You analyze not the real cut, but the screenshot of the part, made not perpendicular. Look, I just open it in the editor and make the horizontal line, you see it doesn't match the corners. Now have a look at the "steps" and just imagine (in case the shape is really like that) what tool and by what process it could be made, taking into consideration that it is the revolving detail.

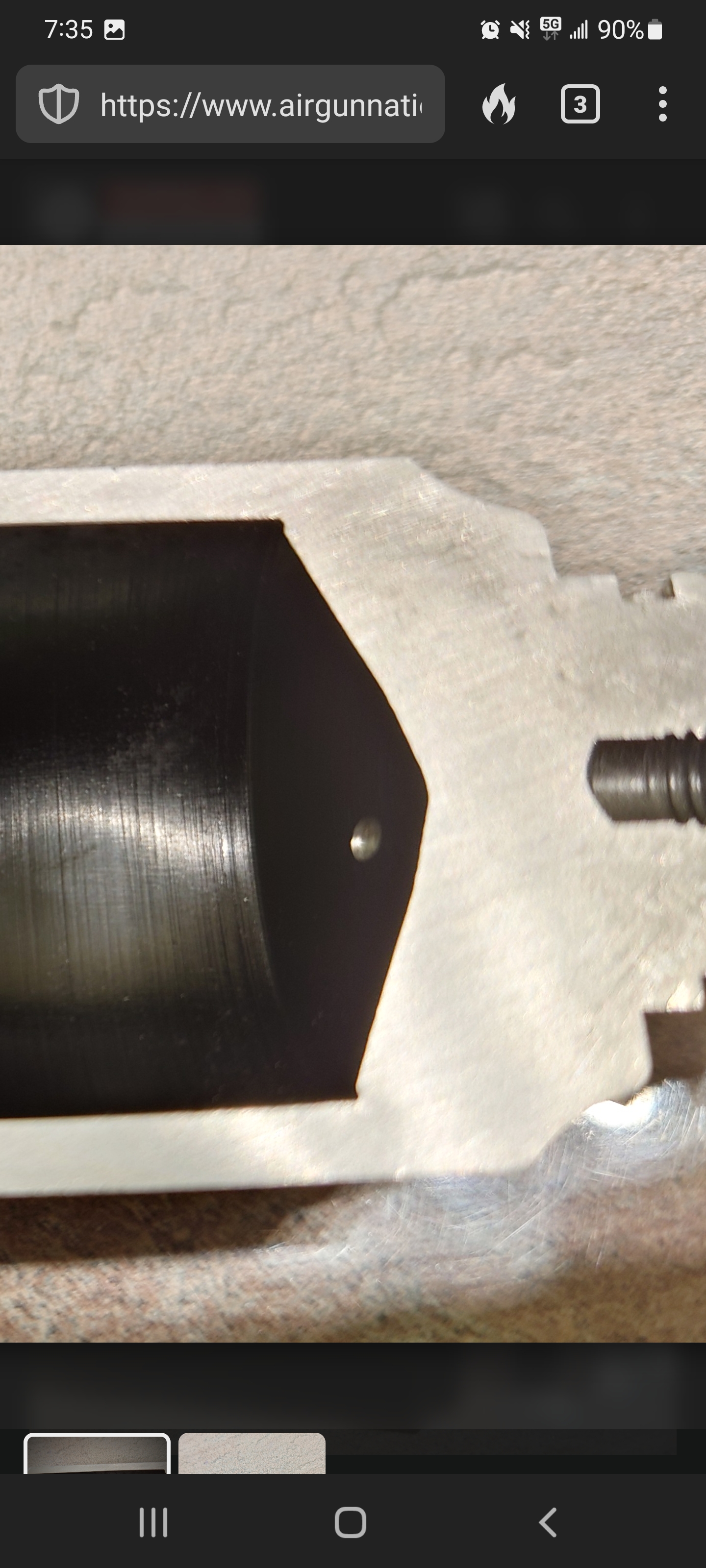

That is just artefact of the image. You can ask Marko to make a normal picture of it. Plus to it, there are, looks like, burrs on the part, he didn't remove them by polishing as I did and as you can see at the bottom screenshot.

View attachment 353378 For flat bottom we use that kind of drill.

View attachment 353398 Have I ignored it? Well, I am sorry if I gave you a chance to think that I ignore the "unakward" questoins. I just, really, didn't see it. Anyhow, as I've just said -- imagine if it is a real geometry, how revolving part could be made with such steps, moved in one side, though they should be simmetry from the center of the revolving. Do you get what I mean?

You are absolutely right and that is what I've tried to bring to

The different high pressure revervoirs have different requirements for calculation and design and different requirement for safety, including the coeficient. And for the reservoirs with the volume less than 1 liter they are different rather than to huge tubes. The same with the standard 6.8 liter tanks, the working pressure 300 bar, test pressure 450 bar, the same as for any air reservoirs for PCP guns. And asking why not 3.5 coeficient that is just... Well, you got it. As we joke here, all those profeccional virusologyst now turned to be the war profeccioanls...

Nobody knows, the expertise is ordered (by they way it cost me 200'000 roubles, about 2'500 USD) and it will be made by the special criminal experts in Moscow, State experts, not the private ones. I do hope they will answer all the questions.

You are asking about the 3D models and don't say what programm are you going to use and what math model for simulatoin? Are proffecional in what you are asking?

OK, guys, I am about to leave for goose hunting, then to abroad trip and in the best case will come back towards the end of May. So, having not hearing me here for next couple weeks or more don't think I am hiding

Nobody can force me to avoid fight, I just love it! When I get the experts' conclusions I will share it with you.