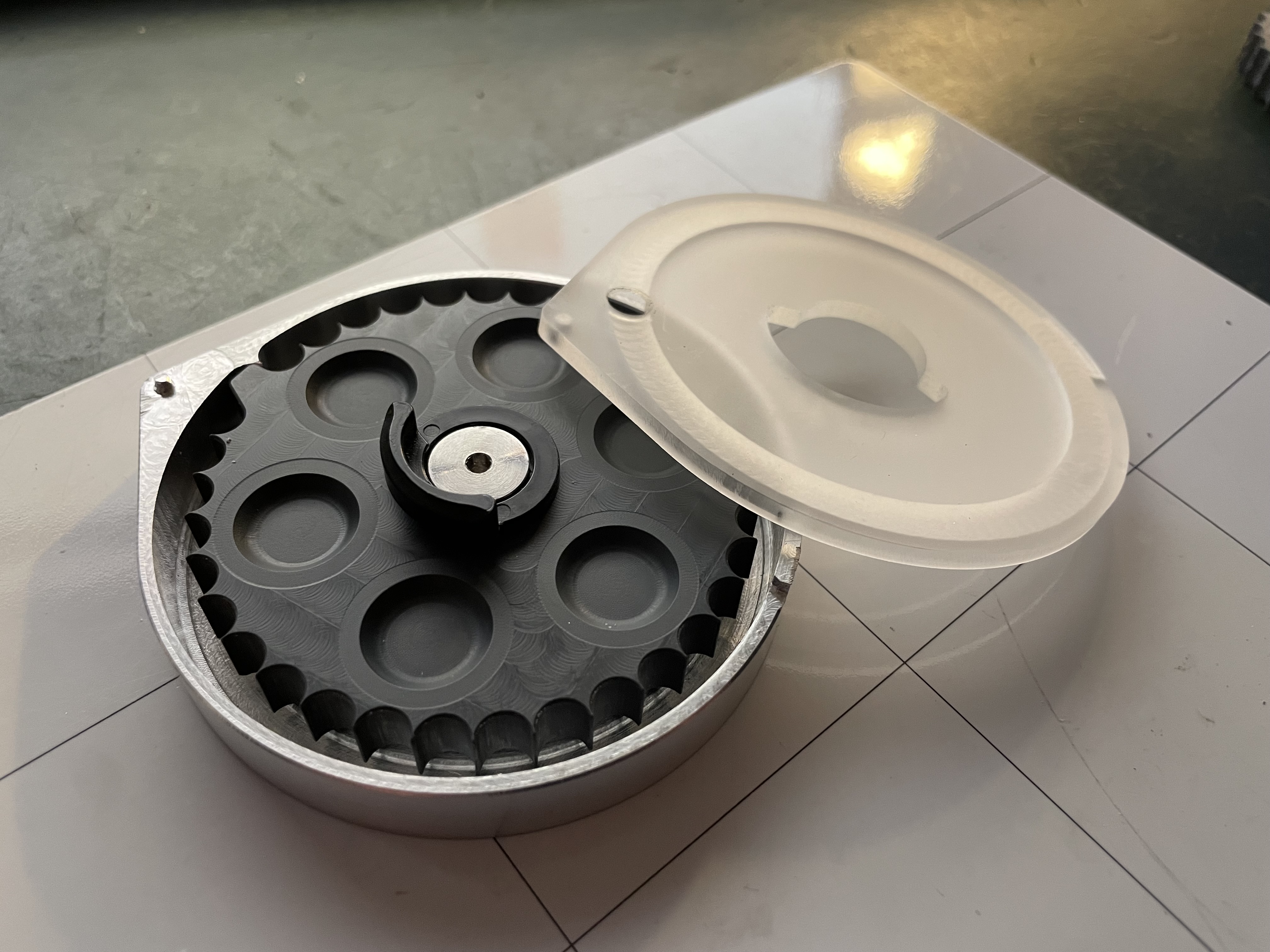

Still some small things to tweak but it cycles reliably. Fits up to 12.2 mm long slugs so it handles 40 grainers with some room to spare. The housing is made from 6082-T6, the rotating pellet-holdy thing is made from delrin (which is a dream to machine) and the top cover is made from perspex. The locket is standard FX parts (for now). All cnc-machined, no 3d-printed parts.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Made a aluminum 34 shot .22 M3 mag

- Thread starter Der_Berend

- Start date

I will, once I figure out something for the locket and get the production under control to a degree where I don't have to spend an hour with skotch-brite just to get the thing to cycle reliably. Once I get to the point where I can make at least 3 of them a day it becomes viable for me to sell some.Congratulations !!!!

Now, make more and sell them !!

Upvote 0

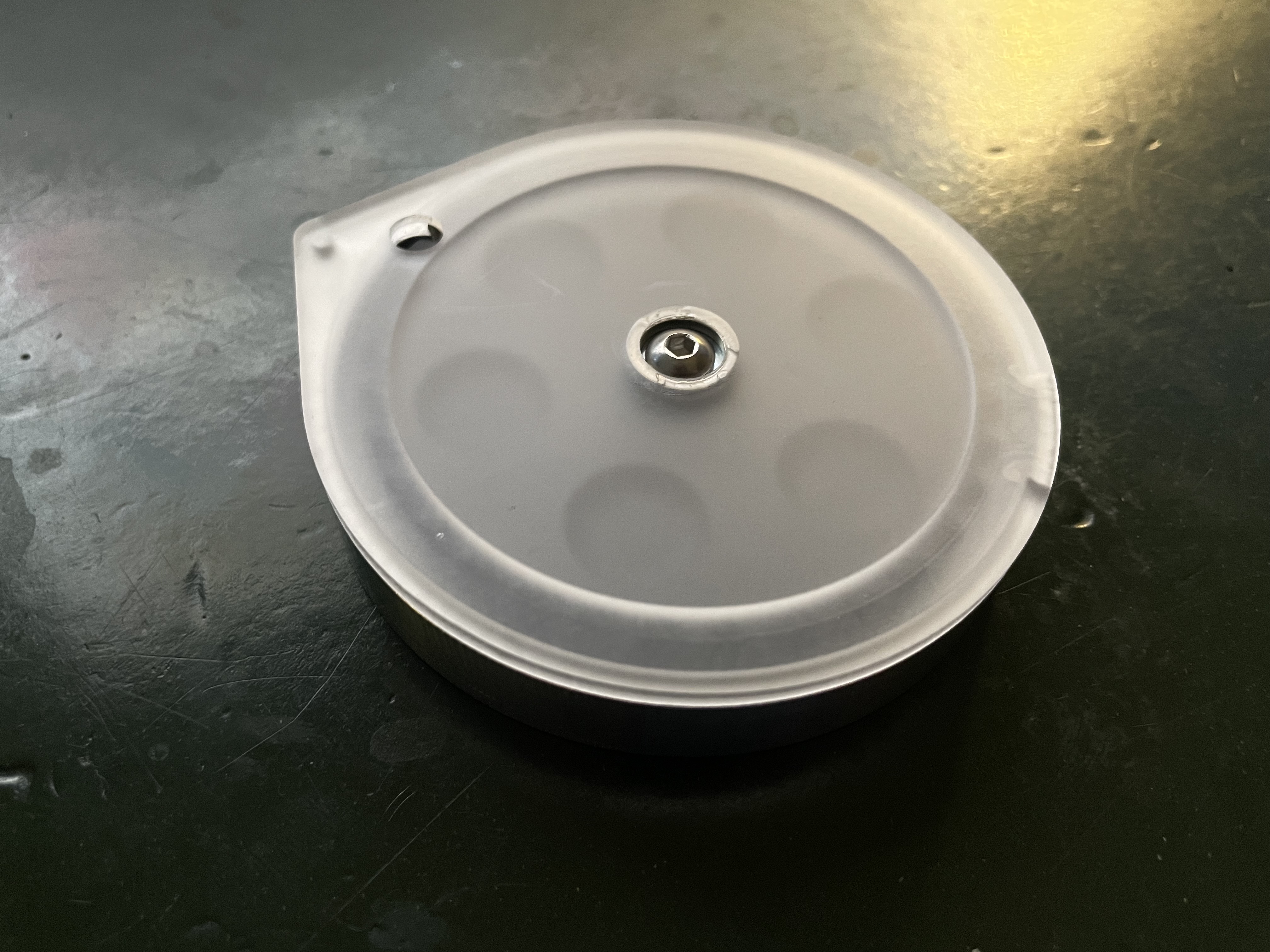

Update: no more FX parts! Over the last few weeks, I've gone through another couple of iterations and I'm now almost at the point where I feel comfortable doing a small production run if enough people are interested. Going to mill the recesses in the cover just a few hundredths of a millimeter wider so that they don't require any hand finishing anymore (almost there but I had to file some edges just a tiny bit here and there), and I might tweak the pellet backstop around the feeding hole just a little bit: everything from ZAN 36 grain slugs to H&N FTT's cycles perfectly, but JSB jumbo heavy exacts don't cycle as reliably as I want them. Might just be a bad tin of pellets though: it sprung open during shipping and the tin had a big ol' ding in the side. Called the shop about it and a new tin is on its way.

The cover now firmly snaps in place using a beefy magnet: 1.3kg (2.9 lbf) of holding. Loaded full of ZAN 36 grain slugs, I had to absolutely yank it back holding it upside-down before the cover would come off. The cassette (also known as the rotating pellet-holdy thing) is rotated using a beefed up version of the spring you find in the stock magazines, only without the hassle of losing the little ball bearings and springs whenever you need to assemble/disassemble the magazine if you want to change your spring pre-load.

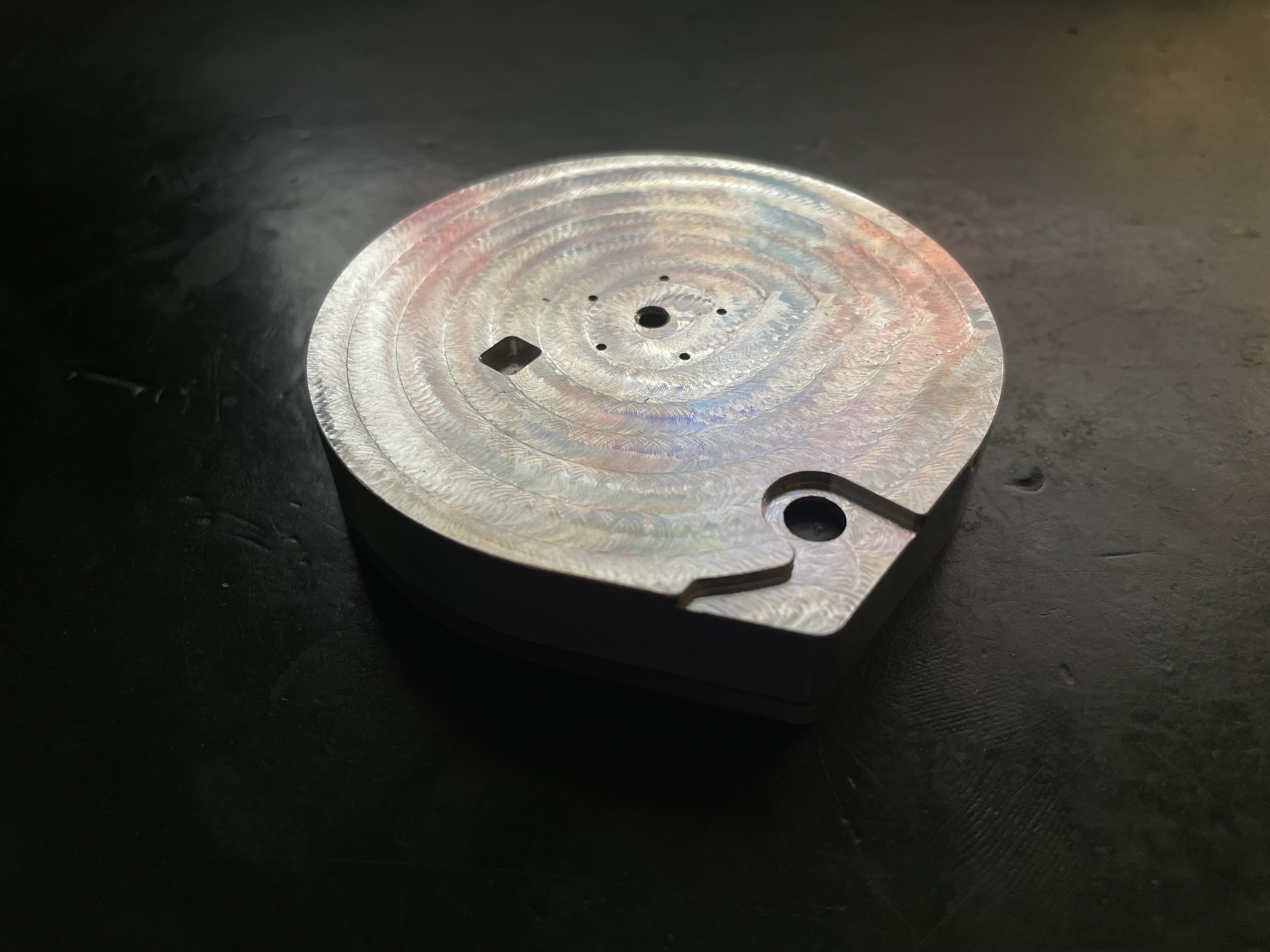

For you amusement: below is the last iteration before this one: I thought a torque spring would allow for more even torque over a rotation. Turns out this type of spring is not at all suited for my intended purpose: you could wind it up about 100 degrees before the force became absolutely ridiculous and the spring alone doubled the (already not especially low) cost of the bill of materials. At least it looked pretty! Also, the tiny magnets were not enough to hold the cover in place reliably. And installing them turned into a nightmare of frustration and superglue in a hurry.

So, there you go. A 34 shot CNC machined aluminum FX Impact magazine, magnetic cover, shoots up to 40 grain slugs. Only took about 15 tries and the better part of a semester's worth of skipped lectures, but the thing is now (almost) ready.

The cover now firmly snaps in place using a beefy magnet: 1.3kg (2.9 lbf) of holding. Loaded full of ZAN 36 grain slugs, I had to absolutely yank it back holding it upside-down before the cover would come off. The cassette (also known as the rotating pellet-holdy thing) is rotated using a beefed up version of the spring you find in the stock magazines, only without the hassle of losing the little ball bearings and springs whenever you need to assemble/disassemble the magazine if you want to change your spring pre-load.

For you amusement: below is the last iteration before this one: I thought a torque spring would allow for more even torque over a rotation. Turns out this type of spring is not at all suited for my intended purpose: you could wind it up about 100 degrees before the force became absolutely ridiculous and the spring alone doubled the (already not especially low) cost of the bill of materials. At least it looked pretty! Also, the tiny magnets were not enough to hold the cover in place reliably. And installing them turned into a nightmare of frustration and superglue in a hurry.

So, there you go. A 34 shot CNC machined aluminum FX Impact magazine, magnetic cover, shoots up to 40 grain slugs. Only took about 15 tries and the better part of a semester's worth of skipped lectures, but the thing is now (almost) ready.

Upvote 0

Fellow toolmaker/machinist also ( going on 32 years) .. machining your own accessories yourself gets addicting

Well done..!!

Well done..!!

Upvote 0

Indeed. And very expensiveFellow toolmaker/machinist also ( going on 32 years) .. machining your own accessories yourself gets addicting

Well done..!!

Upvote 0

Update: tweaked the design just a little more and now the JSB exacts cycle, save for the occasional hang-up because half of the skirts in these two tins are bent to all hell. Spinny thing is now done. Made from delrin, which feels and looks a lot nicer than the PVC ones on previous versions. The cover on the final version will be made from clear polycarbonate, which is still on its way but I couldn't wait and made one from what I had laying around; the way it snaps into place with the ring magnet has a high giggle factor.

Upvote 0

Thanks! How steep they will be depends on how many people are interested unfortunately. The last few months have been a good lesson into economics of scale. I want to have them anodised for the finishing touch but that’s only viable from like 10+ pieces due to minimum order sizes. The main issue rn is that it takes me about a day each. Trying to keep the final cost below €115.Very well done.

Depending on how steep the cost will be, I'd be interested.

Mike

Upvote 0

Very nice man! very very nice! I am not sure if youd be interested but if I love this wildcat BT I just got, would you be interested in making a few of those mags if I sent you one??

Upvote 0

Eh, I could give it a try but it’s quite a long shot: getting this impact mag to where it is now took about 6 months of iteration and hundreds in tools, materials and custom fixturing. So making a reliable mag for a gun I don’t have to test with will be difficult.

Very nice man! very very nice! I am not sure if youd be interested but if I love this wildcat BT I just got, would you be interested in making a few of those mags if I sent you one??

Upvote 0

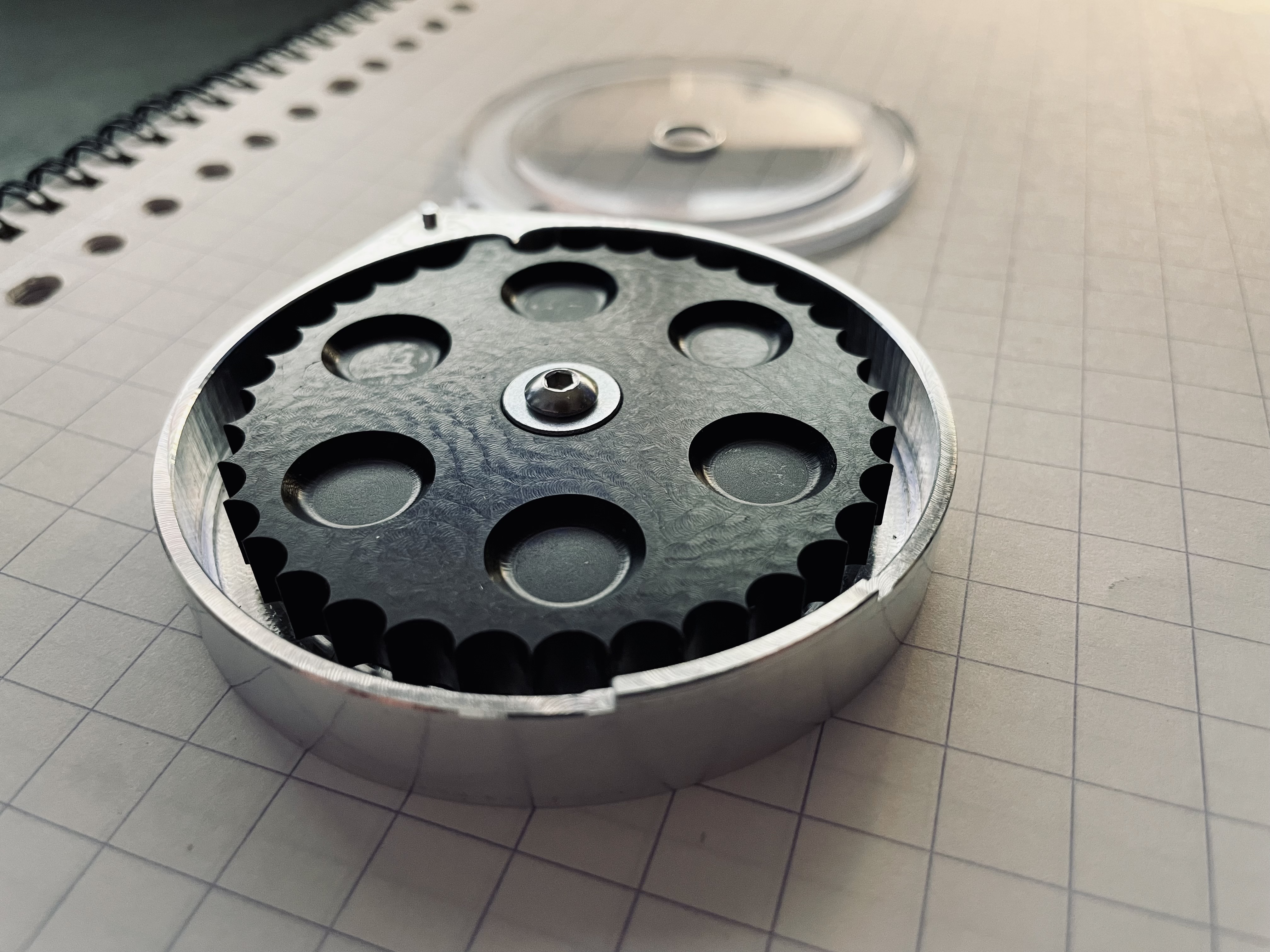

Final version is done, production can start. They'll be anodized, but I think the raw aluminium looks pretty slick too! I've included a picture of all the different pellets/slugs I've tested so far, all without a single jam. The polycarbonate mag cover is less scratch-resistant than I would have liked but that's well compensated for by just how sturdy this stuff is: I physically could not snap it in half. I really tried. The groove above the pellets/slugs is opaque, which is unavoidable when machining clear plastics, but as you can see from the pictures it's still quite easy to see how many rounds you have left. If you're interested, I'll make them on request. €114 including VAT (hey, I said I'd try to keep 'em below €115  ).

).

A big thank you to you guys: the initial interest I got on this forum on my post about a replacement aluminium factory housing inspired me to start this project and kept me motivated through a mountain of "almost there but not quite" attempts.

A big thank you to you guys: the initial interest I got on this forum on my post about a replacement aluminium factory housing inspired me to start this project and kept me motivated through a mountain of "almost there but not quite" attempts.

Upvote 0

Upvote 0

They look great! The raw aluminum with the tool marks is not an issue for me as I think it adds to the cool factor.

Upvote 0

In my opinion it looks the best too. I'm starting my first medium-sized production run in the next few days and those will go to anodizing (make the whole thing look a bit more "professional" and minimize friction) but hopefully the anodization layer will be thin enough that the toolpaths will still be visible!They look great! The raw aluminum with the tool marks is not an issue for me as I think it adds to the cool factor.

Upvote 0