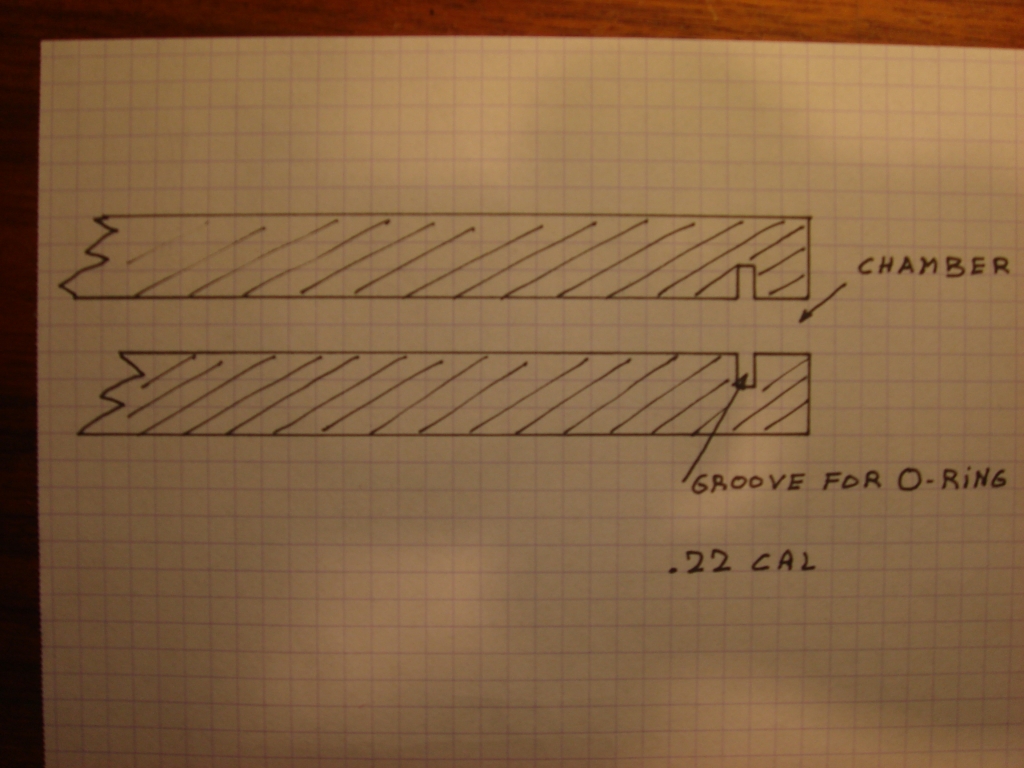

Hi , I would like to put a hexagonal Lothar Walther barrel on one of my guns ; the problem is : how to machine the tiny groove inside the chamber of the barrel for the O-ring? What kind of tool is needed to do this operation on a lathe , or on a milling machine , as the bore is only .25" in diameter? Sketch below.

Thanks

N.B. I'm not sure this is the right forum for this kind of question

Thanks

N.B. I'm not sure this is the right forum for this kind of question