Upvote 0

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Marauder Semi-auto power tune mods

- Thread starter Airgun-hobbyist

- Start date

It has been a while since I was inside of my valve body, but I do recall that I ported right up to the seat and that is as far as I went. I did not try to mess with the valve seat area because they are really tricky to get a good seal on (if the cutting bit is chattering.).

As far as...

"On question about the valve seat: I only have bad pictures of this, but I am assuming the seat is on the outside of the small space before the stem passes through the valve body where the exhaust port is? It looks like the port is set back in that space towards the stem guide part of the valve so potentially that part of the port could be pretty big? Ill post some pics to help explain"

You don't always want to just hog out material with the theory that bigger porting is always better. Too much air space can create a low pressure zone that robs air flow velocity or worse.

The SAM somehow works on the hammer bounce principle, according to the engineers. They did a lot of testing to perfect the reloading semi-automatic feature and if you open up the wrong area to a low pressure zone the valve may not "bounce" and have the additional air needed to cycle. This is explained a little in the article Part 2.

Something that I have found through several port and polish jobs over the years is that the initial gains from porting are usually the most gains. Smooth and radius the edges to remove sharp corners and transitions is best done slowly and with an eye for detail. And when you think that you are close,you probably are, so the gains are only netting an additional foot to two in speed at that point. It is best to lay down the tools and admire your work at this point.

https://hardairmagazine.com/news/exclusive-first-in-depth-look-at-the-benjamin-marauder-semi-auto-air-rifle/

https://hardairmagazine.com/news/exclusive-first-in-depth-look-at-the-benjamin-marauder-semi-auto-air-rifle-2/

As far as...

"On question about the valve seat: I only have bad pictures of this, but I am assuming the seat is on the outside of the small space before the stem passes through the valve body where the exhaust port is? It looks like the port is set back in that space towards the stem guide part of the valve so potentially that part of the port could be pretty big? Ill post some pics to help explain"

You don't always want to just hog out material with the theory that bigger porting is always better. Too much air space can create a low pressure zone that robs air flow velocity or worse.

The SAM somehow works on the hammer bounce principle, according to the engineers. They did a lot of testing to perfect the reloading semi-automatic feature and if you open up the wrong area to a low pressure zone the valve may not "bounce" and have the additional air needed to cycle. This is explained a little in the article Part 2.

Something that I have found through several port and polish jobs over the years is that the initial gains from porting are usually the most gains. Smooth and radius the edges to remove sharp corners and transitions is best done slowly and with an eye for detail. And when you think that you are close,you probably are, so the gains are only netting an additional foot to two in speed at that point. It is best to lay down the tools and admire your work at this point.

https://hardairmagazine.com/news/exclusive-first-in-depth-look-at-the-benjamin-marauder-semi-auto-air-rifle/

https://hardairmagazine.com/news/exclusive-first-in-depth-look-at-the-benjamin-marauder-semi-auto-air-rifle-2/

Upvote 0

Makes sense to me. It sounds like to turning up the reg pressure and expanding the plenum are the two untested options for power gains with low risk... So a little bit of polishing and I will call that done. Thanks for the reminder about hammer bounce also. I need to get the final plenum size and reg pressure and then adjust the hammer to that id I understand correctly. I turned the HS back where it was for the previous tests and shot a magazine to confirm. Then took it another half turn out (so something like 8 turns in total) and shot another string just to out of curiosity. The 9 shots is me not having the app running with the first shot... twice in a row... both fresh fill to 3000 psi. Ill get the higher reg pressure test posted tomorrow I hope.

about 8 turns in HS:

Shot count: 9

Low: 905

Hi: 912

Avg: 909

Spread: 7

STD Dev: 2.0

912

909

909

909

909

912

909

905

909

About 8.5 turns in HS:

Shot count: 9

Low: 909

Hi: 926

Avg: 915

Spread: 17

STD Dev: 4.7

926

914

914

914

912

916

914

912

909

about 8 turns in HS:

Shot count: 9

Low: 905

Hi: 912

Avg: 909

Spread: 7

STD Dev: 2.0

912

909

909

909

909

912

909

905

909

About 8.5 turns in HS:

Shot count: 9

Low: 909

Hi: 926

Avg: 915

Spread: 17

STD Dev: 4.7

926

914

914

914

912

916

914

912

909

Upvote 0

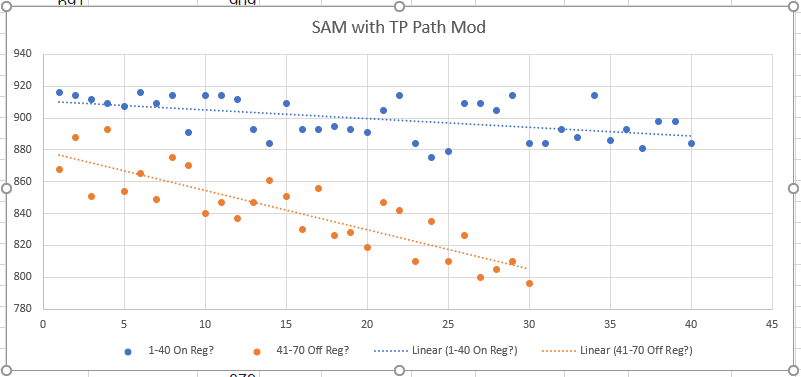

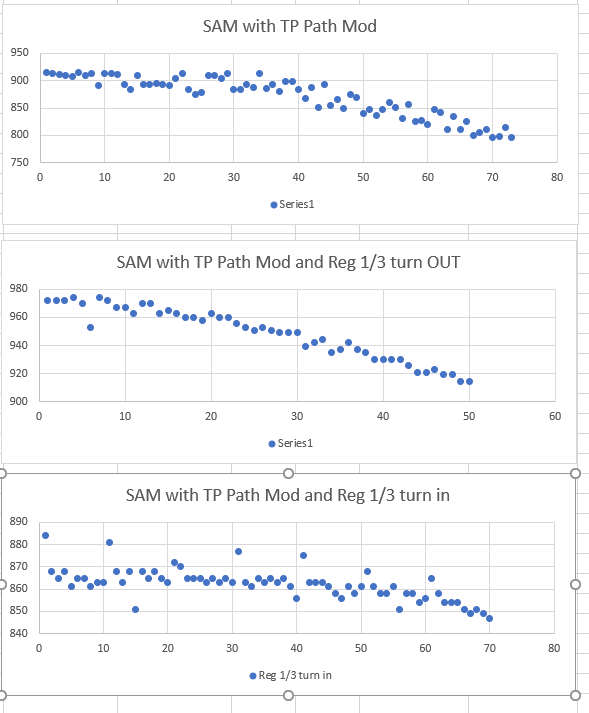

Unfortunately work got the better of me today so no time to get the reg adjusted data. Did have some time to take the last string of 70 shots from the SAM with stock reg, 3000 psi, about 8 turns in Hammer Spring, modified TP pathway as described. Will check the HS when it gets dissassembled to adjust the reg, and return the HS to this same point with the updated reg settings, for another 70 shot string as a comparison. Hopefully this is enough info for everyone on the low end, this is way below what I want and looks to be under the reg pressure. I looked at the PSI @ shot 40 when the FPS first dropped and it was a hair over the calibrated 2000 PSI. Calibrated in this case means calibrated to my cheap fill gauge, that was used to mark off the Crosman gauge aty 2k,m 2.5k, and 3k as suggested.

Raw data:

Raw data:

Upvote 0

The slight decline is what I expected to see with the adjuster 8 turns CW from full CCW. A little too much hammer spring. That will flatten out when you up the reg pressure.

Some of the shot to shot variance seems high. Do you have a graph of a full baseline string? No need for the off reg part.

Some of the shot to shot variance seems high. Do you have a graph of a full baseline string? No need for the off reg part.

Upvote 0

For those who have been following this tuning process, there's a downside to the use of heavier ammo like slugs...

It appears that the SAM can be slightly power tune modified, as we have been doing, and still shoot fast and constantly, but only as a pellet shooter. The magazine doesn't cycle slugs well. I tried 22 grain slugs today due to a gun reporting not cycling with heavy ammo. And I can confirm that it is an issue, to the point that the probe chewed up my magazine when it didn't cycle correctly, several times. I have never had an issue with Crosman 14.3 grain pellets or the heavier JSB Hades 15.89 grain pellets. It could be that the magazine clock spring needs to be heavier so it rotates into alignment at the correct point in time for when the probe cycles, but I did not experiment there. Also, the extreme spread speeds weren't as consistent with the slugs either which is another disappointment.

It appears that the SAM can be slightly power tune modified, as we have been doing, and still shoot fast and constantly, but only as a pellet shooter. The magazine doesn't cycle slugs well. I tried 22 grain slugs today due to a gun reporting not cycling with heavy ammo. And I can confirm that it is an issue, to the point that the probe chewed up my magazine when it didn't cycle correctly, several times. I have never had an issue with Crosman 14.3 grain pellets or the heavier JSB Hades 15.89 grain pellets. It could be that the magazine clock spring needs to be heavier so it rotates into alignment at the correct point in time for when the probe cycles, but I did not experiment there. Also, the extreme spread speeds weren't as consistent with the slugs either which is another disappointment.

Upvote 0

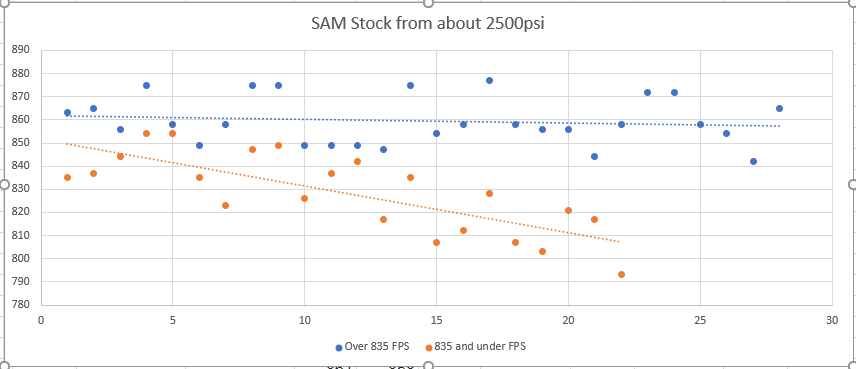

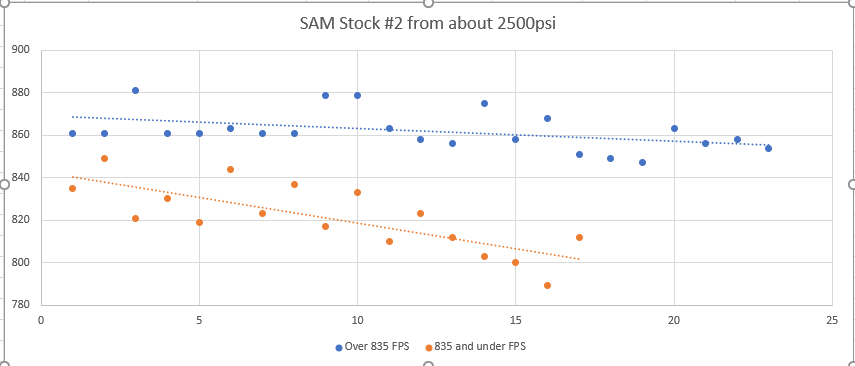

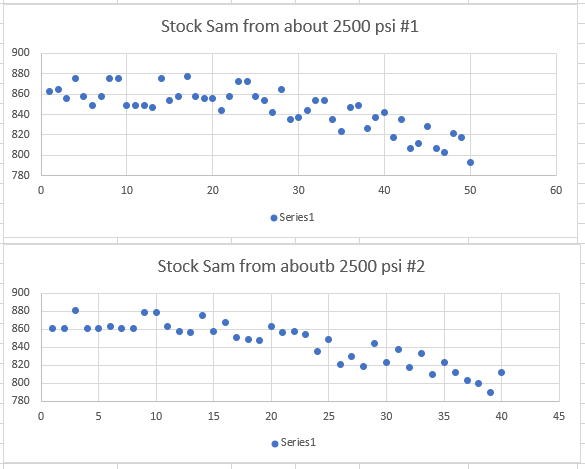

I would like to preface this with "I never said I was the sharpest tool in the shed". I truned the reg in not out. That is the first graph. I found two old shot strings using the 14.3 Crosman domes. This was from looking for the reg set point from factory, starting with very roughly 2500 psi, not the same in each test. I believe the Hammer Spring was about the same place as I had taken everything apart once prior to getting these numbers. Second and third graphs. No problems cycling in any of these tests. Now I am going to pull the thing apart again and adjust the reg in the ahem other direction... one more time.

Any issues with a little dab of blue loctite on the screws that go into the valve and hammer on final assembly? I am trying to be pretty gentle here but things are coming loose pretty quickly. Also, will blue loctite keep the nylon regulator adjustment in place and allow m,e to break it free? For testing im not putting anything on it and will visually check if it is moving.

Any issues with a little dab of blue loctite on the screws that go into the valve and hammer on final assembly? I am trying to be pretty gentle here but things are coming loose pretty quickly. Also, will blue loctite keep the nylon regulator adjustment in place and allow m,e to break it free? For testing im not putting anything on it and will visually check if it is moving.

Upvote 0

Grerat point about heavier pellets and slugs. The 18.1 gr JSB domes cycled fine, but I did notice a little dent or two inside the magazine I was shooting with so that may be close to the limit of what will work. 25.5gr JSB would not run a full mag without a failure to feed and the mag was chewed up a little from 10 rounds.

Also, a thought about the shot variance. The pressure tube is warm from filling at the first shot, but cold at the end. For the most part shots have a full second between. Except the first lo0w FPS shot on the 1/3 turn in graph, that was immediately following the previous shot. interesting that the high outliers are each mag change. I tried to pause while shooting for as long as the mag change took but that had no effect.

Also, a thought about the shot variance. The pressure tube is warm from filling at the first shot, but cold at the end. For the most part shots have a full second between. Except the first lo0w FPS shot on the 1/3 turn in graph, that was immediately following the previous shot. interesting that the high outliers are each mag change. I tried to pause while shooting for as long as the mag change took but that had no effect.

Upvote 0

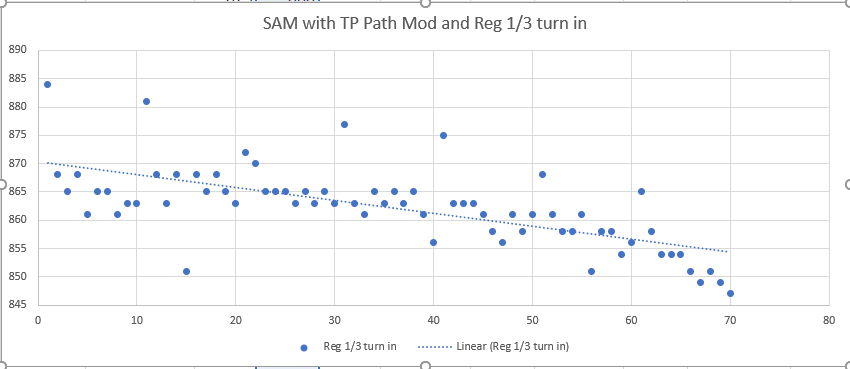

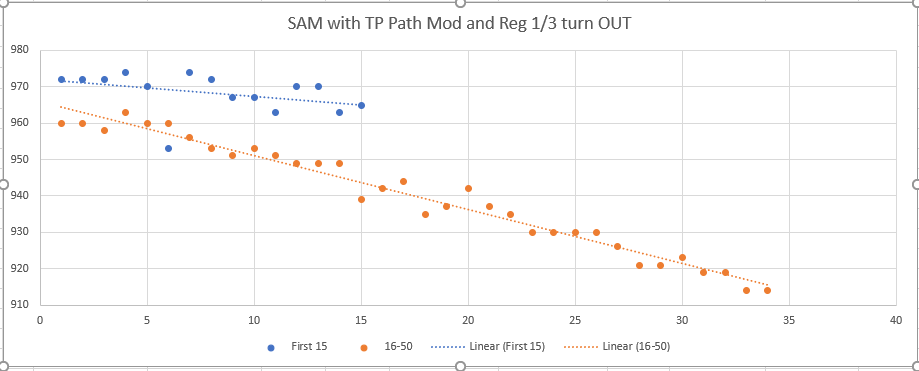

Regulator about 1/3 turn OUT... from 3000 psi using 14.3gr.

I took the first 15 as a ballpark of the regulated shots and the rest as off. Hammer Spring should be the same. Did not take reg out to inspect but will try another string.

Shot 1 mag of 18.1:

Shot count: 10

Low: 849

Hi: 868

Avg: 860

Spread: 19

STD Dev: 4.9

Tried another mag of 25.5 and grabbed a tin of REDESIGNED by mistake, failure to load every other shot. The original 25.5 pellets were the standard 25.5 not the redesigned but not sure why that would have any impact.

Still at 30FPE. Curious about using an aftermarket reg with gauge port to increase plenum volume(instead of moving the stock and drilling another vent), increase Valve Exhaust port and Transfer Port size a little further (maybe drilling part of the way through the Transfer Port so there is less of a bottleneck before the bolt/probe thing) and adjusting the Hammer Spring. I should probably pull the outlier pellet out of the regulated string but wanted to show the raw stuff and let the folks that know this make some assessments. Does the decreasing trend from the early regulated shots indicate too much hammer spring still?

I have not tried to apply more bolt return spring force but that might be worth a few FPS but not sure going down that road is worth it, compared to using a different reg for increased plenum volume and maybe opening part of the air path a little more. Going further with the valve could change the hammer cocking mechanism, but so far the little volume increases seem to have minimal impact, but I cant really test how close to not getting the hammer re-cocked this is. Would more spring tension would provide a aimilar effect as decreasing the air pressure on the valve to test that before drilling?

I took the first 15 as a ballpark of the regulated shots and the rest as off. Hammer Spring should be the same. Did not take reg out to inspect but will try another string.

Shot 1 mag of 18.1:

Shot count: 10

Low: 849

Hi: 868

Avg: 860

Spread: 19

STD Dev: 4.9

Tried another mag of 25.5 and grabbed a tin of REDESIGNED by mistake, failure to load every other shot. The original 25.5 pellets were the standard 25.5 not the redesigned but not sure why that would have any impact.

Still at 30FPE. Curious about using an aftermarket reg with gauge port to increase plenum volume(instead of moving the stock and drilling another vent), increase Valve Exhaust port and Transfer Port size a little further (maybe drilling part of the way through the Transfer Port so there is less of a bottleneck before the bolt/probe thing) and adjusting the Hammer Spring. I should probably pull the outlier pellet out of the regulated string but wanted to show the raw stuff and let the folks that know this make some assessments. Does the decreasing trend from the early regulated shots indicate too much hammer spring still?

I have not tried to apply more bolt return spring force but that might be worth a few FPS but not sure going down that road is worth it, compared to using a different reg for increased plenum volume and maybe opening part of the air path a little more. Going further with the valve could change the hammer cocking mechanism, but so far the little volume increases seem to have minimal impact, but I cant really test how close to not getting the hammer re-cocked this is. Would more spring tension would provide a aimilar effect as decreasing the air pressure on the valve to test that before drilling?

Upvote 0

Because of the declining string, looking at the first mag from 3K. Looks like you gained 50-60fps with the 14.3g pellets, with the set-point increase. The declining string will also make it harder to determine where the set-point is. Can you plot as contiguous string?. The split just makes it harder to understand. At least for me. Having gauge reading every 4 shots (best estimate you can).

Yes, I think you could use a Huma instead of drilling vent hole. Just make sure you give it a few seconds between each shot. Test it thoroughly before doing any rapid fire. I would expect to have some declining power during rapid. Then again, don't know if we have any rapid oem data to compare to.

FWIW: I have tried a CARM mag and it will not work even with stock gun and 14.3 crosman domes. Many mis-fires. I had hopes that the more cylindracal chambers would work better than the narrow wheel.

Yes, I think you could use a Huma instead of drilling vent hole. Just make sure you give it a few seconds between each shot. Test it thoroughly before doing any rapid fire. I would expect to have some declining power during rapid. Then again, don't know if we have any rapid oem data to compare to.

FWIW: I have tried a CARM mag and it will not work even with stock gun and 14.3 crosman domes. Many mis-fires. I had hopes that the more cylindracal chambers would work better than the narrow wheel.

Upvote 0

Got it, thanks for the feedback. It will take me a bit to get the PSI added, I dont have great resolution on that. Here is everything done with 14.3 gr so far, hopefully a clearer view. Except the two stck tests everything was done with a fresh fill to 3000 psi.

About the mags, I took a drill bit and routed out the smashed plastic on the first SAM mag I beat up. The fins are a bit thin where they were smashed but the mag seems to function fine again. That mag was not for this testing.

About the mags, I took a drill bit and routed out the smashed plastic on the first SAM mag I beat up. The fins are a bit thin where they were smashed but the mag seems to function fine again. That mag was not for this testing.

Upvote 0

So far all the testing here has been with at least a one-one thousand count between shots unless noted otherwise. I did run a couple mags rapid fire stock and thought the FPS dropped a bit but dont have that recorded. Ill try another mag rapid fire as it is now and post that.

Upvote 0

The last graph that 1st shot after mag change, stands out. That can be something with the Tbolt release/assist, or maybe reg creep. It's not as prominent in the other graphs.

For the next test, are you thinking of going higher on the oem? or switching out for a huma?

My thought is to go 1/3 more on the oem reg. If you level out the current string by dropping down on the hammer spring, it will be around 920fps w/14.3g.

PS: thx for the graph change.

For the next test, are you thinking of going higher on the oem? or switching out for a huma?

My thought is to go 1/3 more on the oem reg. If you level out the current string by dropping down on the hammer spring, it will be around 920fps w/14.3g.

PS: thx for the graph change.

Upvote 0

Glad the graphs show you whats going on! The mag change thing is interesting. I was wondering if the pellet/bolt probe was not seating all the way with semi auto cycling. Every mag change I would push the assist but never saw that FPS change before. I thought it might be reg recovery time but let the rifle rest longer than the mag change time with no effect. I am still using my printed assist button. I can swap this back though. The reg seems about right at 1/3 turn over OEM to get about 20 regulated shots. Seems like your ballaprk of 200 psi/quarter turn was right on from what I have seen so far. Might be good to know what happens turned up further but I would be turning it back down to here to get 2 mags full to stay. With the pressure up that buffered sound from a shot on an empty mag has changed tone to a much sharper pop. It seems like more pressure would only smack the bolt into the homemade forward assist. I really dont want to replace the bolt/probe (and drill out the breech) if I dont have to.

Here is what I am thinking but am open to suggestions.

Try a mag of the 18gr with forward assist pushed for curiosity...

Try a little more pressure from Regulator adjustment.

Try to open the valve and valve side of the TP more (I got a spare valve so that is easily reversible) to see what can be done for free with the OEM parts.

I have a reg with a gauge port on the way so that test will be coming. Losing the ability to see tube pressure bugs me but it looks like the fill port with gauge from Huma would fix that.

Thank you again for all the help so far!

Here is what I am thinking but am open to suggestions.

Try a mag of the 18gr with forward assist pushed for curiosity...

Try a little more pressure from Regulator adjustment.

Try to open the valve and valve side of the TP more (I got a spare valve so that is easily reversible) to see what can be done for free with the OEM parts.

I have a reg with a gauge port on the way so that test will be coming. Losing the ability to see tube pressure bugs me but it looks like the fill port with gauge from Huma would fix that.

Thank you again for all the help so far!

Upvote 0

Interesting experiment... the crosman reg fills fast and is accurate. It seems like it is actually more accurate flowing fast. Maybe all regs are like this? Im a noob...

2 strings at with current settings at about 2800 psi starting, 14.3 gr, full rapid fire, 0.1-0.2 seconds between shots per the chrony:

String one:

Shot count: 10

Low: 942

Hi: 951

Avg: 947

Spread: 9

STD Dev: 2.8

String two:

Shot count: 10

Low: 946

Hi: 953

Avg: 948

Spread: 7

STD Dev: 2.8

Also, more pressure on the assist spring did nothing (or a little less than nothing). The first 5 are assist pushed, the second 5 without assist:

Shot count: 10

Low: 844

Hi: 863

Avg: 858

Spread: 19

STD Dev: 5.3

844

858

858

858

856

863

858

861

861

861

Going to crank up the reg a little and test. Then maybe try the valve stuff unless i hear that would be a bad idea... I was looking at the Lane regulator website marauder manual for clues about their recommended valve mods:

https://drive.google.com/open?id=1sQFIWqITcn4TA5nMTR-EEdDjx0Rj38KY

2 strings at with current settings at about 2800 psi starting, 14.3 gr, full rapid fire, 0.1-0.2 seconds between shots per the chrony:

String one:

Shot count: 10

Low: 942

Hi: 951

Avg: 947

Spread: 9

STD Dev: 2.8

String two:

Shot count: 10

Low: 946

Hi: 953

Avg: 948

Spread: 7

STD Dev: 2.8

Also, more pressure on the assist spring did nothing (or a little less than nothing). The first 5 are assist pushed, the second 5 without assist:

Shot count: 10

Low: 844

Hi: 863

Avg: 858

Spread: 19

STD Dev: 5.3

844

858

858

858

856

863

858

861

861

861

Going to crank up the reg a little and test. Then maybe try the valve stuff unless i hear that would be a bad idea... I was looking at the Lane regulator website marauder manual for clues about their recommended valve mods:

https://drive.google.com/open?id=1sQFIWqITcn4TA5nMTR-EEdDjx0Rj38KY

Upvote 0

Currently, your porting and regulator mods and 14.3 grain pellet speeds are nearly identical to mine. If you go further, here's what I've found...

I've read the ports of other regulated .22 pcp's being opened to the 0.160"-0.169"" diameter to run super fast and efficient with much heavier slugs. Opening the ports up much over that and velocity and efficiency goes down (wasted air after the shot) unless the valve closes fast too. But, the SAM runs the bolt/probe on that wasted air, so...

I'm thinking that if you open the valve port and transfer port more (to 0.166") the air will flow more and you will likely gain a decent amount of speed. But with a low reg pressure it is probably not cycling the heavier ammo, so that needs turned up more as well (to get the "bounce" of air to keep the bolt/probe open longer so the magazine cycles all the way). So, with the port size increased even further, reg pressure increased another 1/4 turn, the hammer may still "bounce" to cycle the heavier lead.

As far as going "back to stock" goes, even with the valve port opened up to 0.166", replacing the small aluminum transfer port that is drilled at 0.156" can be used to regulate air flow between the barrel and tube assembly. However, because the barrel port would have to be opened up to the same diameter to make this all work as well, there's no going back there.

I've read the ports of other regulated .22 pcp's being opened to the 0.160"-0.169"" diameter to run super fast and efficient with much heavier slugs. Opening the ports up much over that and velocity and efficiency goes down (wasted air after the shot) unless the valve closes fast too. But, the SAM runs the bolt/probe on that wasted air, so...

I'm thinking that if you open the valve port and transfer port more (to 0.166") the air will flow more and you will likely gain a decent amount of speed. But with a low reg pressure it is probably not cycling the heavier ammo, so that needs turned up more as well (to get the "bounce" of air to keep the bolt/probe open longer so the magazine cycles all the way). So, with the port size increased even further, reg pressure increased another 1/4 turn, the hammer may still "bounce" to cycle the heavier lead.

As far as going "back to stock" goes, even with the valve port opened up to 0.166", replacing the small aluminum transfer port that is drilled at 0.156" can be used to regulate air flow between the barrel and tube assembly. However, because the barrel port would have to be opened up to the same diameter to make this all work as well, there's no going back there.

Upvote 0

Thank you for that! You were exactly right before, going back to stock completely is not what I want. And you bring up another great point, it is still possible to put the more restrictive stock TP in there.

Another development here. When I pulled the reg out, it was at almost 2/3 turn out, it moved. This is exactly what FuzzyGrub said would happen without loctite. Unfortunately, it is not clear when this happened over the last sets of tests. The numbers being consistent with yours is really helpful indicating we are in reproducible territory. The first string and the last string (when the reg had likely already moved) are not different enough to make turning it up further seem worthwhile. Any higher and it would be fewer regulated shots than I wanted, 2 magazines ideally. With the reg already at 2/3 (so now maybe 2500 PSI ballpark) it looks like the 2 options remaining are bigger plenum and bigger valve/ports. getting a 25gr pellet going 860 fps would be the 40 fpe I was looking for initially. It seems like getting 21-22 grain pellets going 860 at 35 fpe seems more reasonable now. One of the 11/64 drill bits I have measures at 0.167". So I am going to try to do half of the TP air path with that and be optimistic. I dont mind trading efficiency and shot count for a little more power.

I looked at the bolt probe and dont want to reduce the size and strength much more if at all. It still seems worthwhile to test if there is any gain to be had by opening the rest of TP air path and leaving the bolt probe as the final bottleneck. Getting most of the path opened up to 0.167" might be half assed, but if that gets me from 30 to 32.5 fpe and the larger plenum gets up to 35, cycling well, that is good enough. Hopefully increasing spring force on the valve will not be necessary. I am also considering expanding the air path inside the valve stem seat, but this might ruin the seal so I will try the TP path first.

I dont really understand the bolt cycling situation. Same for the separate hammer bounce-cocking. I just wrote and then deleted a novel here trying to think through how the bolt magazine pellet weight and air pressure timing is all balanced in writing. Long story short I dont want to spend time going down that hole. Same thing for the hammer bounce cocking. Call me lazy, you would be right... if someone figures out a good recipe for making all the changes to get good cycling with 25 gr or heavier pellets or slugs (like the diablo redesign that work extremely well in the Huben semi auto) fantastic. That was my initial goal but seems past the point of diminishing returns. Making this a 2 drill bit process still seems reasonable to try, even if it is a waste. Or if expanding inside the valve seat a 3 drill bit process. But that is it,3 drill bits max!!! If I am off my rocker here please let me know! Im always the last to know when that happens.

Otherwise ill post some numbers from the enlarged TP path with the reg (still) at about 2/3 turn out tomorrow.

Another development here. When I pulled the reg out, it was at almost 2/3 turn out, it moved. This is exactly what FuzzyGrub said would happen without loctite. Unfortunately, it is not clear when this happened over the last sets of tests. The numbers being consistent with yours is really helpful indicating we are in reproducible territory. The first string and the last string (when the reg had likely already moved) are not different enough to make turning it up further seem worthwhile. Any higher and it would be fewer regulated shots than I wanted, 2 magazines ideally. With the reg already at 2/3 (so now maybe 2500 PSI ballpark) it looks like the 2 options remaining are bigger plenum and bigger valve/ports. getting a 25gr pellet going 860 fps would be the 40 fpe I was looking for initially. It seems like getting 21-22 grain pellets going 860 at 35 fpe seems more reasonable now. One of the 11/64 drill bits I have measures at 0.167". So I am going to try to do half of the TP air path with that and be optimistic. I dont mind trading efficiency and shot count for a little more power.

I looked at the bolt probe and dont want to reduce the size and strength much more if at all. It still seems worthwhile to test if there is any gain to be had by opening the rest of TP air path and leaving the bolt probe as the final bottleneck. Getting most of the path opened up to 0.167" might be half assed, but if that gets me from 30 to 32.5 fpe and the larger plenum gets up to 35, cycling well, that is good enough. Hopefully increasing spring force on the valve will not be necessary. I am also considering expanding the air path inside the valve stem seat, but this might ruin the seal so I will try the TP path first.

I dont really understand the bolt cycling situation. Same for the separate hammer bounce-cocking. I just wrote and then deleted a novel here trying to think through how the bolt magazine pellet weight and air pressure timing is all balanced in writing. Long story short I dont want to spend time going down that hole. Same thing for the hammer bounce cocking. Call me lazy, you would be right... if someone figures out a good recipe for making all the changes to get good cycling with 25 gr or heavier pellets or slugs (like the diablo redesign that work extremely well in the Huben semi auto) fantastic. That was my initial goal but seems past the point of diminishing returns. Making this a 2 drill bit process still seems reasonable to try, even if it is a waste. Or if expanding inside the valve seat a 3 drill bit process. But that is it,3 drill bits max!!! If I am off my rocker here please let me know! Im always the last to know when that happens.

Otherwise ill post some numbers from the enlarged TP path with the reg (still) at about 2/3 turn out tomorrow.

Upvote 0

The 0.160"-0.170" porting is well established with aftermarket regulation on standard Mrods. One key difference is this, uses a flow thru bolt vs a pin probe. Measure the ID of the tip of the probe where it will contact the pellet. See what number drill that just fits into it, and measure that. You indicated you do not plan to open that further, and I agree. Calculate the cross-sectional area. For each step back, make sure you have the same cross-sectional area or more ideally, slightly more. Say 5-10%. The slight increase should happen at each step. Next step back is the inlet hole to probe. Then barrel port, transfer port, valve exhaust, valve pocket. The valve pocket requires subtracting the cross-section of the poppet stem. Do all the calculations so you know how much has to come off each of these and if you have the capability to do so. If not, recalculate based on that restriction.

Not sure what is driving only using one, two, three drill bits???

Anytime the reg is below set point, the adjuster can easily turn. This includes installation, pressurization, any time it was shot below set-point, depressurization, and removal. If it moved in between shot strings, we should have seen the change. Your 1/3 in numbers were fairly proportional to the 1/3 out. I wouldn't assume you have shot strings with 2/3 out.

Not sure what is driving only using one, two, three drill bits???

Anytime the reg is below set point, the adjuster can easily turn. This includes installation, pressurization, any time it was shot below set-point, depressurization, and removal. If it moved in between shot strings, we should have seen the change. Your 1/3 in numbers were fairly proportional to the 1/3 out. I wouldn't assume you have shot strings with 2/3 out.

Upvote 0

Excellent! Once again that is great insight. The drill bit thing is mostly me being silly but kind of a “this is not too complicated” statement. The numbers looked consistent so I was baffled about when the reg had moved. The adjustment seemed tight like a nylon locknut without pressure, but that is not the same repeatedly crossing the set point filling and shooting.

I have some numbers on the assembly with the reg turned up and the stepwise increases through that airflow path from the valve pocket but it seems like the reg adjuster is moving. Or spring locked, or a combination. Here is a string with a couple failures to cycle. The shot count should have been 40, the second number was probably two pellets. The second string below was refilled and looks like the regulator set point moved. I’ll pull it apart, see how things look, and loctite the reg adjuster, exactly as you said from the beginning. I am changing my New Years resolution to just listen to good advice.

Thanks again for the information this continues to be critically helpful! I’ll get more data posted today with some loctite on the reg.

Shot count: 37

Low: 703

Hi: 1042

Avg: 942

Spread: 339

STD Dev: 51.0

1042

703

993

988

1004

984

981

967

972

967

970

902

965

965

963

958

958

953

951

944

944

942

939

942

932

930

928

930

926

923

919

916

916

912

914

905

900

Shot count: 30

Low: 898

Hi: 970

Avg: 927

Spread: 72

STD Dev: 10.9

970

898

944

923

923

921

921

923

923

923

928

921

916

923

928

923

930

926

932

930

932

923

930

926

928

930

928

928

928

921

I have some numbers on the assembly with the reg turned up and the stepwise increases through that airflow path from the valve pocket but it seems like the reg adjuster is moving. Or spring locked, or a combination. Here is a string with a couple failures to cycle. The shot count should have been 40, the second number was probably two pellets. The second string below was refilled and looks like the regulator set point moved. I’ll pull it apart, see how things look, and loctite the reg adjuster, exactly as you said from the beginning. I am changing my New Years resolution to just listen to good advice.

Thanks again for the information this continues to be critically helpful! I’ll get more data posted today with some loctite on the reg.

Shot count: 37

Low: 703

Hi: 1042

Avg: 942

Spread: 339

STD Dev: 51.0

1042

703

993

988

1004

984

981

967

972

967

970

902

965

965

963

958

958

953

951

944

944

942

939

942

932

930

928

930

926

923

919

916

916

912

914

905

900

Shot count: 30

Low: 898

Hi: 970

Avg: 927

Spread: 72

STD Dev: 10.9

970

898

944

923

923

921

921

923

923

923

928

921

916

923

928

923

930

926

932

930

932

923

930

926

928

930

928

928

928

921

Upvote 0

I forgot to mention that the rapid fire did look good. Makes me think that there is some reg creep. If there was a gauge on the plenum, we'd probably see it.

At what point did the misfires come? Beginning of a mag? Last few shots of a mag? Early, middle, or end of string?

At what point did the misfires come? Beginning of a mag? Last few shots of a mag? Early, middle, or end of string?

Upvote 0