I recently installed a Huma regulator in my FX Wildcat MKII. The bad news is it didn't go smoothly as seen in Airbuks' YouTube video. The good news is there was no irritating background music during my install as there is on that same video (also I finally was successful after several days of research, testing, and scouring airgun blogs.)

While the video is pretty much correct and helpful, it did nothing to guide me through the numerous complications, unexpected problems and detours I encountered along the way.

Over the next few days I will add posts each detailing a lesson learned (I have about 10 of them.) It is my objective to share my experiences in the hope it will assist other Wildcat owners doing this worthwhile upgrade.

*** I am not an expert on any of this stuff and may make incorrect conclusions or make incorrect statements. If you see any of these please respond. I am not the sensitive type and would appreciate your insights so I can learn even more. ***

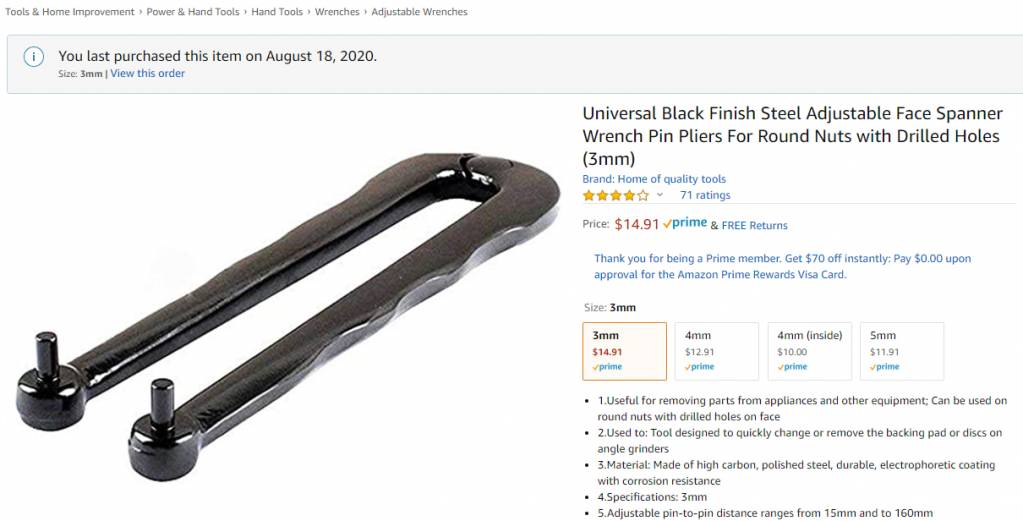

Lesson #1 - BUY A SPANNER WRENCH for $15

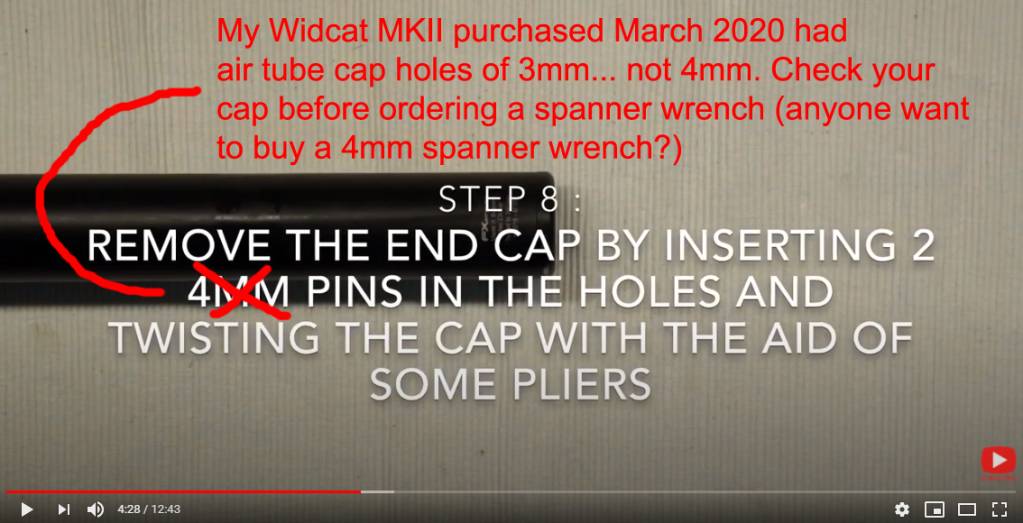

To remove the old regulator and install the new one, you will have to remove the air tube from the frame and then unscrew the air tube's end cap. The on-line instructions I found all showed this being done by inserting a pin of appropriate size into each of the two holes in the air tube's end cap. The instructions then show a pair of pliers being used to simultaneously grip both pins and rotate.

The problem I encountered doing this was that one of the pins "leaned" during the attempt (yes… pins were correct size and fitted deep and tight.) I found that because the two pins were not connected to each other they could move independently. Considering the inexact, crude grip regular pliers will have on the pins, more force may unintentionally be applied to one pin than the other pin. My end cap was quite tight and after carefully trying to rotate the cap with pliers, one of the pins leaned over.

I ordered a 3mm spanner wrench (prior I ordered a 4mm spanner wrench as shown on the video which did not fit my 3mm holes) on Amazon for $15. It arrived in two days and worked extremely well. Money well spent!

Because the two pins on the spanner wrench are physically connected to each other, one pin cannot go off and "do its' own thing." The two pins must work together, like two oxen in a yoke. This insures two things: 1) both pins always exert equal pressure on both holes and work as a team, and the pins can never "lean over" because they are welded to the wrench handle.

While the video is pretty much correct and helpful, it did nothing to guide me through the numerous complications, unexpected problems and detours I encountered along the way.

Over the next few days I will add posts each detailing a lesson learned (I have about 10 of them.) It is my objective to share my experiences in the hope it will assist other Wildcat owners doing this worthwhile upgrade.

*** I am not an expert on any of this stuff and may make incorrect conclusions or make incorrect statements. If you see any of these please respond. I am not the sensitive type and would appreciate your insights so I can learn even more. ***

Lesson #1 - BUY A SPANNER WRENCH for $15

To remove the old regulator and install the new one, you will have to remove the air tube from the frame and then unscrew the air tube's end cap. The on-line instructions I found all showed this being done by inserting a pin of appropriate size into each of the two holes in the air tube's end cap. The instructions then show a pair of pliers being used to simultaneously grip both pins and rotate.

The problem I encountered doing this was that one of the pins "leaned" during the attempt (yes… pins were correct size and fitted deep and tight.) I found that because the two pins were not connected to each other they could move independently. Considering the inexact, crude grip regular pliers will have on the pins, more force may unintentionally be applied to one pin than the other pin. My end cap was quite tight and after carefully trying to rotate the cap with pliers, one of the pins leaned over.

I ordered a 3mm spanner wrench (prior I ordered a 4mm spanner wrench as shown on the video which did not fit my 3mm holes) on Amazon for $15. It arrived in two days and worked extremely well. Money well spent!

Because the two pins on the spanner wrench are physically connected to each other, one pin cannot go off and "do its' own thing." The two pins must work together, like two oxen in a yoke. This insures two things: 1) both pins always exert equal pressure on both holes and work as a team, and the pins can never "lean over" because they are welded to the wrench handle.