can someone help me understand these things, this a new reg that just started a creep, nothing like the old one i had but still maybe 10 bar, i cleaned it a tiny bit, and it fixed the creep a bit, almost as if it was new, but it started slippin again,  Can dirty air damage it? What should i try to help it? Where does creep even happen?

Can dirty air damage it? What should i try to help it? Where does creep even happen?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

maybe i can fix this reg?

- Thread starter mikeairguns

- Start date

Ahh the gen 4 RTI reg. If someone has the secret remedy for the RTI regs let them know at RTI so we can get a solid, non creeping reg version. I think some will tell you all regs creep some. It is just a matter of how much creep you can tolerate.

Upvote 0

I'm not familiar with that specific regulator but I can offer some general thoughts.

What pressure are you filling your reservoir to? Sometimes regulators are more prone to creep with fill pressure is approaching 300 bar. Perhaps keeping below 250 bar might help. When the main seal separating the air reservoir from the plenum takes a set or deforms and begins to leak, the plenum will pressurize higher than the regulator's set pressure. That is the definition of creep that I am familiar with. Lubricating the O-ring seals with silicone grease on all surfaces, inside the groove and not just on the OD of the rings will help with overall sealing ability. This means removing an O-ring completely, coating it with grease, then installing it. If it's not fully lubed at the factory, this could be a weak link.

If a leaking seal is not the problem then is this regulator prone to stiction where it cannot mechanically maintain its setting? If so, then perhaps some polishing and lubrication can help.

I've watched videos from Ernest Rowe where he is tuning up a regulator by polishing all of the bearing surfaces for the seals and the Belleville washers using polishing paste such as flitz and 3M abrasive papers. Then all of the surfaces have been wiped with a sparing amount of silicone grease, just a thin film wiped with fingers.

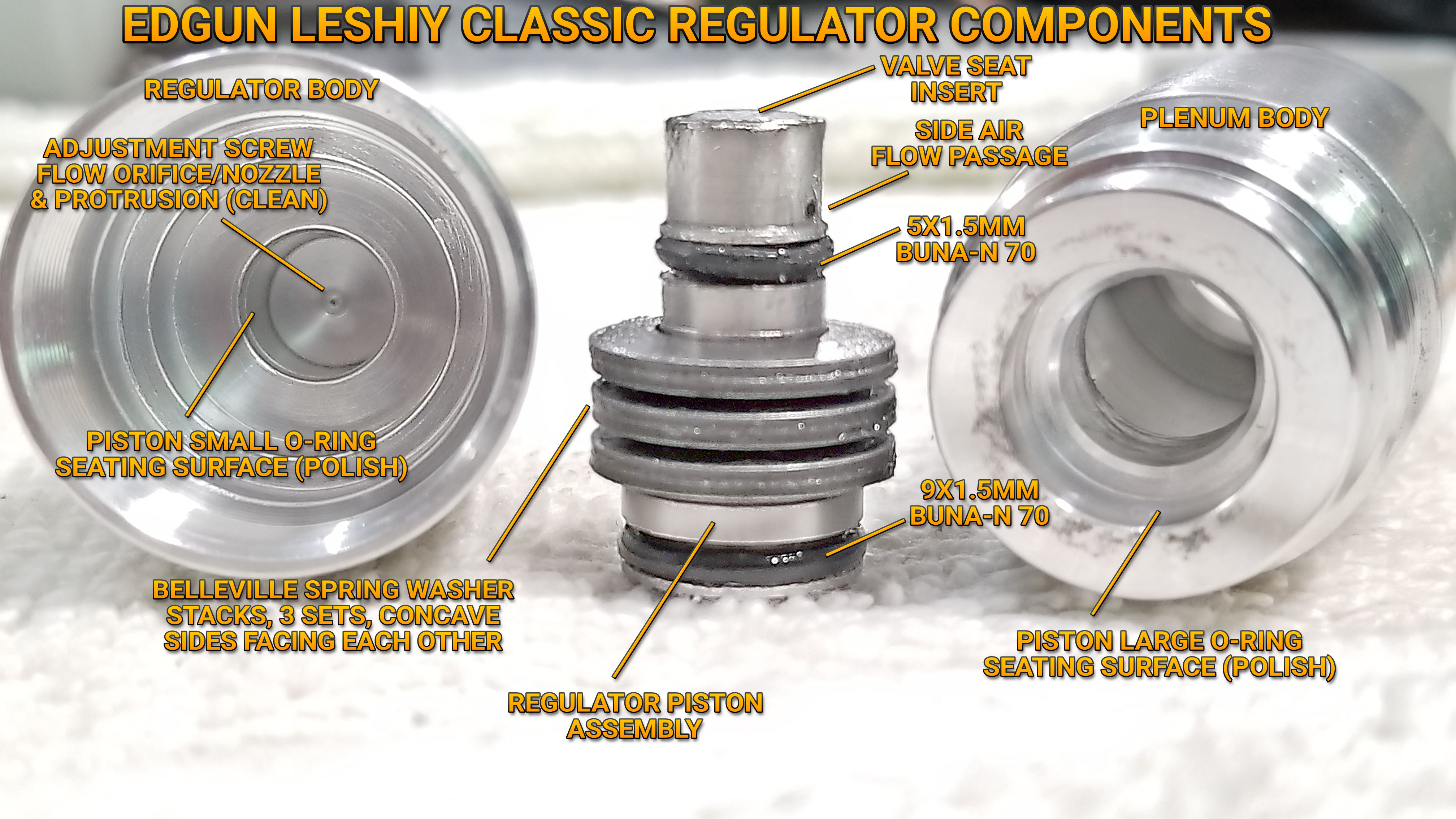

I don't see any shiny spots on your Belleville washers where the edges touch so they are definitely not broken in yet. I polished mine by applying flitz polishing paste and rubbing them on old bits of terry cloth. You can see smooth shiny areas appear after this. I did this to my Edgun regulators. Here are some pics from the Leshiy Classic regulator tune up I did and you can see the polished shiny circles on the washers for instance. I notated and polished surfaces where O-rings slide when the regulator piston makes its tiny movements after each shot cycle. This should give you some ideas for perhaps tuning up your own reg. Make sure to find out where the tiny valve sealing surface face is and little air passages and make sure everything is free of debris, smooth and clean.

Your regulator parts look pretty smooth and fairly well polished in the photo as far as I could tell. The construction is different so I'm sure others who have done this will have more to offer.

GL

Feinwerk

What pressure are you filling your reservoir to? Sometimes regulators are more prone to creep with fill pressure is approaching 300 bar. Perhaps keeping below 250 bar might help. When the main seal separating the air reservoir from the plenum takes a set or deforms and begins to leak, the plenum will pressurize higher than the regulator's set pressure. That is the definition of creep that I am familiar with. Lubricating the O-ring seals with silicone grease on all surfaces, inside the groove and not just on the OD of the rings will help with overall sealing ability. This means removing an O-ring completely, coating it with grease, then installing it. If it's not fully lubed at the factory, this could be a weak link.

If a leaking seal is not the problem then is this regulator prone to stiction where it cannot mechanically maintain its setting? If so, then perhaps some polishing and lubrication can help.

I've watched videos from Ernest Rowe where he is tuning up a regulator by polishing all of the bearing surfaces for the seals and the Belleville washers using polishing paste such as flitz and 3M abrasive papers. Then all of the surfaces have been wiped with a sparing amount of silicone grease, just a thin film wiped with fingers.

I don't see any shiny spots on your Belleville washers where the edges touch so they are definitely not broken in yet. I polished mine by applying flitz polishing paste and rubbing them on old bits of terry cloth. You can see smooth shiny areas appear after this. I did this to my Edgun regulators. Here are some pics from the Leshiy Classic regulator tune up I did and you can see the polished shiny circles on the washers for instance. I notated and polished surfaces where O-rings slide when the regulator piston makes its tiny movements after each shot cycle. This should give you some ideas for perhaps tuning up your own reg. Make sure to find out where the tiny valve sealing surface face is and little air passages and make sure everything is free of debris, smooth and clean.

Your regulator parts look pretty smooth and fairly well polished in the photo as far as I could tell. The construction is different so I'm sure others who have done this will have more to offer.

GL

Feinwerk

Last edited:

Upvote 0

Hi @mikeairguns !I'm not familiar with that specific regulator but I can offer some general thoughts.

What pressure are you filling your reservoir to? Sometimes regulators are more prone to creep with fill pressure is approaching 300 bar. Perhaps keeping below 250 bar might help. When the main seal separating the air reservoir from the plenum takes a set or deforms and begins to leak, the plenum will pressurize higher than the regulator's set pressure. That is the definition of creep that I am familiar with. Lubricating the O-ring seals with silicone grease on all surfaces, inside the groove and not just on the OD of the rings will help with overall sealing ability. This means removing an O-ring completely, coating it with grease, then installing it. If it's not fully lubed at the factory, this could be a weak link.

If a leaking seal is not the problem then is this regulator prime to stiction where it cannot mechanically maintain its setting? If so, then perhaps some polishing and lubrication can help.

I've watched videos from Ernest Rowe where he is tuning up a regulator by polishing all of the bearing surfaces for the seals and the Belleville washers using polishing paste such as flitz and 3M abrasive papers. Then all of the surfaces have been wiped with a sparing amount of silicone grease, just a thin film wiped with fingers.

I don't see any shiny spots on your Belleville washers where the edges touch so they are definitely not broken in yet. I polished mine by applying flitz polishing paste and rubbing them on old bits of terry cloth. You can see smooth shiny areas appear after this. I did this to my Edgun regulators. Here are some pics from the Leshiy Classic regulator tune up I did and you can see the polished shiny circles on the washers for instance. I notated and polished surfaces where O-rings slide when the regulator piston makes its tiny movements after each shot cycle. This should give you some ideas for perhaps tuning up your own reg. Make sure to find out where the tiny valve sealing surface face is and little air passages and make sure everything is free of debris, smooth and clean.

Your regulator parts look pretty smooth and fairly well polished in the photo as far as I could tell. The construction is different so I'm sure others who have done this will have more to offer.

GL

Feinwerk

View attachment 301742

View attachment 301743

View attachment 301744

@Feinwerk has covered it all on the creep. i observed similar behavior on my FX Maverick and found out the regulators' belleville washers weren't broken-in yet... polished them and now it's all good.

Upvote 0

Feinwerk’s detailed explanation and photo markups are an excellent reference. My only comment is that I have repaired dozens of creeping regulators and the thing to really focus in on is the surface quality of the plastic seal at the end of the piston and that of the orifice it presses against. Inspect both surfaces with the aid of magnification and good lighting. Typically the cause is wear of the plastic seal but occasionally the orifice (typ. a truncated cone feature) will have a scratch or minor defect. Concentric machining marks, if they are very faint, aren’t as big of a concern but any radial scratches need to be worked out.

Other possible contributors like burrs on the edges of the Belleville washers are a distant second but might as well check and deal with it while you have the regulator apart, if for no other reason than the peace of mind.

Regarding the O-rings, you want them clean and lubricated so they will seal well and last a long time in this dynamic application. However nothing about them can contribute to pressure creep.

Other possible contributors like burrs on the edges of the Belleville washers are a distant second but might as well check and deal with it while you have the regulator apart, if for no other reason than the peace of mind.

Regarding the O-rings, you want them clean and lubricated so they will seal well and last a long time in this dynamic application. However nothing about them can contribute to pressure creep.

Upvote 0

Holy, why dont i get notifications, ik ik very late but i want to thank you all for the info, i havent read all of it yet but will look into it and see if i can sort this, the reg is new and creeps 10 bar now at any pressure, and its rather a fast creep, so not a over night thing, more like 15 seconds, again thanks again, i will try to check in, im on my break rn so no time to read it all but after work ill lool more into it

Upvote 0

If it creeps 10 bar and it takes 15 seconds, that isn’t creep. That’s recovery time. Recovery time is addressed with the washers then possibly polishing the spool. RTI side fed regs are different in the seat area. I think you need to finish disassembling the thing and work on polishing the metal part that makes contact with plastic part.

Upvote 0

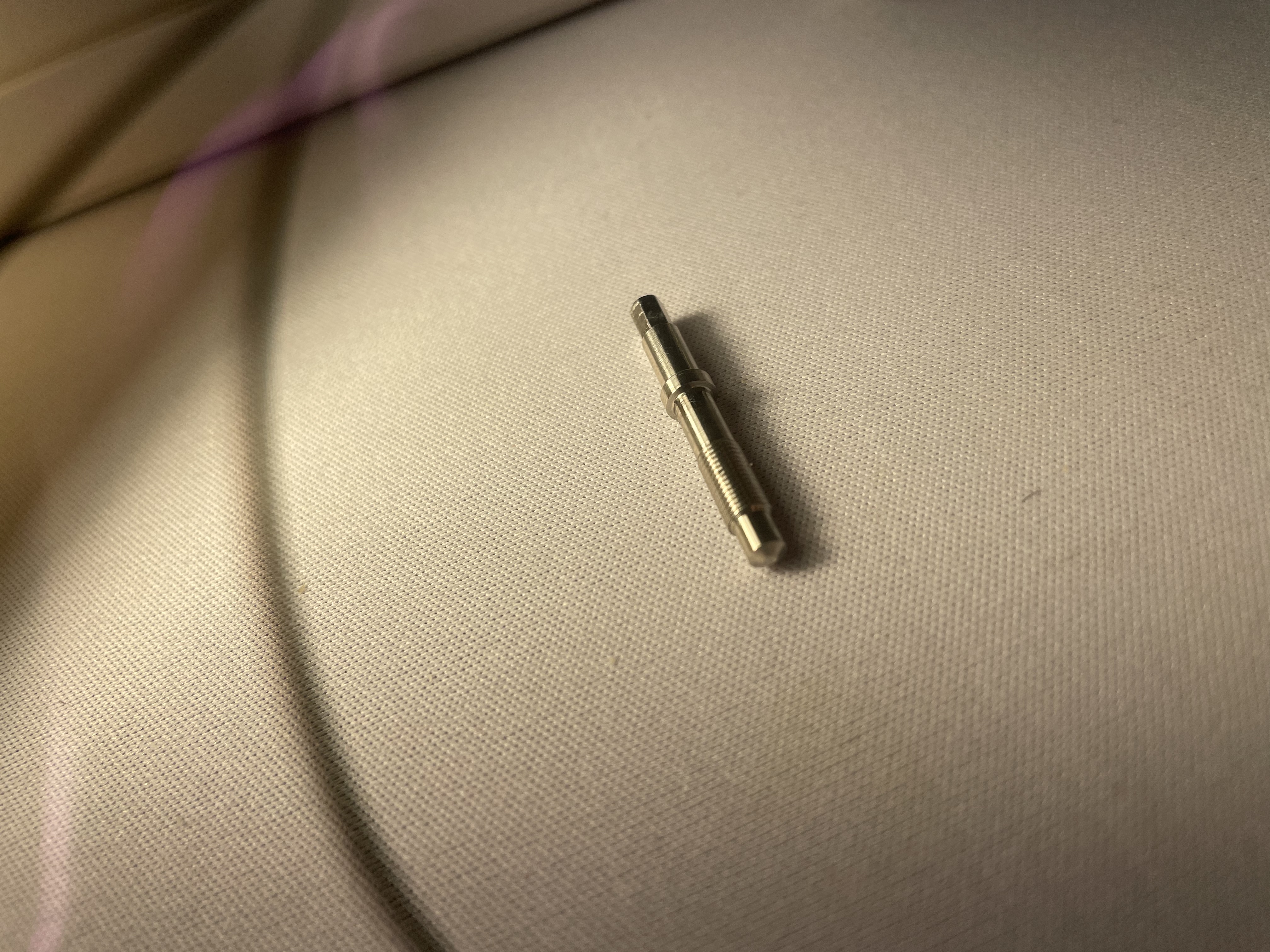

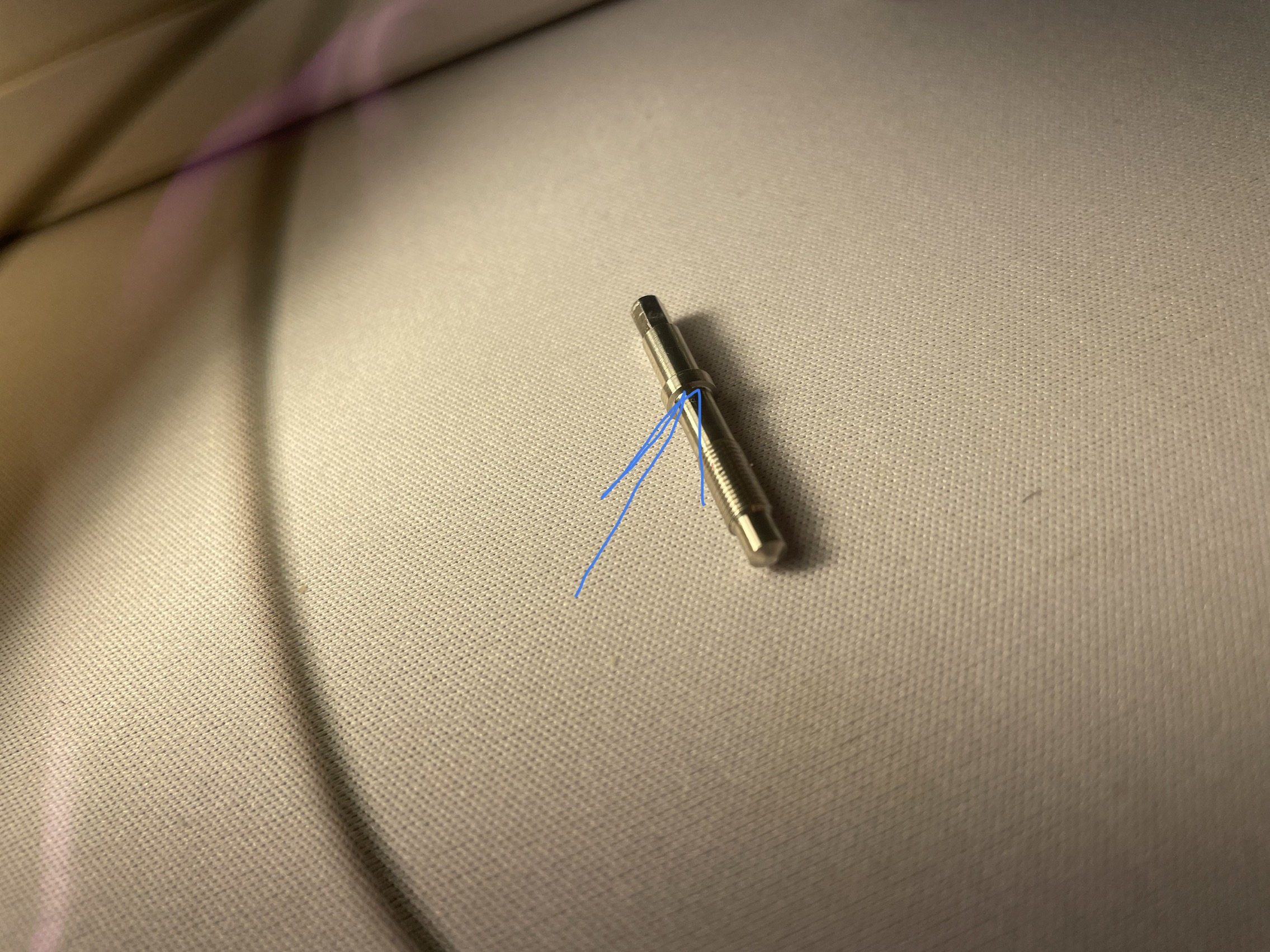

Take this apart and polish the business end of the metal cylinder thing with some 2k grit. I’m just guessing because I don’t have the latest gambler from RTI but that cylindrical piece looks like it has bite marks on it from when they grabbed it to screw it into the spool.

Upvote 0

Ok i see a tiny mark on the black plastic, i tried taking it off the rod but i don’t think it’s possible, at least with my handsTake this apart and polish the business end of the metal cylinder thing with some 2k grit. I’m just guessing because I don’t have the latest gambler from RTI but that cylindrical piece looks like it has bite marks on it from when they grabbed it to screw it into the spool.

View attachment 307596

Upvote 0

Maybe mark causing the crrep?Ok i see a tiny mark on the black plastic, i tried taking it off the rod but i don’t think it’s possible, at least with my hands

Upvote 0

Ok i took it apart, i got some nice photos, if there’s anything wrong and that i can fix let me know, i dont have any fine sandpaper at the moment, only fine wet stone so ill wait on any of the work unless the stone can be used?

Upvote 0

You forgot to post a pic of the most important piece. The piece that you need to work on. And NO, don’t go anywhere near it with that wet stone. You need to dress the side of the cylindrical piece with the treads on it that makes contact with that black plastic disc.

Upvote 0

Haha, ok ok, maybe i shouldve waited, already went crazy with the stone  I polished the metal disk that touches the black washer thing, im guessing the part that matters is this what contacts the washer on the rod - - - upon inspection i do see some tiny markings on one side of it, i dont know if id be able to clean that up with anything i have, so maybe the end of the road for me?

I polished the metal disk that touches the black washer thing, im guessing the part that matters is this what contacts the washer on the rod - - - upon inspection i do see some tiny markings on one side of it, i dont know if id be able to clean that up with anything i have, so maybe the end of the road for me?

Upvote 0

This flat edge and the plastic surface it makes contact with need to be perfect. 2,000 grit sandpaper perfect. If you took a stone to anything, you’re done.

Upvote 0

Yeah you definitely don’t want to use anything aggressive unless you can see a specific defect like a radial scratch going across the shoulder that needs to be worked down. And if that were the case, the material would need to be worked down uniformly around the entire shoulder so as not to leave a low spot. Otherwise don’t do anything outside of polishing or lapping.

The goal is to make the shoulder meet as neatly as possible with the corresponding region on the plastic seat, so they can promptly form an air-tight seal without having to be squeezed together with a great deal of force. I would say the most foolproof way of achieving this fit is by lapping the surfaces together with a light abrasive. Anything finer than ~1000 grit (e.g. J-B Bore Compound) is a waste of time in my experience. Don’t rush it where heat could build up and compromise the plastic, and frequently replenish/redistribute the abrasive to the target area. Occasionally wipe clean and inspect the contact surfaces in good light with the aid of magnification. The surfaces in contact with each other should eventually take on a completely uniform appearance absent of any discontinuities, at which point that is a good clue they are well matched and should be capable to sealing nicely to each other.

The goal is to make the shoulder meet as neatly as possible with the corresponding region on the plastic seat, so they can promptly form an air-tight seal without having to be squeezed together with a great deal of force. I would say the most foolproof way of achieving this fit is by lapping the surfaces together with a light abrasive. Anything finer than ~1000 grit (e.g. J-B Bore Compound) is a waste of time in my experience. Don’t rush it where heat could build up and compromise the plastic, and frequently replenish/redistribute the abrasive to the target area. Occasionally wipe clean and inspect the contact surfaces in good light with the aid of magnification. The surfaces in contact with each other should eventually take on a completely uniform appearance absent of any discontinuities, at which point that is a good clue they are well matched and should be capable to sealing nicely to each other.

Upvote 0

Yh when i was looking at that area, it looked smooth but one side on the underneath portion had a couple of lil markings. I definitely dont feel comfortable sanding that part down as the suface is too small, ill look into the polish compound and see how i feel. Again guys, thanks for all the help

Upvote 0

@mikeairguns ,

Chuck the spindle piece lightly in your hand drill. Apply simichrome or flitz paste to a swab and push it against that tapered shoulder area while spinning with the drill to polish. You'll see black color appear on the swab when you're doing it right; that will be microscopic surface metal coming off. The surface will get amazingly smooth and shiny without changing its contour as would happen with aggressive sanding or stoning.

GL,

Feinwerk

Chuck the spindle piece lightly in your hand drill. Apply simichrome or flitz paste to a swab and push it against that tapered shoulder area while spinning with the drill to polish. You'll see black color appear on the swab when you're doing it right; that will be microscopic surface metal coming off. The surface will get amazingly smooth and shiny without changing its contour as would happen with aggressive sanding or stoning.

GL,

Feinwerk

Upvote 0