I made several modifications on the Yong Heng:

1. I chose the 2 stage coalescing type water separator over the 3-in-one/molecular sieve type filter for 2 reasons: In a single stage separator most of the water is captured by cotton filter. Once the cotton is damped the water will be adsorbed by molecular sieve and saturate it in no time. There is no easy way to drain the water for molecular sieve except taking it out and dehydrate it. And molecular sieve can only adsorb water to approximately 14% of their own weight. If we fill up a 98cu ft tank in 50% humidity environment it contains roughly 33 gram of water that can saturate the entire tube of molecular sieve by one fill.

2. The bottom half is an CO2 laser cutter water chiller. $130 on eBay. This is the most cost efficient solution I can find for close loop water cooling. This way I can use distilled water to prevent corrosion inside the pump and not worry about contaminate the cooling water.

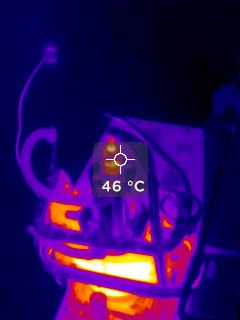

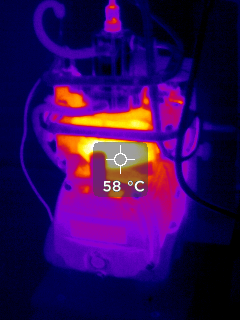

3. The second stage air tubing is another major heat source. I made a heat exchanger by bending the 1/4 copper tubing to closely match the contour of the air lines. Then wrap the air lines and copper tubing together with solid copper wires. Now the only parts that heats up more is the first stage cylinder and 60 Celsius isn't a real concern to me.

The whole set is on casters. Quite heavy with full water but I can still carry it around if I need to.

1. I chose the 2 stage coalescing type water separator over the 3-in-one/molecular sieve type filter for 2 reasons: In a single stage separator most of the water is captured by cotton filter. Once the cotton is damped the water will be adsorbed by molecular sieve and saturate it in no time. There is no easy way to drain the water for molecular sieve except taking it out and dehydrate it. And molecular sieve can only adsorb water to approximately 14% of their own weight. If we fill up a 98cu ft tank in 50% humidity environment it contains roughly 33 gram of water that can saturate the entire tube of molecular sieve by one fill.

2. The bottom half is an CO2 laser cutter water chiller. $130 on eBay. This is the most cost efficient solution I can find for close loop water cooling. This way I can use distilled water to prevent corrosion inside the pump and not worry about contaminate the cooling water.

3. The second stage air tubing is another major heat source. I made a heat exchanger by bending the 1/4 copper tubing to closely match the contour of the air lines. Then wrap the air lines and copper tubing together with solid copper wires. Now the only parts that heats up more is the first stage cylinder and 60 Celsius isn't a real concern to me.

The whole set is on casters. Quite heavy with full water but I can still carry it around if I need to.