AS568-005 U90 EU Polyether Urethane 90 Duro O-Ring [U90005] : The O-Ring Store LLC, We make getting O-Rings easy!

The O-Ring Store LLC AS568-005 U90 EU Polyether Urethane 90 Duro O-Ring [U90005] - 3/32"ID X 7/32"OD X 1/16"CS Polyurethane: EU Polyether Urethane General Purpose EU Polyurethane rubber is notable for its combination of hardness with elasticity, outstanding abrasion resistance and tear strength...

www.theoringstore.com

AS568-008 U90 EU Polyether Urethane 90 Duro O-Ring: C-025-0008-11 Polyurethane 90 Durometer Regulator Adjuster & Piston 30 Cal. Breech/Bolt

AS568-008 U90 EU Polyether Urethane 90 Duro O-Ring [U90008] : The O-Ring Store LLC, We make getting O-Rings easy!

The O-Ring Store LLC AS568-008 U90 EU Polyether Urethane 90 Duro O-Ring [U90008] - 3/16"ID X 5/16"OD X 1/16"CS Polyurethane: EU Polyether Urethane General Purpose EU Polyurethane rubber is notable for its combination of hardness with elasticity, outstanding abrasion resistance and tear strength...

www.theoringstore.com

AS568-004 U90 EU Polyether Urethane 90 Duro O-Ring: C-025-0004-11 Polyurethane 90 durometer Foster Check Valve

AS568-004 U90 EU Polyether Urethane 90 Duro O-Ring [U90004] : The O-Ring Store LLC, We make getting O-Rings easy!

The O-Ring Store LLC AS568-004 U90 EU Polyether Urethane 90 Duro O-Ring [U90004] - 5/64"ID X 13/64"OD X 1/16"CS Polyurethane: EU Polyether Urethane General Purpose EU Polyurethane rubber is notable for its combination of hardness with elasticity, outstanding abrasion resistance and tear...

www.theoringstore.com

AS568-013 U90 EU Polyether Urethane 90 Duro O-Ring: C-025-0013-11 Polyurethane 90 Durometer Regulator Piston, Valve Body

AS568-013 U90 EU Polyether Urethane 90 Duro O-Ring [U90013] : The O-Ring Store LLC, We make getting O-Rings easy!

The O-Ring Store LLC AS568-013 U90 EU Polyether Urethane 90 Duro O-Ring [U90013] - 7/16"ID X 9/16"OD X 1/16"CS Polyurethane: EU Polyether Urethane General Purpose EU Polyurethane rubber is notable for its combination of hardness with elasticity, outstanding abrasion resistance and tear strength...

www.theoringstore.com

AS568-016 B70 (NBR) Buna-N Nitrile 70 Duro O-Ring: C-025-0016-01 Buna 70 Durometer

Chamber Insert

AS568-016 B70 (NBR) Buna-N Nitrile 70 Duro O-Ring [B70016] : The O-Ring Store LLC, We make getting O-Rings easy!

The O-Ring Store LLC AS568-016 B70 (NBR) Buna-N Nitrile 70 Duro O-Ring [B70016] - 5/8"ID X 3/4"OD X 1/16"CS Buna-N O-Rings 70 Duro (NBR): The most commonly used elastomer for sealing products. Nitrile, also known as Buna-N or NBR, is a copolymer of Butadiene and Acrylonitirle. It has a...

www.theoringstore.com

AS568-122 V90 Fluorocarbon FKM 90 Duro O-Rings: C-025-122-21 Viton 90 Durometer Front Block, Regulator

AS568-122 V90 FKM/Viton® O-Rings – High Heat & Chemical Resistant Fluorocarbon (FKM) 90 Durometer [V90122] : The O-Ring Store LLC, We make getting O-Rings easy!

The O-Ring Store LLC AS568-122 V90 FKM/Viton® O-Rings – High Heat & Chemical Resistant Fluorocarbon (FKM) 90 Durometer [V90122] - V90 FKM/Viton® O-Rings – High Heat & Chemical Resistant Fluorocarbon (FKM) 90 Durometer Upgrade your sealing performance with our V90 FKM/Viton® O-Rings, designed for...

www.theoringstore.com

C-025-122-21

Polyurethane Durometer 90

Front Block, Regulator

(SAME SIZE AS ABOVE BUT THIS IS ANOTHER OPTION BASED ON @Bladebum on ham RECOMMENDATION) if you are having issues with the Viton 90 Durometer then you might want to try this out.

AS568-122 UC90 Cast Polyurethane 90 Duro O-Rings [UC90122] : The O-Ring Store LLC, We make getting O-Rings easy!

The O-Ring Store LLC AS568-122 UC90 Cast Polyurethane 90 Duro O-Rings [UC90122] - 1-1/16"ID X 1-1/4"OD X 3/32"CS High performance 90 Durometer Cast Polyurethane High Performance Urethane O-Ring for heavy duty applications. DISOGRIN 9251 Material with outstanding wear and tear resistance, very...

www.theoringstore.com

AS568-117 B70 (NBR) Buna-N Nitrile 70 Duro O-Ring: C-025-0117-00 Buna 70 Durometer Regulator

AS568-117 B70 (NBR) Buna-N Nitrile 70 Duro O-Ring [B70117] : The O-Ring Store LLC, We make getting O-Rings easy!

The O-Ring Store LLC AS568-117 B70 (NBR) Buna-N Nitrile 70 Duro O-Ring [B70117] - 13/16"ID X 1"OD X 3/32"CS Buna-N O-Rings 70 Duro (NBR): The most commonly used elastomer for sealing products. Nitrile, also known as Buna-N or NBR, is a copolymer of Butadiene and Acrylonitirle. It has a...

www.theoringstore.com

Last edited: