After some success with casting pure lead, I just attempted to cast with 9:1 lead : linotype alloy. The difference is huge. The sprue will drop out by itself instead of sticking to the spure plate like lead. However, it seems that the metal is a LOT more brittle as the sprues would break some times when it hit the steel tray for collecting them. Is that normal ?

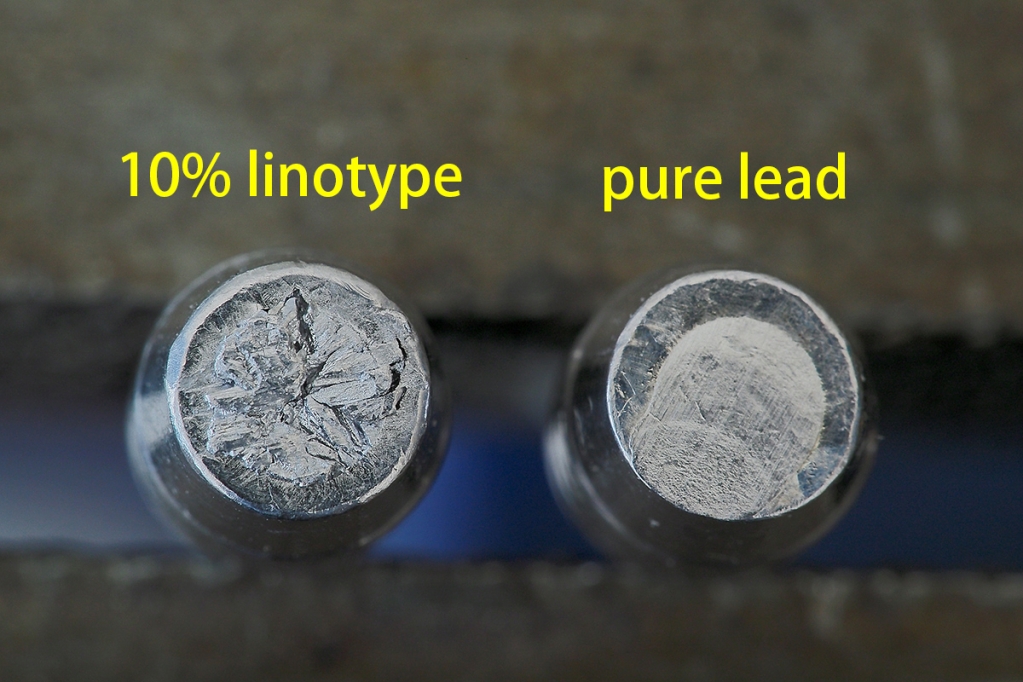

The most annoying thing is that I can no longer get a smooth cut. With lead, the cut is very smooth as can be seen in the photo below. With alloy, there a a lot of cracks in the cut like what's seen when a piece of metal is repetitively bent and ultimately breaks because of fatigue. I got some metal sticking above the cutting plane causing the magazine to be jammed some time. The length of the slug is just equal to that of the magazine so there is very little tolerance. May I have some advices on how to get a smoother cut pls ? Is it possible that I did not get linotype but some other kinds of metals ? ? Thanks in advance.

The most annoying thing is that I can no longer get a smooth cut. With lead, the cut is very smooth as can be seen in the photo below. With alloy, there a a lot of cracks in the cut like what's seen when a piece of metal is repetitively bent and ultimately breaks because of fatigue. I got some metal sticking above the cutting plane causing the magazine to be jammed some time. The length of the slug is just equal to that of the magazine so there is very little tolerance. May I have some advices on how to get a smoother cut pls ? Is it possible that I did not get linotype but some other kinds of metals ? ? Thanks in advance.