some tools coming in to do some home tune,

on the hw98.

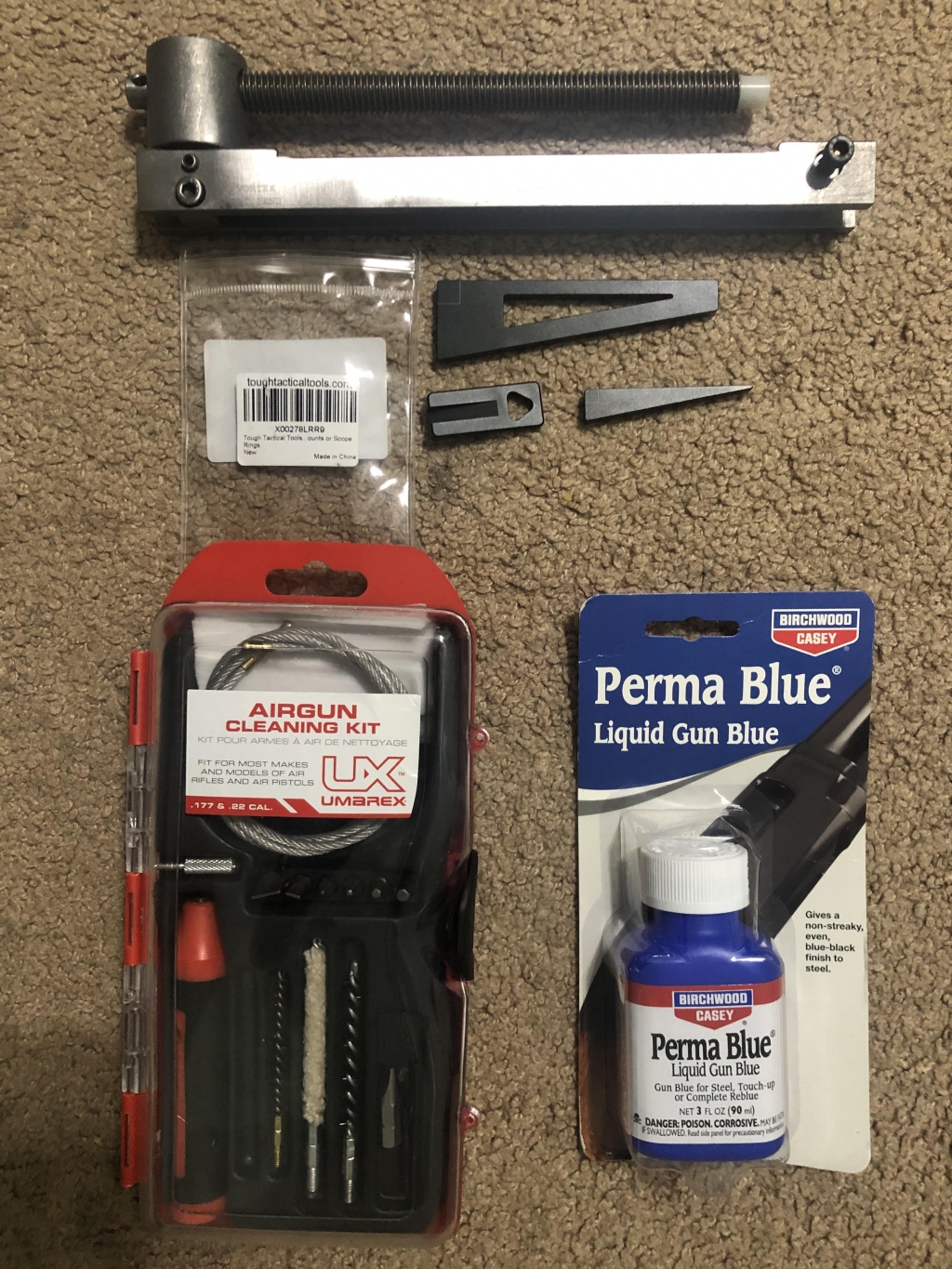

scope leveling tool to help in stall new Aztec scope, spring compressor to aid in stalling TBT pro tuning kit, v Mach seal, polish piston, and do some de burr ng . Some blueing to re blue where I cut the barrel weight down to install a moderator. Cleaning kit for general maintenance.

on the hw98.

scope leveling tool to help in stall new Aztec scope, spring compressor to aid in stalling TBT pro tuning kit, v Mach seal, polish piston, and do some de burr ng . Some blueing to re blue where I cut the barrel weight down to install a moderator. Cleaning kit for general maintenance.