*Updated with chronograph/efficiency data on 09/06/2021 - See below

Hey folks,

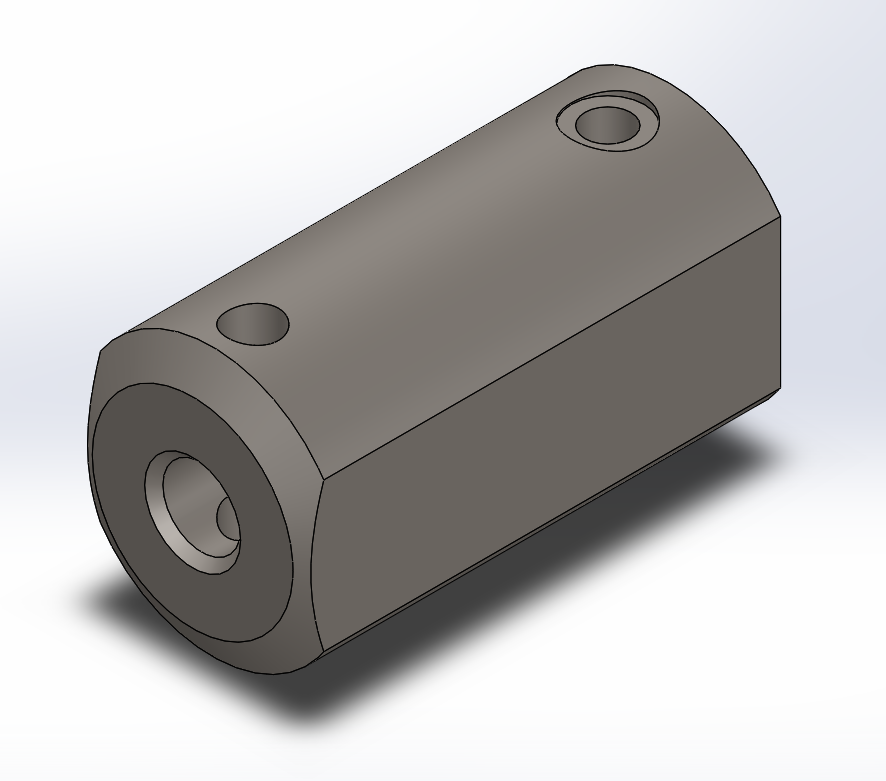

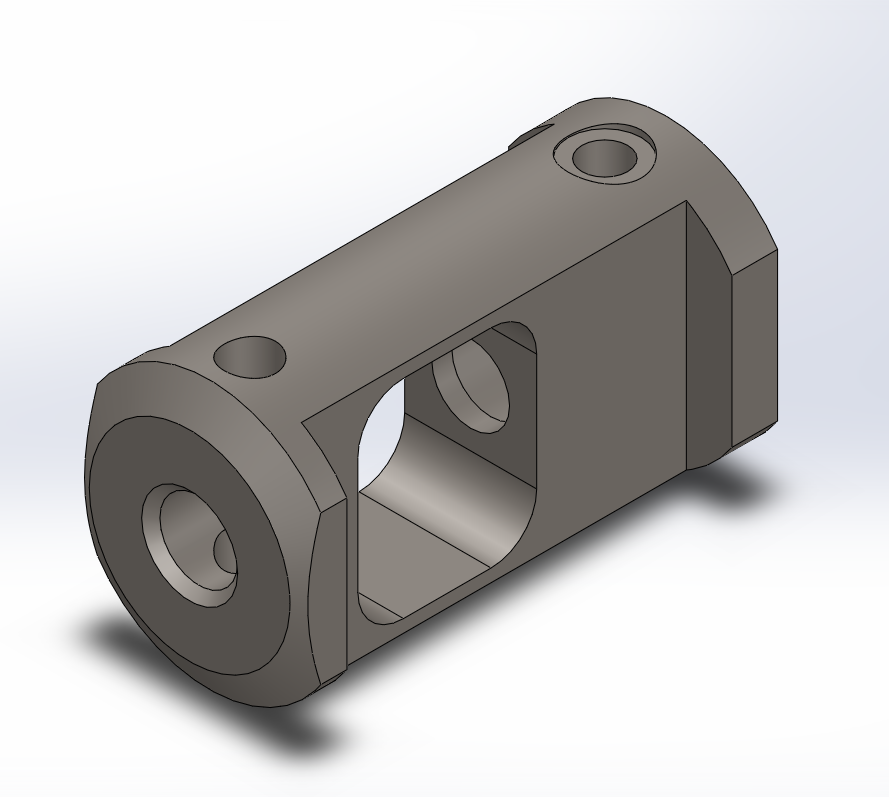

Hadn't seen a lightweight hammer for the Marauder Pistol that was available for regular sale. So I decided to CAD one up and estimate what it would take to "lightweight" the OEM part in a simple, reasonable manner. Long story short, after some iterations in Solidworks, the estimate hovered just under 50% reduction in weight (55g in OEM form, 27g machined). Since the result looked decent, and an OEM part is ~$18 to your door, I ordered one to cut up on the mini mill.

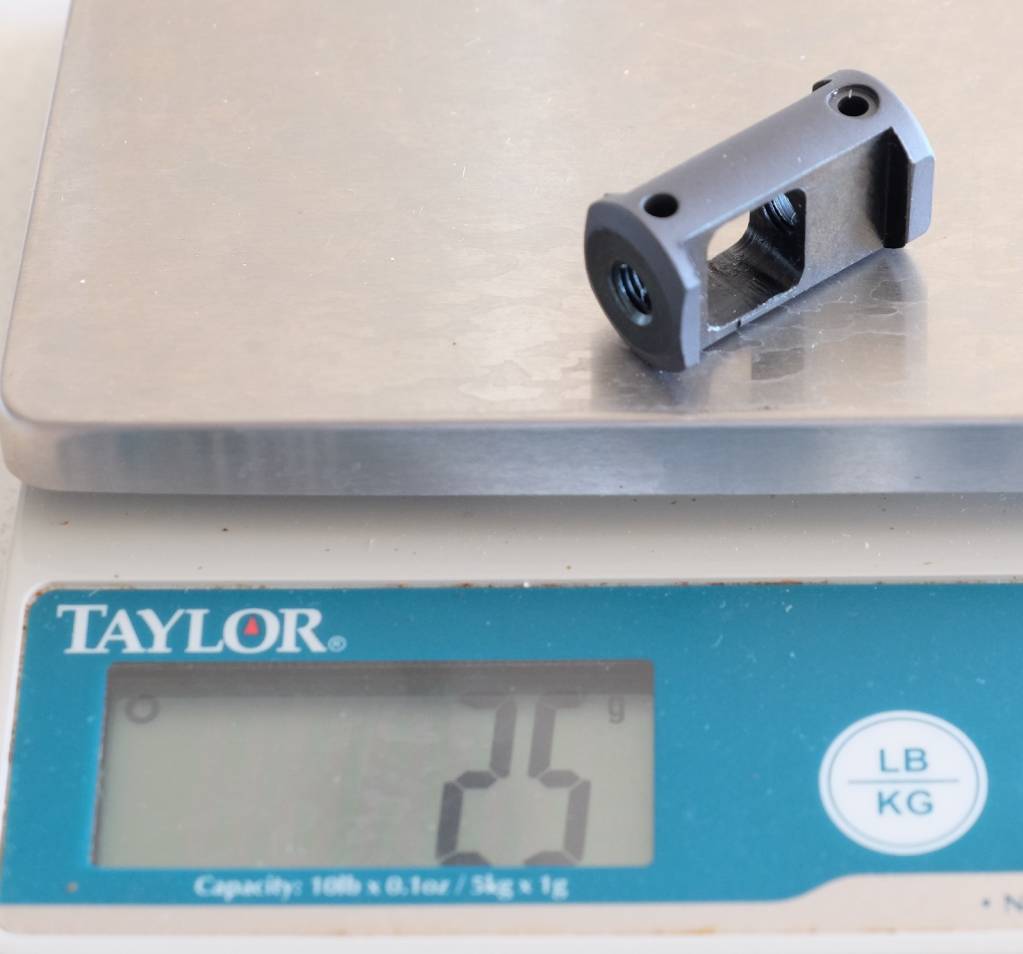

Final result of machining: OEM part weight - 54g; Machined - 25g; ~54% weight reduction. Retains all OEM functionality and interface geometry.

For comparison, a 6061 Aluminum version of the OEM hammer geometry would weigh ~19g, compared to 54g for the steel part.

Wanted to try this to see if I could net the highest shot-count, lower power tune when regulated. Plan to update this when I've done some Chrony testing.

Figured others may find the info helpful in their tuning efforts. A similar result could be achieved with a hand drill, a set of metal files, and a steady hand (angle grinder too, if you're feeling fancy). Took about 3 hours with the mini-mill all said and done but I don't claim to be remotely close to a competent machinist with adequate tools... Thankfully the steel is not hardened, and cuts well with HSS tools.

Thanks for reading!

OEM: Machined:

Hey folks,

Hadn't seen a lightweight hammer for the Marauder Pistol that was available for regular sale. So I decided to CAD one up and estimate what it would take to "lightweight" the OEM part in a simple, reasonable manner. Long story short, after some iterations in Solidworks, the estimate hovered just under 50% reduction in weight (55g in OEM form, 27g machined). Since the result looked decent, and an OEM part is ~$18 to your door, I ordered one to cut up on the mini mill.

Final result of machining: OEM part weight - 54g; Machined - 25g; ~54% weight reduction. Retains all OEM functionality and interface geometry.

For comparison, a 6061 Aluminum version of the OEM hammer geometry would weigh ~19g, compared to 54g for the steel part.

Wanted to try this to see if I could net the highest shot-count, lower power tune when regulated. Plan to update this when I've done some Chrony testing.

Figured others may find the info helpful in their tuning efforts. A similar result could be achieved with a hand drill, a set of metal files, and a steady hand (angle grinder too, if you're feeling fancy). Took about 3 hours with the mini-mill all said and done but I don't claim to be remotely close to a competent machinist with adequate tools... Thankfully the steel is not hardened, and cuts well with HSS tools.

Thanks for reading!

OEM: Machined: