You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

New SPA Artemis PP750

- Thread starter RJGTA

- Start date

If someone who owns a bipod rail for their pp700 and owns a pp750 can chime in....

Are the airtubes the same?

If so,

We may have options.

https://www.ebay.com/itm/airmax-PP700-mk2-artemis-rail-system-/184101811511

Or

Are the airtubes the same?

If so,

We may have options.

https://www.ebay.com/itm/airmax-PP700-mk2-artemis-rail-system-/184101811511

Or

Upvote 0

@wesbob

If Wes knows.

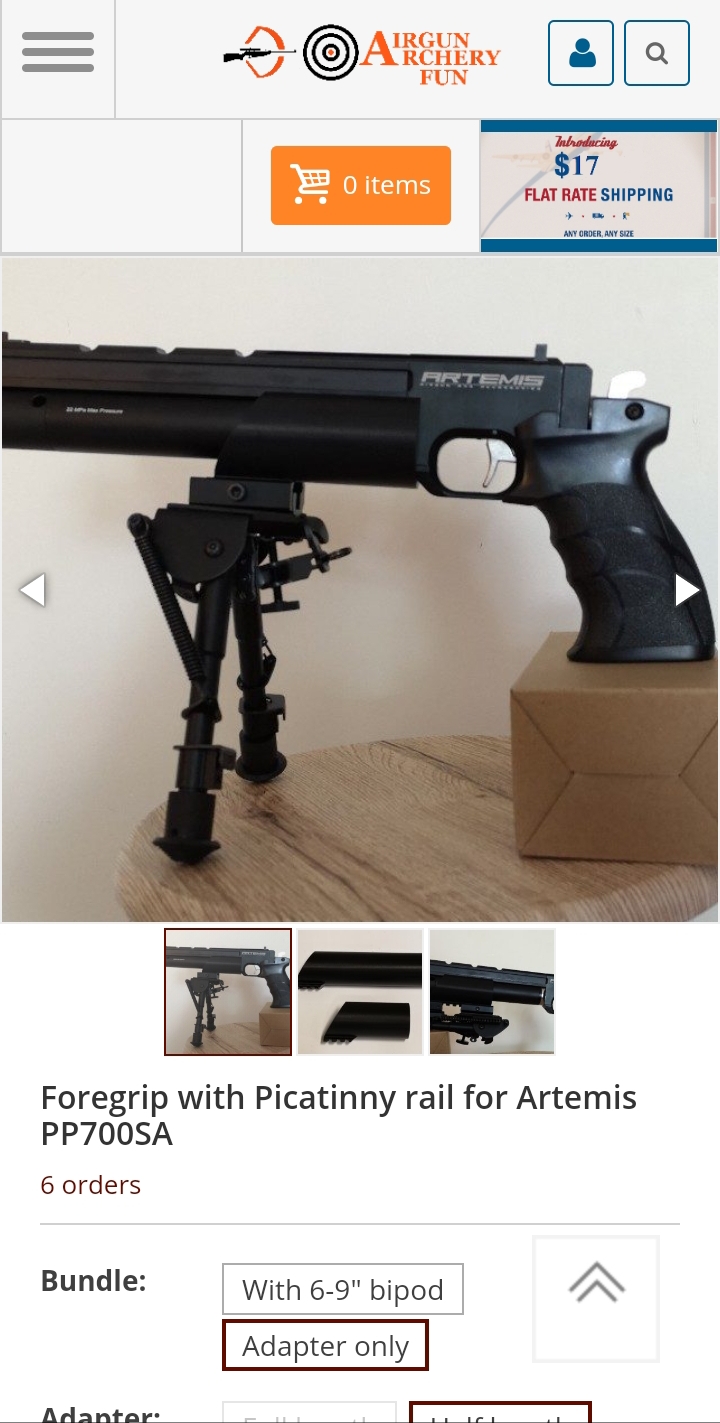

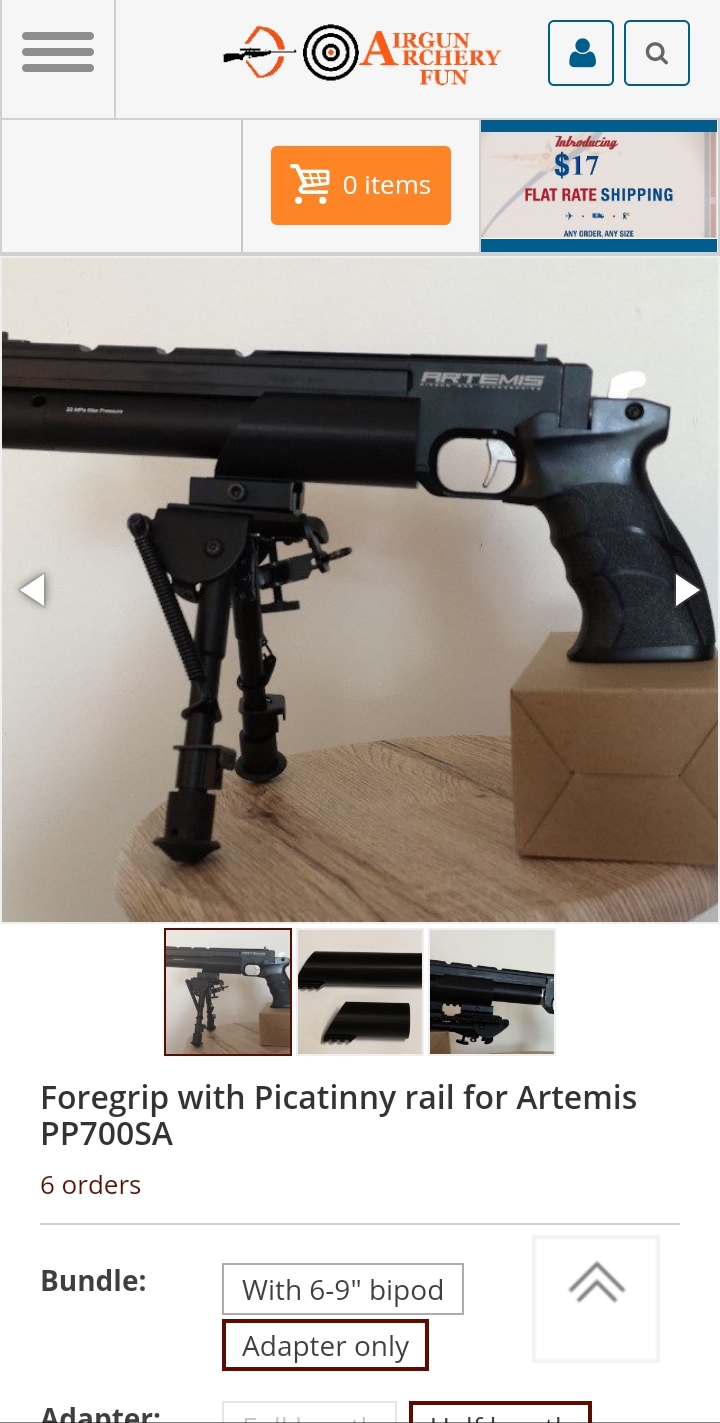

There may be other options if same size tube as pp700sa

https://airgunarcheryfun.ca/foregrip-with-picatinny-rail-for-artemis-pp700sa/

If Wes knows.

There may be other options if same size tube as pp700sa

https://airgunarcheryfun.ca/foregrip-with-picatinny-rail-for-artemis-pp700sa/

Upvote 0

Really sorry for the wait on the PP750, bummer this virus slowed things down. Makes a guy anxious to get them seeing all these great posts on them!

Nothing you can do Wes! I'll subtly try to avoid this thread until they come haha. I'm sure we all have other guns to enjoy in the interim.

Thanks yep it's hard to see all the fun, but you're right there is lots of other guns on the rack for most of us.

Upvote 0

@wesbob

If Wes knows.

There may be other options if same size tube as pp700sa

https://airgunarcheryfun.ca/foregrip-with-picatinny-rail-for-artemis-pp700sa/

I'm almost positive the tube is smaller on the PP750. Almost

Upvote 0

I'm almost positive the tube is smaller on the PP750. Almost, I don't have one yet. Maybe someone with a PP700SA chime in with a measurement of its tube? I'm away from home at the moment.

Just measured, both 32mm and completely impossible to not do some double fisted posing...

Upvote 0

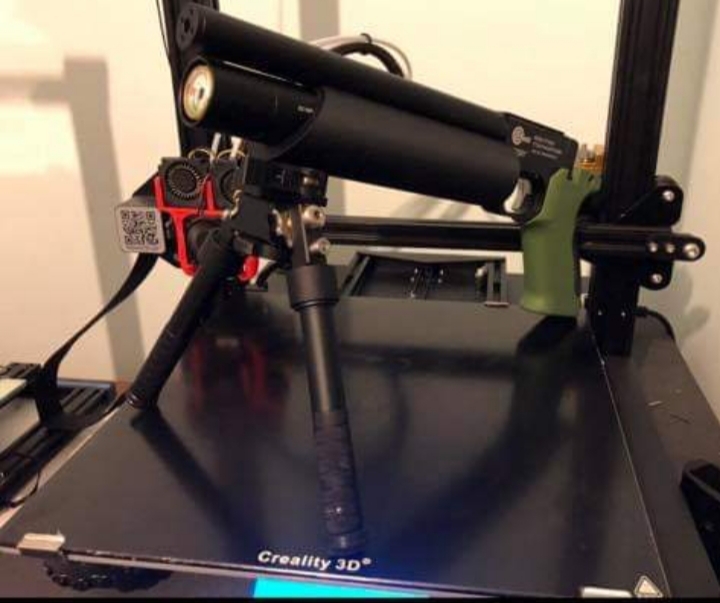

i make my own,

work fine, enough strength to stay in place, and soft enough to move along the airtube

work fine, enough strength to stay in place, and soft enough to move along the airtube

Upvote 0

some news with a 30cm barrel and other modifications, we are now around 40 joules on 10 shots

Upvote 0

I was just thinking about this last night as I was cleaning the gun down and examining the baffles at the end of the shroud. I tested with the baffles and without and with the Tanto ldc there was almost no sound difference. A little more metallic sound but not louder. Then I thought to myself it would be awesome if I could put a larger barrel on the pp750 and have it flush right to where the end of the shroud is since it is longer than the air tube. The barrel is pretty short on this gun compared to the shroud and air tube.

Upvote 0

That is incredible!

Where did you source that barrel?

I'm always wondering that when someone posts a barrel swapping thread. It's like how did you happen to have "some exotic barrel" that's already machined perfectly to fit into the gun.

Upvote 0

I was just thinking about this last night as I was cleaning the gun down and examining the baffles at the end of the shroud. I tested with the baffles and without and with the Tanto ldc there was almost no sound difference. A little more metallic sound but not louder. Then I thought to myself it would be awesome if I could put a larger barrel on the pp750 and have it flush right to where the end of the shroud is since it is longer than the air tube. The barrel is pretty short on this gun compared to the shroud and air tube.

some news with a 30cm barrel and other modifications, we are now around 40 joules on 10 shots

Very cool! That's a lot of power you are getting!

Upvote 0

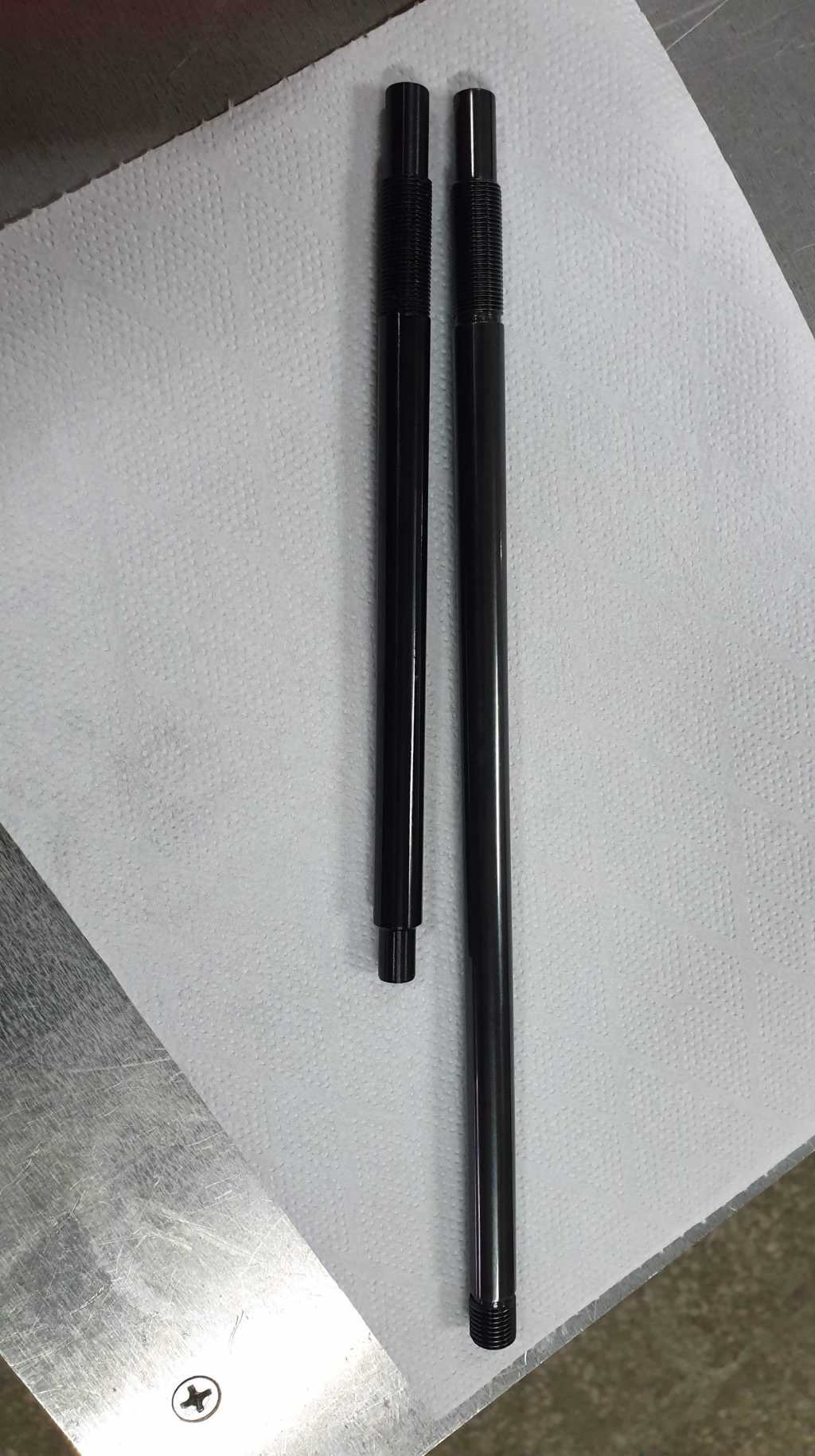

The result with a 28.5 cm long barrel, (courtesy to a my friend J)

with the original barrel we obtain around 35 joules on 10 shots,

Upvote 0

So, that's 748fps with a 25.39gr pellet for a total of 31.5FPE.

Impressive numbers!

Of course, now that the extended barrel turned the former long pistol into a short rifle — one could just get a bullpup or put a folding stock on a regular rifle....

But the tinkerers among us are probably tickled by 31.5FPE! Well done!

Matthias

Impressive numbers!

Of course, now that the extended barrel turned the former long pistol into a short rifle — one could just get a bullpup or put a folding stock on a regular rifle....

But the tinkerers among us are probably tickled by 31.5FPE! Well done!

Matthias

Upvote 0

That is incredible!

Where did you source that barrel?

it's a friend of mine who machined one for him and me

That is incredible!

Where did you source that barrel?

I'm always wondering that when someone posts a barrel swapping thread. It's like how did you happen to have "some exotic barrel" that's already machined perfectly to fit into the gun.

No exotic barrel, just a wonderfull work from my friend. it's a weirauch barrel

Upvote 0

mag_de_mars - did you increase the reg pressure at all? If so what washer config did you use?

I pulled the regulator out and there are 12 washers stacked as follows: )))((()))(((

I'd like to know what configurations would increase the pressure a bit - this is a bit of a new tuning area for me.

Edit:

Adding that I re-arranged the washers to a ))(())(())(( configuration, which according to some sites I've read, should have cut the spring rate in half - so you'd think I would've had a lot less pressure at the valve. Oddly the stock hammer spring setting still gave me the same fps (within 10 - 20 fps). I've noticed adjusting the hammer spring doesn't really do anything except blow more air - it makes me think that the spring is too strong and we're already on the 2nd hump of the reg curve.

I pulled the regulator out and there are 12 washers stacked as follows: )))((()))(((

I'd like to know what configurations would increase the pressure a bit - this is a bit of a new tuning area for me.

Edit:

Adding that I re-arranged the washers to a ))(())(())(( configuration, which according to some sites I've read, should have cut the spring rate in half - so you'd think I would've had a lot less pressure at the valve. Oddly the stock hammer spring setting still gave me the same fps (within 10 - 20 fps). I've noticed adjusting the hammer spring doesn't really do anything except blow more air - it makes me think that the spring is too strong and we're already on the 2nd hump of the reg curve.

Upvote 0

My hammer spring does about 50-70 fps range in 4 turns.

Initially in the regulator I found a silicon bead from metal filter media in the washer stack making adjustments very inconsistant. Cleaned and polished bellevilles and its very consistant with no creep. Turning the regulator screw ClockWise lowered the set point, 1/8 rotation does a lot.

Take a look at the port leading to the valve spring. That spring was covering half the 3mm port, so I opened up the port to 5mm and picked up a quite a bit.

Initially in the regulator I found a silicon bead from metal filter media in the washer stack making adjustments very inconsistant. Cleaned and polished bellevilles and its very consistant with no creep. Turning the regulator screw ClockWise lowered the set point, 1/8 rotation does a lot.

Take a look at the port leading to the valve spring. That spring was covering half the 3mm port, so I opened up the port to 5mm and picked up a quite a bit.

Upvote 0