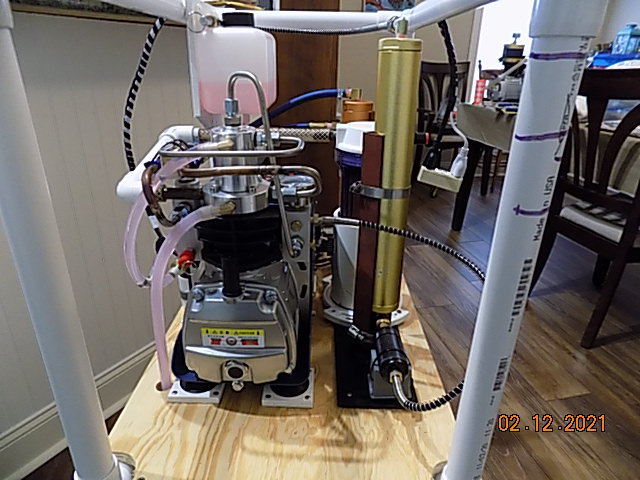

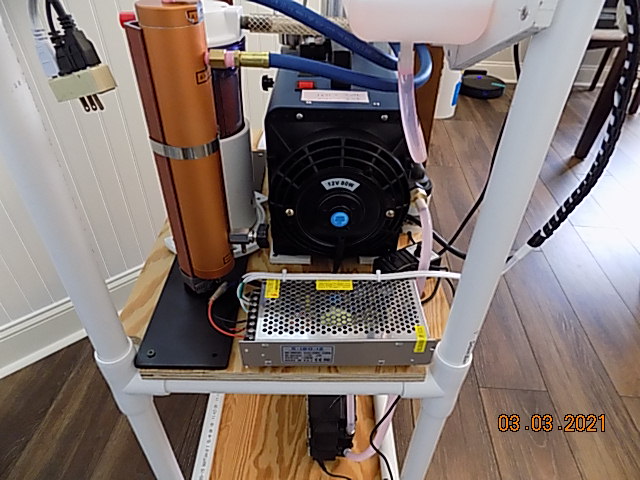

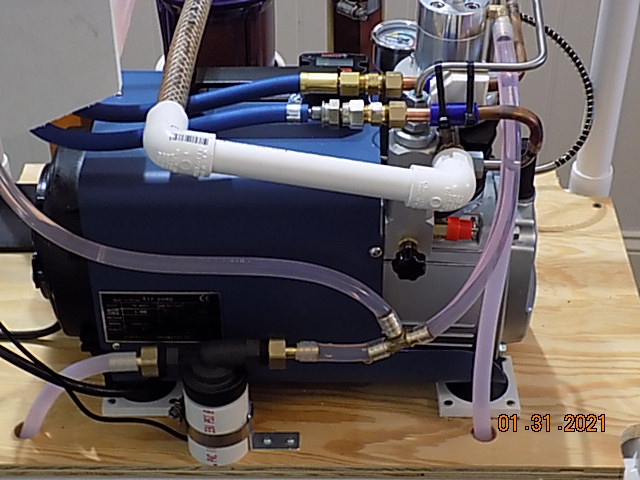

I'm new to Airgun Nation and PCP air rifles. I've had a Sheridan Blue Streak since the late 60s. Recently bought a Daystate Huntsman Regal XL .177 and a Benjamin Armada .22. So that brings me to the need for a charging station. As a retired person, I have time to spend with my pursuits and tend to overdue things.. I originally bought a Tuxing single cylinder as I liked the internal air passages and large cooling water surrounded high pressure piston. Unfortunately, it arrived with casting broken and bends in all the sheet metal. Delivered by air drop I guess!! While waiting to get the damage compressor resolved, I bought a Yong Heng with the low side condenser and manual shut off. I read many threads and watch many videos on modifications made by other to improve cooling and remove moisture. To begin my mods, I added a low side cooling tower. I cut the stainless tube running from the low side output and silver soldered a copper tube to each of the cut ends. I installed compression fittings and high temp / pressure flex hose to the tower cooler and back to the original low side condenser. Air from the low side condenser follows the original path to the high side piston on to the output whip. To further reduce moisture, the output whip is connected to a large heavy wall filter / dryer … mine being filled as a molecular sieve. The gold dryer has a bleed valve below the foster compressor connection for additional moisture release. As many have already learned, fittings and adapters rated for 6000 psi to join the parts in the manner I wanted, took some time to source. I had to machine several myself to reduce the number of threaded connections. As part of my moisture control, I plumbed an intake air desiccant canister. Lots of discussions concerning effectiveness but its there. With the pressure side configured for the moisture removal as I wanted, I moved on to the compressor cooling … water and air. I removed the funky shaft mounted fan and grill at the rear of the motor and replaced it with a 6” 12V push fan. Moves lots of air through the motor shroud and across the low pressure cylinder. I fabricated a closed water cooling system that circulates distilled water with water wetter and a small amount of anti-freeze. After watching Yong Heng repair videos and seeing the large amount of deposits on the outside of the high pressure cylinder, inside the water jacket, I wanted something better. I assume the deposits are left from the super high temperature of the high pressure cylinder spot boiling the cooling water and leaving the tap water mineral deposits that will reduce the heat transfer. As others have done, I have added a 3 fan, all copper radiator. A 12V 3.5 gal/min centrifugal pump located below the cylinder output, is always flooded, pushing coolant through the radiator and up to the lower inlet of the high pressure cylinder. The 12V DC components are powered by a 15A switching power supply. I still monitor compressor temperature and would manually limit high temperature to 65C. Stabilization temperature is about 62C with 70F room temp for the 15 minutes it takes to top up the SCBA tank. All the above configuration is mounted in a multi level PVC pipe cage on casters. Lots of small personal nuances that I didn't bother to document. My rendition of a PCP charging station that works for me.

FYI: Before the closed cooling system was finished, I needed air to shoot. I charged my 2 SCBA tanks from “0” to 4200 psi in 5 steps of about 15 min each with cool down between. I maintained 2000 PSI sieve dryer pressure by just cracking tank valve until tank pressure reached the 2000 threshold. Worked well but took almost half a day and lots of ice with the original submersible pump.

FYI: Before the closed cooling system was finished, I needed air to shoot. I charged my 2 SCBA tanks from “0” to 4200 psi in 5 steps of about 15 min each with cool down between. I maintained 2000 PSI sieve dryer pressure by just cracking tank valve until tank pressure reached the 2000 threshold. Worked well but took almost half a day and lots of ice with the original submersible pump.