You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

New Yong Heng Compressor Air Leaks

- Thread starter Airslave

- Start date

Airslave,

I got my Yong Heng from best-homepro, too. He's in China but has warehouses in GA, CA, NY and New Jersey. Mine came from the NY warehouse, according to label.

My only change from your procedures is that all my pressure relief screws are open at start-up, this includes copper-colored water separator and both Yong Heng screws. Don't know how critical that is, it's just that I'm assured, following this practice, that the compressor starts as free and as clear, as possible.

Hope everything works out for you, WM

I got my Yong Heng from best-homepro, too. He's in China but has warehouses in GA, CA, NY and New Jersey. Mine came from the NY warehouse, according to label.

My only change from your procedures is that all my pressure relief screws are open at start-up, this includes copper-colored water separator and both Yong Heng screws. Don't know how critical that is, it's just that I'm assured, following this practice, that the compressor starts as free and as clear, as possible.

Hope everything works out for you, WM

Upvote 0

Another likely leak possibility is the hose to bleed block union. There should also be a white nylon washer between the socket and the threaded end of the hose.

Upvote 0

I highly doubt that there would be Teflon tape on the gauge from the factory, it sounds like somebody had their hands on the compressor before you got it. Did you buy it as new?, if so I would ask for a replacement before I went any further.

Upvote 0

I open both bleed screws to start and stop to relieve pressure on the compressor.

I removed the fill hose and checked the filter for any obstruction and it was clear.

I want to but I'm not, remove the second stage to first stage pipe and see if I'm getting any pressure. Don't want to do anything to void the warranty.

When I start the compressor and close the bleed valves I can hear the compressor put under load but it won't pump pressure to the air rifle. I know it takes time to build up pressure before the gauge starts to move but I waited 3 minutes and should have seen something.

If todays tests don't get me any closer to finding the problem I'll have to contact the seller. I had heard he is a reputable seller and is a dealer for YH.

Thanks everyone for your help.

I removed the fill hose and checked the filter for any obstruction and it was clear.

I want to but I'm not, remove the second stage to first stage pipe and see if I'm getting any pressure. Don't want to do anything to void the warranty.

When I start the compressor and close the bleed valves I can hear the compressor put under load but it won't pump pressure to the air rifle. I know it takes time to build up pressure before the gauge starts to move but I waited 3 minutes and should have seen something.

If todays tests don't get me any closer to finding the problem I'll have to contact the seller. I had heard he is a reputable seller and is a dealer for YH.

Thanks everyone for your help.

Upvote 0

https://youtu.be/YjsBcKSVeGk

Perhaps this video may help, I recall someone having problems building pressure, and a check valve was the culprit.

Perhaps this video may help, I recall someone having problems building pressure, and a check valve was the culprit.

Upvote 0

Scotty1,

I just saw his video(great vid) and the check valve.

The output fill hose didn't have a white washer so I put one in. Also changed the burst disk even though it was good.

The compressor wasn't building pressure at all bit now it go to 500psi very quickly so something changed.

I didn't want to remove the stainless piping but since you mentioned it and the video I'll do that.

Appreciate all your help.

I'm going to write the seller just to let him know I'm having trouble but not till I check the check valves.

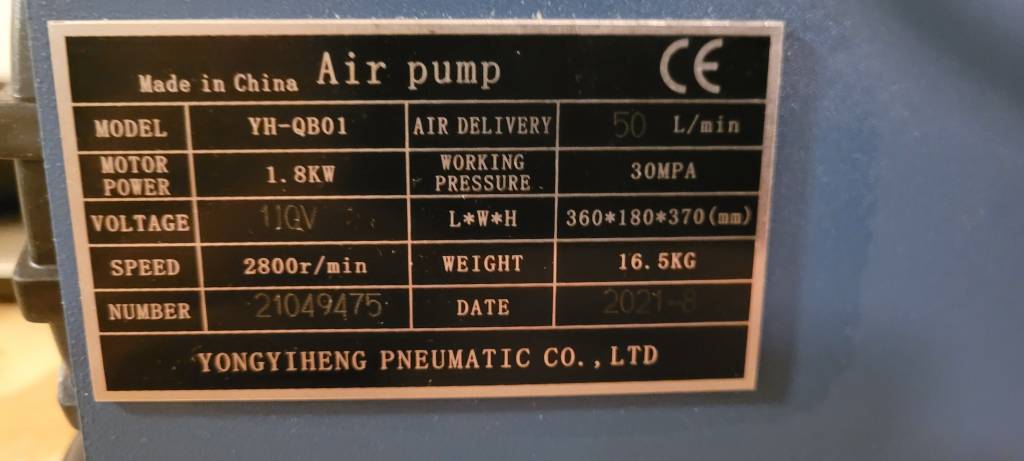

I was asked to provide a some pictures so here is my id plate ---

I just saw his video(great vid) and the check valve.

The output fill hose didn't have a white washer so I put one in. Also changed the burst disk even though it was good.

The compressor wasn't building pressure at all bit now it go to 500psi very quickly so something changed.

I didn't want to remove the stainless piping but since you mentioned it and the video I'll do that.

Appreciate all your help.

I'm going to write the seller just to let him know I'm having trouble but not till I check the check valves.

I was asked to provide a some pictures so here is my id plate ---

Upvote 0

Airslave,

If compressor seems to load after closing of pressure relief screws, but zero air comes from hose, what Eaglebeak said jogged my memory. A new Yong Heng owner had similar problem only to discover he'd tightened hose too tight to compressor squashing the white "donut" plastic washer so much that the center hole closed. Just a thought.

Also, did that wonky tape around gauge threads look like it had been installed or maybe just the remains from something hung there like an advertising brochure?

My YH takes some time to fill up all my filters, then match pressure in the gun before anything shows up on gun gauge. I just keep an eye on the head temperature display to make sure nothing overheats. WM

If compressor seems to load after closing of pressure relief screws, but zero air comes from hose, what Eaglebeak said jogged my memory. A new Yong Heng owner had similar problem only to discover he'd tightened hose too tight to compressor squashing the white "donut" plastic washer so much that the center hole closed. Just a thought.

Also, did that wonky tape around gauge threads look like it had been installed or maybe just the remains from something hung there like an advertising brochure?

My YH takes some time to fill up all my filters, then match pressure in the gun before anything shows up on gun gauge. I just keep an eye on the head temperature display to make sure nothing overheats. WM

Upvote 0

Same compressor plate as mine, that's a Yong Heng. If you've got pressure, will a dead head test work now? If not, I'd try spraying soapy water while operating. I did the soapy water test, even though everything seemed OK, only to find I wasn't tightening down one of my pressure relief screws enough. WM

Upvote 0

Thanks.

There is air coming out of the hose. How much I don't know but when connected to the rifle it will only go to 500psi.

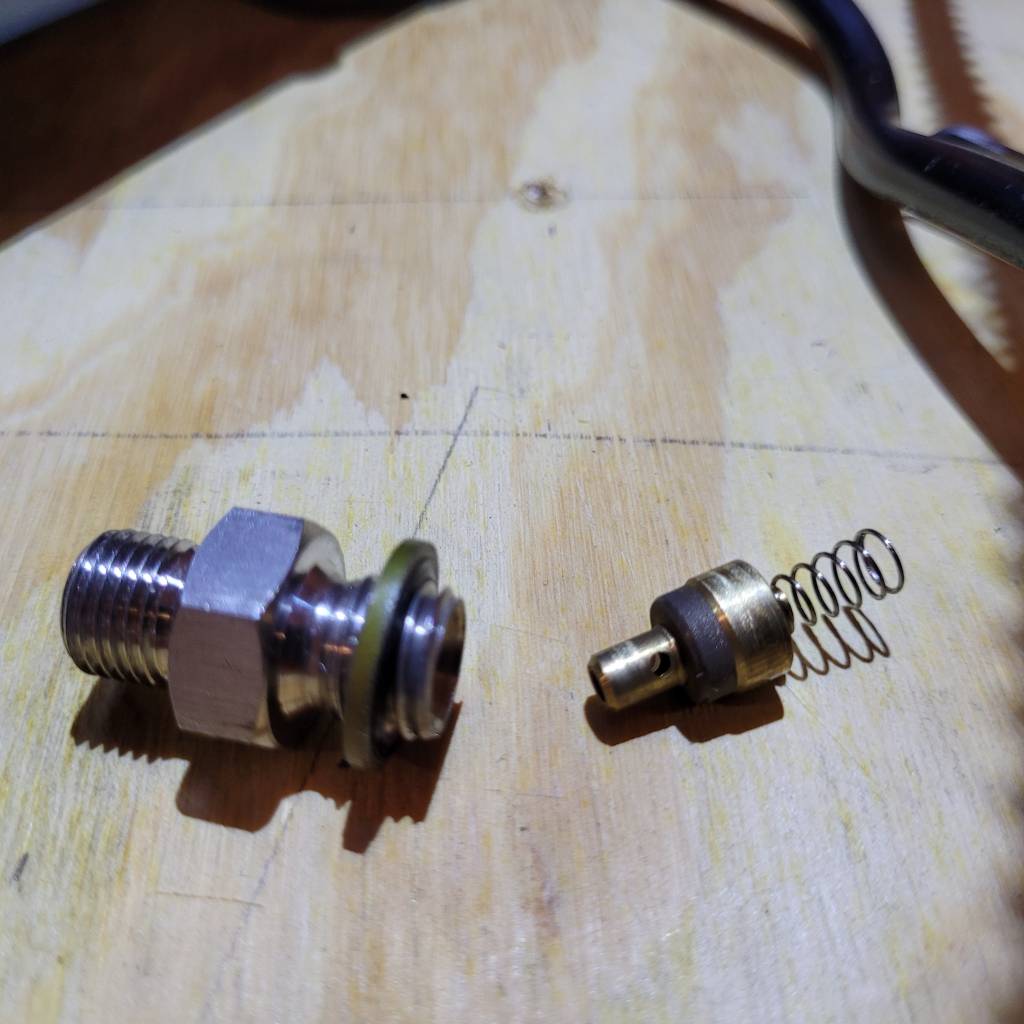

Here are the pictures of the valves.... and that was fun...it looks like they used every size nut ever made???

I don't see anything wrong. Maybe the gasket on the left picture is a little worn.

I looked into the holes where the pipes went and it was clear. I blew thru the pipes and they were clear.

Any ideas cause I'm clueless. I'll have to look at the complete series from the video. Maybe I'll learn something.

I wonder what the first stage pressure is? Just incase the the second stage is not stepping up the pressure. Just wondering

I hate to keep bothering you all so a big thanks for your help.

There is air coming out of the hose. How much I don't know but when connected to the rifle it will only go to 500psi.

Here are the pictures of the valves.... and that was fun...it looks like they used every size nut ever made???

I don't see anything wrong. Maybe the gasket on the left picture is a little worn.

I looked into the holes where the pipes went and it was clear. I blew thru the pipes and they were clear.

Any ideas cause I'm clueless. I'll have to look at the complete series from the video. Maybe I'll learn something.

I wonder what the first stage pressure is? Just incase the the second stage is not stepping up the pressure. Just wondering

I hate to keep bothering you all so a big thanks for your help.

Upvote 0

They do seem okay, but can’t see the sealing surface well in the 2nd pic, and that bit of debris on the table didn’t come from that valve, did it? Did you get the parts bag with it? If so maybe replace what you can while apart, particularly the dowty seals. If you can get it to hold pressure with a deadhead, soapy water may be more revealing, I have found slight leaks this way, even with it running. I understand your desire to get it running and would do the same personally, even if the vendor should replace it…I can’t keep myself from trying to find out why, and making a repair myself. Boon or bane.

Upvote 0

Your right. Got it apart so might as well put new seals on.

Nothing from the seals. Must have been from the gauge when I replaced the tape with the plastic seal.

One thing I forgot to do... while I had 500psi I should have gone straight to deadhead and did the soapy test. When I get it back together and it pressurizes to anything I'll do that.

Yep... I like a challenge but not being familiar with it's frustrating.

Once again thank you.

Nothing from the seals. Must have been from the gauge when I replaced the tape with the plastic seal.

One thing I forgot to do... while I had 500psi I should have gone straight to deadhead and did the soapy test. When I get it back together and it pressurizes to anything I'll do that.

Yep... I like a challenge but not being familiar with it's frustrating.

Once again thank you.

Upvote 0

Airslave,

From pictures, everything looks new, so possible you might have a "lemon." Bio has said many times that Chinese quality control is not the best, of his two compressors, one was good, the other, not. I agree with Scotty, a soapy water leak test, with compressor running or shut down "dead-headed" is the best way to find an external leak. You said you can hear the leak, so that seems to indicate external. I'd soak the thing, including filters, with a spray bottle of soapy water until I found the leak. Using the dead-head will eliminate any possible gun or fill probe leaks, so I'd use it. The two aluminum blocks have vent holes on the bottom for air to escape from pressure release screws, so spray under there, too. Keep us posted, WM

From pictures, everything looks new, so possible you might have a "lemon." Bio has said many times that Chinese quality control is not the best, of his two compressors, one was good, the other, not. I agree with Scotty, a soapy water leak test, with compressor running or shut down "dead-headed" is the best way to find an external leak. You said you can hear the leak, so that seems to indicate external. I'd soak the thing, including filters, with a spray bottle of soapy water until I found the leak. Using the dead-head will eliminate any possible gun or fill probe leaks, so I'd use it. The two aluminum blocks have vent holes on the bottom for air to escape from pressure release screws, so spray under there, too. Keep us posted, WM

Upvote 0

Airslave, you are now in good company. I went to fill my bottle, not realizing I have my check in the fill hose, air now leaks out the crankcase and it won’t build pressure. I hope your compressor day works out better than mine. I did get the green light to order a better compressor, knowing what that means. I sure would like to be done with running on the bleeding edge for every fill….

Upvote 0

I highly doubt that there would be Teflon tape on the gauge from the factory, it sounds like somebody had their hands on the compressor before you got it. Did you buy it as new?, if so I would ask for a replacement before I went any further.

YES THIS ^^^^^^

Upvote 0

Your right. Got it apart so might as well put new seals on.

Nothing from the seals. Must have been from the gauge when I replaced the tape with the plastic seal.

One thing I forgot to do... while I had 500psi I should have gone straight to deadhead and did the soapy test. When I get it back together and it pressurizes to anything I'll do that.

Yep... I like a challenge but not being familiar with it's frustrating.

Once again thank you.

Yup you be right it would have been good to do that test while it had pressure to find other leaks.

You got to watch the Chinese QC for sure. A missing seal here, a loose connection there and a bad o-ring in some other place can have you spinning in circles for sure.

Just get it up to whatever pressure it will build to, turn it off, and find the leaks. Each time you fix one it will build more pressure.

I wish you luck I have been where you are several times.

Eventually I always win, my Yong Heng battles cuz I never give up till I do.

Upvote 0

Remember what THEY say, tinker enough and replace parts and everything can be made to work. It's the parts thing that leads to dead ends.

Upvote 0

Scotty to hear bout yours. Think positive.. you can get a better one... which I would have no idea about.

Heavy-impact - I looked at the disk before destroying it to get it out and it didn't show any signs of tears, slits, rips or holes. Good call.

Yea - the teflon tape was a strange one. I've only found it on the gauge. Since the gauge didn't have a plastic washer I suspect they ran out and used the tape.

I looked at all the connection points and fittings and they look new so I think it's brand new.

Tomorrow after another try and still problems, I'll send the seller a it's broke message. No matter what happens I'll have a compressor on order by the end of the day. Probably a YH. Hey... how unlucky can I get.. Jan the orange air cooled one quit after 6 fillings and this one has never worked. If the third one is a bummer I'm driving to GA and personally deliver it and get a new one. Buying a compressor is not suppose to work this way???

I want to thank everyone for your input. When I get frustrated I forget to double check myself. That's why I have to walk away from it for awhile.

Heavy-impact - I looked at the disk before destroying it to get it out and it didn't show any signs of tears, slits, rips or holes. Good call.

Yea - the teflon tape was a strange one. I've only found it on the gauge. Since the gauge didn't have a plastic washer I suspect they ran out and used the tape.

I looked at all the connection points and fittings and they look new so I think it's brand new.

Tomorrow after another try and still problems, I'll send the seller a it's broke message. No matter what happens I'll have a compressor on order by the end of the day. Probably a YH. Hey... how unlucky can I get.. Jan the orange air cooled one quit after 6 fillings and this one has never worked. If the third one is a bummer I'm driving to GA and personally deliver it and get a new one. Buying a compressor is not suppose to work this way???

I want to thank everyone for your input. When I get frustrated I forget to double check myself. That's why I have to walk away from it for awhile.

Upvote 0