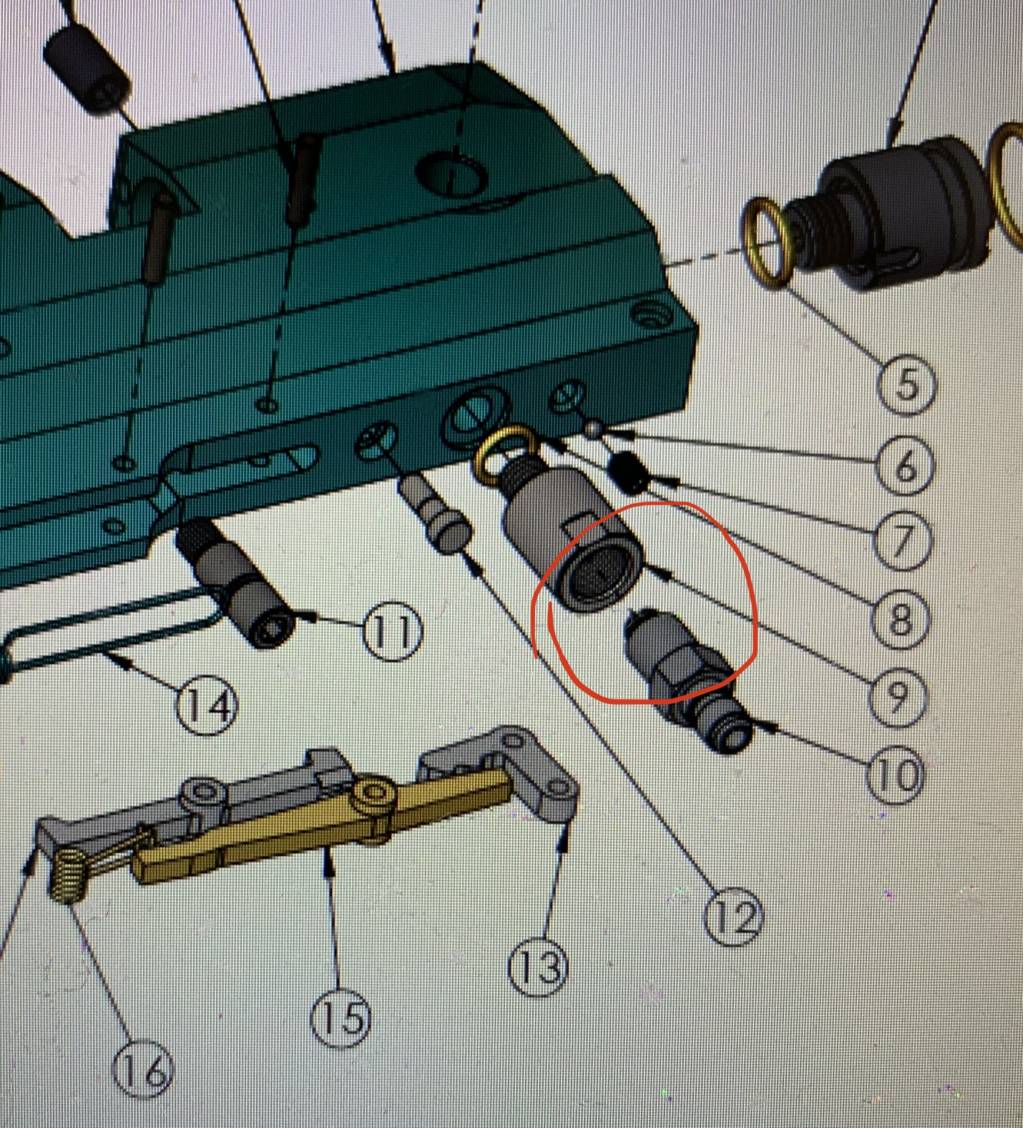

I’ve identified the source of the leak. The fill nipple (the lower piece with the hex shaped fitting) feels pretty snug, but I can still see threads in the gap where the bubbles are coming from. I don’t want to put too much torque on it. I’m wondering if placing an o-ring between the fill nipple and the fill nipple adapter would help. Although the schematic doesn’t call for one to be placed at the junction between these two parts.

I’ll try removing the nipple once more to see if I left any Teflon tape in the threads or cross threaded it when I put it back in last time. I have to get to the bottom of this leak.

I’ll try removing the nipple once more to see if I left any Teflon tape in the threads or cross threaded it when I put it back in last time. I have to get to the bottom of this leak.

Upvote 0