You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Tuning New valve for my raw 25 hm1000x

- Thread starter Airgunmann

- Start date

Well I got out and shot it this weekend performed flawless sighted it in and was shooting pop cans at 100 yards at on point I had 5 shots in a inch I was using a tripod though so the gun can definitely out shoot me put at least a 150 pellets threw it this weekend very pleased with the accuracy

Upvote 0

I just saw this Thread...

Great job on your design!!!

Everyone has their Own Secret Sauce when come to making valves for RAW and Rapid Airguns!!

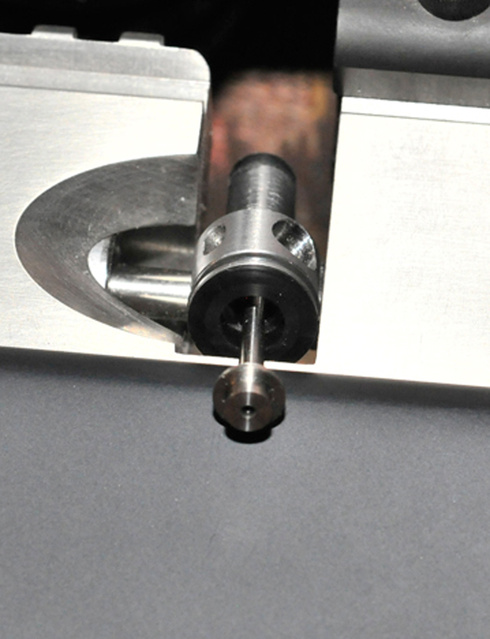

So here is my little design for my Titanium Clone Rapid..

Stainless Valve-Body, Tapered Titanium Valve-stem.

I used reamed Delrin inserts that the Valve slides on and seals on.

She gives me a good 70 fpe with JSB Beasts....

Great job on your design!!!

Everyone has their Own Secret Sauce when come to making valves for RAW and Rapid Airguns!!

So here is my little design for my Titanium Clone Rapid..

Stainless Valve-Body, Tapered Titanium Valve-stem.

I used reamed Delrin inserts that the Valve slides on and seals on.

She gives me a good 70 fpe with JSB Beasts....

Upvote 0

Yes it is!!Is that a titanium block too with a Picatinni rail

I was the administrator of the AirgunAdvice.net..

So a member on there was Chip Smith....CNC CAD designer/machinist extraordinaire. He also a member here too.

One of his first projects once he was hooked on the Rapid platform... was his Tactical Chassis for the rapid.

Then about a year later, he threw out a proposal to the member... he had some Titanium Plate stock ... should he design his own Rapid platform!!!

So he ask The members of What he should throw into his design.

His Titanium receiver would accept most standard Rapid internals, unmodified!! It has Picatinny Rail with 25 moa built-in. Also he extended the pre-chamber/plenum.

Well the rest is History...

The RAW block was based on his idea and design!

BTW..The Tactical chassis is also a custom job by Chip Smith.. the Ca Special Chip-Tac Chassis..

Upvote 0

Amazing work gentlemen! All of your fabrication skills are to be commended! Keep up the excellent work.

Upvote 0

Pretty extraordinary work by Chip

.

.

I wish they had CNC/CAD machines years ago when I took shop. I seems most anything laid out on the drafting table can be turned into reality by the machine.

I wish they had CNC/CAD machines years ago when I took shop. I seems most anything laid out on the drafting table can be turned into reality by the machine.

Upvote 0

His skill was very impressive..Pretty extraordinary work by Chip.

I wish they had CNC/CAD machines years ago when I took shop. I seems most anything laid out on the drafting table can be turned into reality by the machine.

As the Titanium receiver's specs were being iron out. He made a prototype.

Well he left out the scallop cut... Well the member of AA.net let him know..

So he ask me to take a photo and make a few measurements.

So it took him under 5 min to adjust is CAD drawing and produce the new code..

He put the prototype back into the CNC Mill.. it was Done

Upvote 0

Just a question about the tapered valve stem do I understand correctly,the valve body has the same taper as the stem so as soon as it opens any friction is gone ,when closed it’s an exact fit and seals with the delrin seat .

Upvote 0

Sounds like the derlin fits inside the valve and the stem rides in it also so I would say yeah that's how it seals. That would be my best guess if I read it correctly

Upvote 0

Here is a comparison of a stock Valve-stem to my Tapered Valve-stem.

The the machined out area of the valve-stem is never in contact with the valve-body..

Only the Face of the hat section(sealing) and the tail section(sliding) ever touches the valve-body.

My thought behind my Tapered Valve...

As the Tank pressure is falling, this allow the valve to open more..

So the taper will allow more air to flow....trying to flatten the curve...

This has work in my testing.....

But there is a tuner 220swift, ernie... is valves had and taper but reversed in orientation.

His thought is maintained Air Velocity as the tank pressure dropped!!

So Like I said... Everyone has there own Secret Sauce!!!

Upvote 0

I hadn’t thought about my first question enough obviously if the valve was tapered in the valve body the air would blow past it when open , would it be possible to use have the valve stem ride in a really close tolerance bearing bush rather than the stem be sealed with an o ring ,.

I love the engineering element of pcp guns .

My own HM1000x started as a uk spec sub 12 ,it is now uk fac spec

Changed the barrel to the 24” polygonal.22

Raw brass valve ,shortened hammer pip , new hammer spring re pressure raised , mdt buttstock,polished everything inside ,it now runs at 54 ftlb .still working on my technique but it’s doing very well

I love the engineering element of pcp guns .

My own HM1000x started as a uk spec sub 12 ,it is now uk fac spec

Changed the barrel to the 24” polygonal.22

Raw brass valve ,shortened hammer pip , new hammer spring re pressure raised , mdt buttstock,polished everything inside ,it now runs at 54 ftlb .still working on my technique but it’s doing very well

Upvote 0

Well you are almost taking my path....I hadn’t thought about my first question enough obviously if the valve was tapered in the valve body the air would blow past it when open , would it be possible to use have the valve stem ride in a really close tolerance bearing bush rather than the stem be sealed with an o ring ,.

I love the engineering element of pcp guns .

My own HM1000x started as a uk spec sub 12 ,it is now uk fac spec

Changed the barrel to the 24” polygonal.22

Raw brass valve ,shortened hammer pip , new hammer spring re pressure raised , mdt buttstock,polished everything inside ,it now runs at 54 ftlb .still working on my technique but it’s doing very well

In my first photo of the metal Valve-body with the valve-stem...

The reamed Delrin Bushing that the valve-stem's tail sliding on is a precision fit!... No O-Ring!!!

Upvote 0

Nice work makes sense

Here is a comparison of a stock Valve-stem to my Tapered Valve-stem.

The the machined out area of the valve-stem is never in contact with the valve-body..

Only the Face of the hat section(sealing) and the tail section(sliding) ever touches the valve-body.

My thought behind my Tapered Valve...

As the Tank pressure is falling, this allow the valve to open more..

So the taper will allow more air to flow....trying to flatten the curve...

This has work in my testing.....

But there is a tuner 220swift, ernie... is valves had and taper but reversed in orientation.

His thought is maintained Air Velocity as the tank pressure dropped!!

So Like I said... Everyone has there own Secret Sauce!!!

Upvote 0

Two questions.

Here is a comparison of a stock Valve-stem to my Tapered Valve-stem.

The the machined out area of the valve-stem is never in contact with the valve-body..

Only the Face of the hat section(sealing) and the tail section(sliding) ever touches the valve-body.

My thought behind my Tapered Valve...

As the Tank pressure is falling, this allow the valve to open more..

So the taper will allow more air to flow....trying to flatten the curve...

This has work in my testing.....

But there is a tuner 220swift, ernie... is valves had and taper but reversed in orientation.

His thought is maintained Air Velocity as the tank pressure dropped!!

So Like I said... Everyone has there own Secret Sauce!!!

Is your gun ungegulated?

Just to clarify, your valve seal is titanium on stainless? The delrin you mention is simply used as valve stem guide?

Upvote 0

Hi Corny,Two questions.

Is your gun ungegulated?

Just to clarify, your valve seal is titanium on stainless? The delrin you mention is simply used as valve stem guide?

First, yes my Titanium Rapid is unregulated..... in fact the Titanium tube screws directly into the receiver...Max airflow.

Second the valve body is stainless. I bushed the nose with a Delrin insert, reamed and machine the face.

This is for the Titanium valve-stem to seal on.

hth,

Stuart

Last edited:

Upvote 0

That’s really nice.

Any reasoning behind the titanium/stainless matchup?

Why not go with a stainless valve stem? Or is it difficult the create a seal with stainless on stainless?

Any reasoning behind the titanium/stainless matchup?

Why not go with a stainless valve stem? Or is it difficult the create a seal with stainless on stainless?

Upvote 0