As others have implied, removing all water vapor from air before compression is difficult because there can be so much of it (but it is not impossible). A cubic meter of air like you describe could have close to 20 grams of water vapor in it, even though you can't see it! It would take a huge amount of desiccant to accomplish the task.

That said, if I wanted to do it, I would do it this way: the first thing I would do is try to draw my air source from a cold place, because when air is chilled water vapor is removed (most commercial high flow air driers use chillers). If you could draw the air out of a freezer that is running, that might remove about 75% of the water vapor right there - of course that does mean that it will form frost in the freezer, so more defrosting (or defrost cycles) will be needed on the freezer. And also air would need to be able to get into the freezer to replace what is being sucked out. The best way to do this might be with a closed path of air flowing through a cooling coil or radiator placed in the freezer - then there would be no buildup of frost in the freezer either . . .

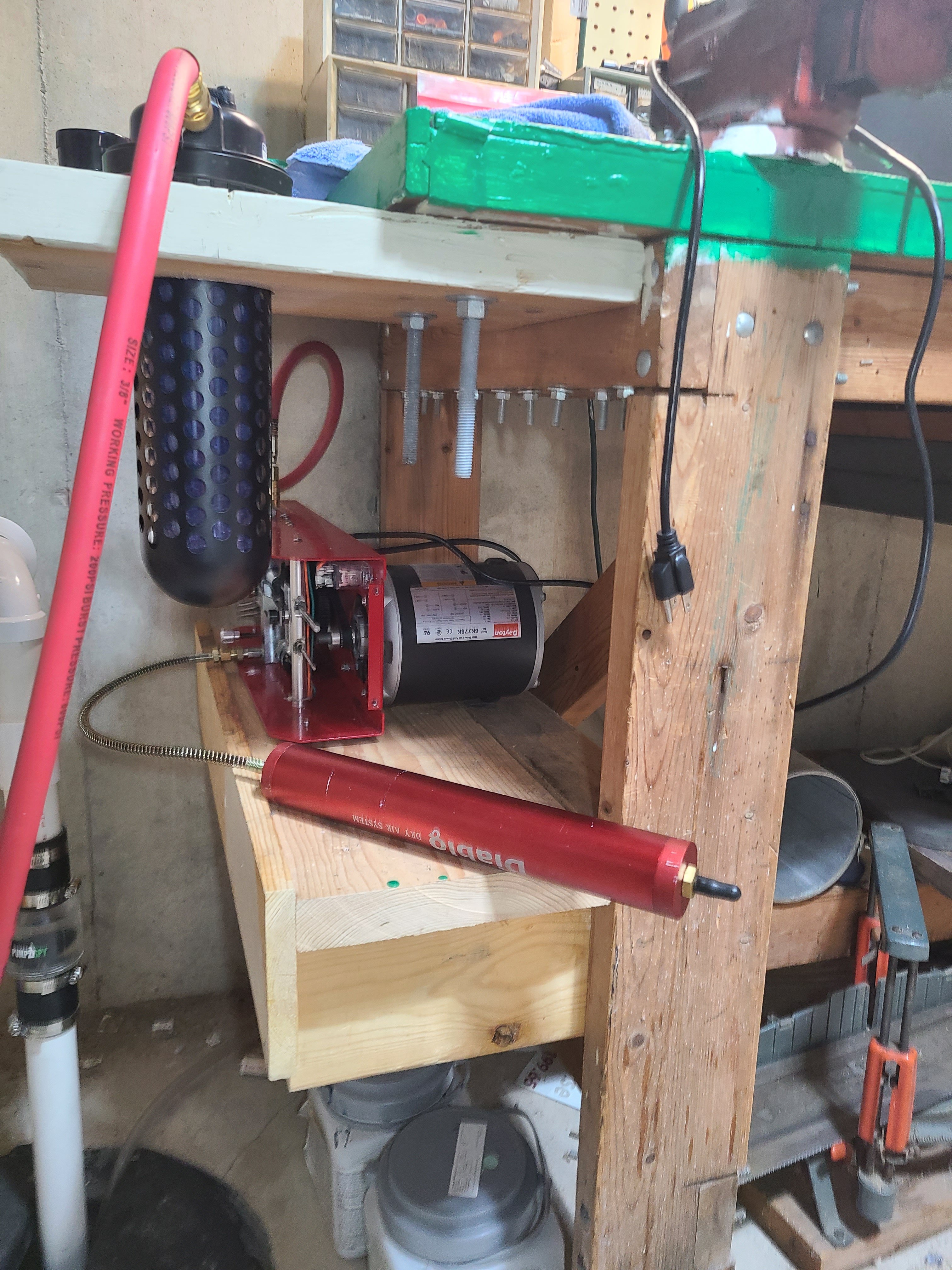

Then I would feed that air through a still large desiccant filter that I would make with PVC pipe - may 3 to 4 inch in diameter and about 2 feet in length, thus holding several pounds of desiccant. And I would put a regular filter after it to trap any dust or dirt too. Part of the reason for for going so big is to reduce the airflow resistance into the compressor - I'm sure that if the resistance is too large it would be bad for the compressor . . . but I don't know. Worst case one could feed the air path going into the hose going into the freezer at a few psi, perhaps regulated from a shop compressor . . .

Of course if one were to do that (feed with a shop compressor), they could just use the shop compressor as the first stage of drying just like us Shoebox users do - once the air has cooled off after being compressed to about 100 psi, about 90% of the water will condense out there. That is one of the things that makes getting dry air so easy with a Shoebox, as we have easy access to dry the air after the first stage of compression, which is probably the most efficient place to do it overall (it dramatically reduces the amount of desiccant needed, without increasing the time needed to compress air into the tank by "wasting" time spent filling the desiccant filter with fully pressurized air). So if you could regulate it low enough at the right flow rate, you could feed it into the same dryers we Shoebox users are using - that Wilkerson unit is great.

Anyways, that is how I would go about it. Hope it helps