Good Morning, afternoon, evening all. I would like to hear from the members here today about greases you all use for pcp assembly. I mean the metal on metal..threads, guides etc. Back then (pre 2000) Honda moly 60 was my go to in those areas in all my Korean airguns.. I haven't done it since I lost track of the tube years ago. I applied very little and never used it on my motorcycles, as it was to be very expensive. So what grease if any, do you all use? Moly 60 was supposed to be all synthetic and 60% moly but I never had a way to test it. It never went boom but I wouldn't expect it to on threads. It worked so well I never had galling and disassembly was a breeze.. Go

- The AGN App is ready! Search "Airgun Nation" in your App store. To compliment this new tech we've assigned the "Threads" Feed & "Dark" Mode. To revert back click HERE.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Moly grease.

- Thread starter MACTEN

- Start date

Same thing I used to use.. They just changed the name to m-77 except it's cheaper... :0Here's what I've been using found on amazon 20 bucks

View attachment 327793

Upvote 0

I recently purchased a Gamo Urban for a friend and it's manual says not to use silicon base lubes that they can harm the finish. The manual reads to use

Molykote 111. I ordered some because I really liked the sample pack that shipped with the airgun.

Molykote 111. I ordered some because I really liked the sample pack that shipped with the airgun.

Upvote 0

Custom Moly Lubricants

Maccari Custom Airgun Shop. Airguns and related accessories. Springs,tune kits,gunstocks,Beeman, Rws, Webley and many others. Sales and service

www.airrifleheadquarters.com

Upvote 0

That is silicone based lube..I recently purchased a Gamo Urban for a friend and it's manual says not to use silicon base lubes that they can harm the finish. The manual reads to use

Molykote 111. I ordered some because I really liked the sample pack that shipped with the airgun.

View attachment 327797

Upvote 0

That's only for the o-rings which everyone should use silicone (silicone based molykote 111 lube) .. So they aren't saying to use the lube on the metal to metal parts. In fact the opposite.. I was asking what people use for their metal to metal parts like moly etc.

Upvote 0

For me, there are only a couple of places in a typical PCP where I will use a wet molybdenum disulfide lubricant, and those are the pivot points of a cocking linkage or the contact points of a trigger group.

For the hammer and bolt, I prefer to burnish dry MoS2 into the surfaces for two reasons. One is to eliminate the potential for temperature-induced velocity changes resulting from the changing viscosity of a wet lube. The other is that a dry lube does not promote the accumulation of dirt and grit.

The only other example I can think of is a threaded connection potentially at risk of galling, and for that I like using tungsten disulfide. A 50/50 blend (by volume) of WS2 and alcohol in a dropper makes it easy to apply. The alcohol helps carry the powder into the threads and then quickly evaporates.

For the hammer and bolt, I prefer to burnish dry MoS2 into the surfaces for two reasons. One is to eliminate the potential for temperature-induced velocity changes resulting from the changing viscosity of a wet lube. The other is that a dry lube does not promote the accumulation of dirt and grit.

The only other example I can think of is a threaded connection potentially at risk of galling, and for that I like using tungsten disulfide. A 50/50 blend (by volume) of WS2 and alcohol in a dropper makes it easy to apply. The alcohol helps carry the powder into the threads and then quickly evaporates.

Upvote 0

That's only for the o-rings which everyone should use silicone (silicone based molykote 111 lube) .. So they aren't saying to use the lube on the metal to metal parts. In fact the opposite.. I was asking what people use for their metal to metal parts like moly etc.

I'm sure you're right. I didn't know it could cause damage to a metal surface.

I use CLP on the cocking linkage , trigger , hammer.

I have used Permatex anti-seize on spark-plugs and headbolts. Places where steel bolts go into aluminum to prevent galling. Not sure its appropriate for your application but it's good stuff.

Upvote 0

I use anti-seize on external steel to aluminum screws/bolts that have a tendency to gall. I've heard of others that use it on the threads i'm talking about but I won't.. i'm sure it's just fine but likely has a petroleum base. CLP should be fine for the linkage and cocking lever joints but I would leave the hammer dry or put some graphite dry lube only on it.I'm sure you're right. I didn't know it could cause damage to a metal surface.

I use CLP on the cocking linkage , trigger , hammer.

I have used Permatex anti-seize on spark-plugs and headbolts. Places where steel bolts go into aluminum to prevent galling. Not sure its appropriate for your application but it's good stuff.

Upvote 0

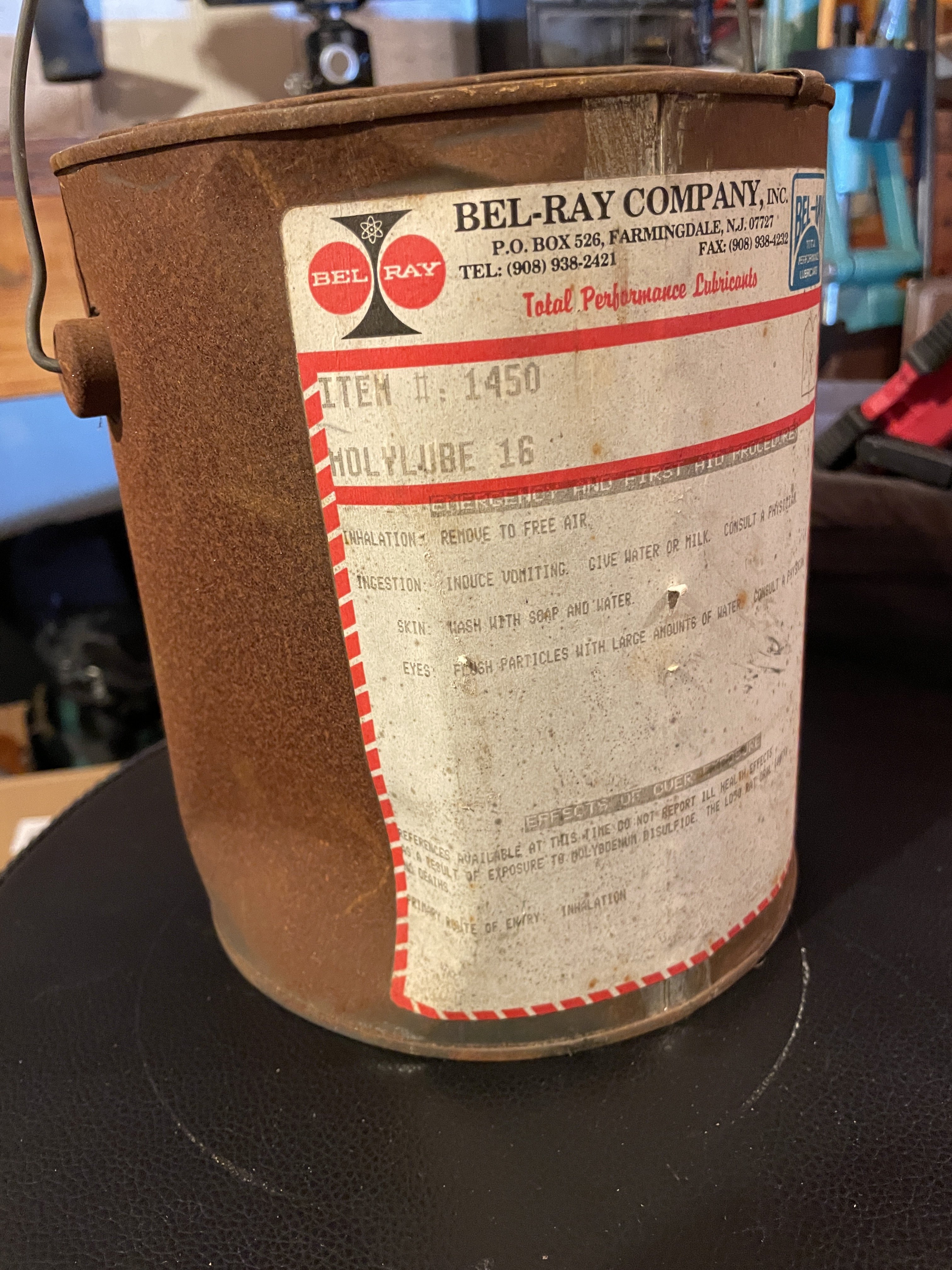

I’ve used this dry moly for yrs. As you can tell by the can!, burnished into metal to metal sliding or friction type contact it is super slick and and stays put.

I have used nickel anti-seize for stainless to stainless threads and high temp. copper for other metals.

I am very fortunate to have access to about any type of anti-seize or dry lubricant I could ever use and seen it in use over the yrs. (I will never even come close to using that gallon can of Moly, my kids or grand kids might make a dent in it!)

I have used nickel anti-seize for stainless to stainless threads and high temp. copper for other metals.

I am very fortunate to have access to about any type of anti-seize or dry lubricant I could ever use and seen it in use over the yrs. (I will never even come close to using that gallon can of Moly, my kids or grand kids might make a dent in it!)

Last edited:

Upvote 0

Also for some "need easy sliding" surfaces I can recommend a high PTFE content spray, you can get it from any pro-bike shop that services profesional cyclists bikes. Ask for a shifter or brake cable - wire lube.

Upvote 0

Why Moly again? Airguns don’t really have that level of sheer pressure to use moly, granted it doesn’t really hurt but doesn’t do much either. Even tip if the trigger sheer won’t have the level of pressure that requires moly. In automotive world only time moly is used is just in the axles or U-joints.

For Metal on metal without orings then a tiny dab of good lithium grease would do. Silicon grease is for orings, more specifically silicon grease does not degrade orings. Keep in mind most lithium grease does attract dirt so use sparingly. For hammer weight, just keep it clean or use some graphite if you insist on lube for some reason.

For Metal on metal without orings then a tiny dab of good lithium grease would do. Silicon grease is for orings, more specifically silicon grease does not degrade orings. Keep in mind most lithium grease does attract dirt so use sparingly. For hammer weight, just keep it clean or use some graphite if you insist on lube for some reason.

Upvote 0

I'm not sure how much aluminum is in the various air rifles around, the couple pcp's i have make it seem to be the metal of choice, so this should be of interest/concern to most.

Graphite and aluminum do not get along! The two materials will cause galvanic etching/corrosion. That said, I don't know why one would, but don't clean aluminum with Simple Green - it will eat it.

I picked this info up years ago when I was way more into motorcycling than I currently am. The Simple Green bit came from an aircraft mechanic that said the FAA would shut down an airport if they found it due to the way it attacked aluminum. I don't recall where the graphite bit came from, but verified by an Andrews engineer when I worked cable tv.

Graphite and aluminum do not get along! The two materials will cause galvanic etching/corrosion. That said, I don't know why one would, but don't clean aluminum with Simple Green - it will eat it.

I picked this info up years ago when I was way more into motorcycling than I currently am. The Simple Green bit came from an aircraft mechanic that said the FAA would shut down an airport if they found it due to the way it attacked aluminum. I don't recall where the graphite bit came from, but verified by an Andrews engineer when I worked cable tv.

Upvote 0

Simple green and purple power both etch aluminum really well. If you don't have a blast cabinet and are wanting to paint, both are fairly effective are giving a better substrate than sanding for instance.I'm not sure how much aluminum is in the various air rifles around, the couple pcp's i have make it seem to be the metal of choice, so this should be of interest/concern to most.

Graphite and aluminum do not get along! The two materials will cause galvanic etching/corrosion. That said, I don't know why one would, but don't clean aluminum with Simple Green - it will eat it.

I picked this info up years ago when I was way more into motorcycling than I currently am. The Simple Green bit came from an aircraft mechanic that said the FAA would shut down an airport if they found it due to the way it attacked aluminum. I don't recall where the graphite bit came from, but verified by an Andrews engineer when I worked cable tv.

Upvote 0

CMD Anti - Scoring Extreme Pressure Lube #3 works great on screw threads and other areas where metal galling may occur. I use it primarily on the brass tips of a lathe steady rest and it prevents scoring. You may have to reapply it occasionally but it's the best I've ever used. I purchase it in 4 ounce tubes.

Upvote 0