My wife tells me that my ability to speak long speeches or write long texts, with detailed explanations just suffocatingly killing. I believe her, she is very the closest person to me. She suffers of it every day!

Anyhow, sometimes it is necessary to go that way. Not for convincing somebody in something. Not at all, mostly for having the confidence, that "I've done my best, trying to provide the full information and if even in this case the opponent fails to understand, since now it is not my problem!"

I am apologizing to those small number of people who either supported me or stayed cool-headed for me being out of this discussion for a while, I had what to say from the very beginning, but in this case if would look like barking dogs divided by the fence. So, I had to wait. Thus, any assumption, that this funny guy Lukaz with such childly way to hit me would run me to the offended status and turn me out of communication with my customers is ridiculous. For 20 years I am so used to that that it started to be so boring, to see the same primitive scheme of behavior. I eat at breakfast guys like Lukaz with such a predictable, flat and boring way of behavior.

It was so funny to watch how the situation evolved, the classical (and therefore so boring ...). Marko appears (by the way, guess whose gun he's dissected?) with "fantastic" and shocking information to get the attention of the audience. The situation is rolling up, more and more people are involved in it. As always happens in such hype situations, the mob starts to throw a fit (you have to remember that the IQ of the mob is equal to IQ of the dumbest member of the mob, this is a scientific fact, that is why you should avoid any mob if you want to keep your mind clear). And here he is, a hero with an IQ of humanity's top 1 % (after such a statement time to start laughing, so arrogant and self-confidents person quite difficult to find, remember Socrata used to say "I know exactly that I don't know anything!", but that is not about Lukaz) -- welcome, Lucaz, the conductor of the hype! He either denounces or calms down, trying to look like the objective, side, observer.

Anyhow, let's go back to topic. The fact is, it begins when Dave has an accident with the reservoir of L2. That is the only fact we know for sure. Nobody knows what was the reason of that, either the wrong design, the wrong material, the misuse by Dave or combination of all those factors. But, the mob is, always, goes by the easiest way -- the taxes are up, blame bloody Russians, plain and easy to understand for the mob!

I really appreciate Dave that he has given me a chance to get those parts and find out what REALLY had happed. Yes, that takes time, you all know the situation, even before the war the post communications between the countries wasn't very fast, now it is terrible but I got the parts anyhow.

I got it towards the end of April. The fact is Russia has long holidays in May, from 1st of May up to 9th of May, the celebration of our Victory over fascism (looks like we are back on the same way, need to defeat new fascism again). Nobody works those days, like during the long New Year holidays. In fact I hate that I consider these too long and in this situation we have to work as hard as possible. But, anyhow that is the reality. After the hollydays we will send the remains to the special laboratory. The test there will take another month or so. That is the objective factors but not my attempt to hide the situation. I prefer act step by step rather than run in any way that looks easy to go. The facts, analize, conclusions. That is the only way, unfurtunately people forget that that being fooled by the Media, facts matter, but emotions.

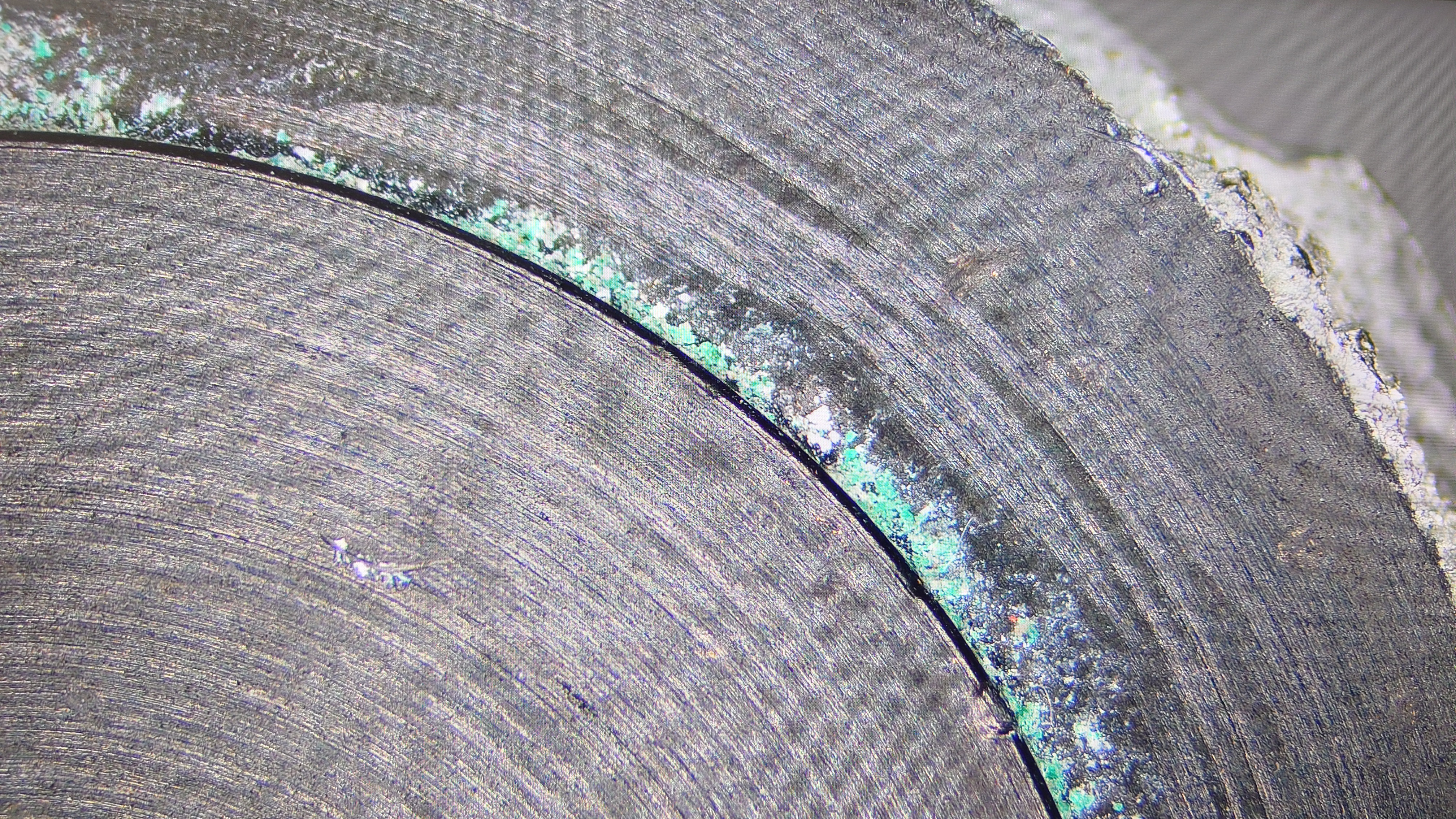

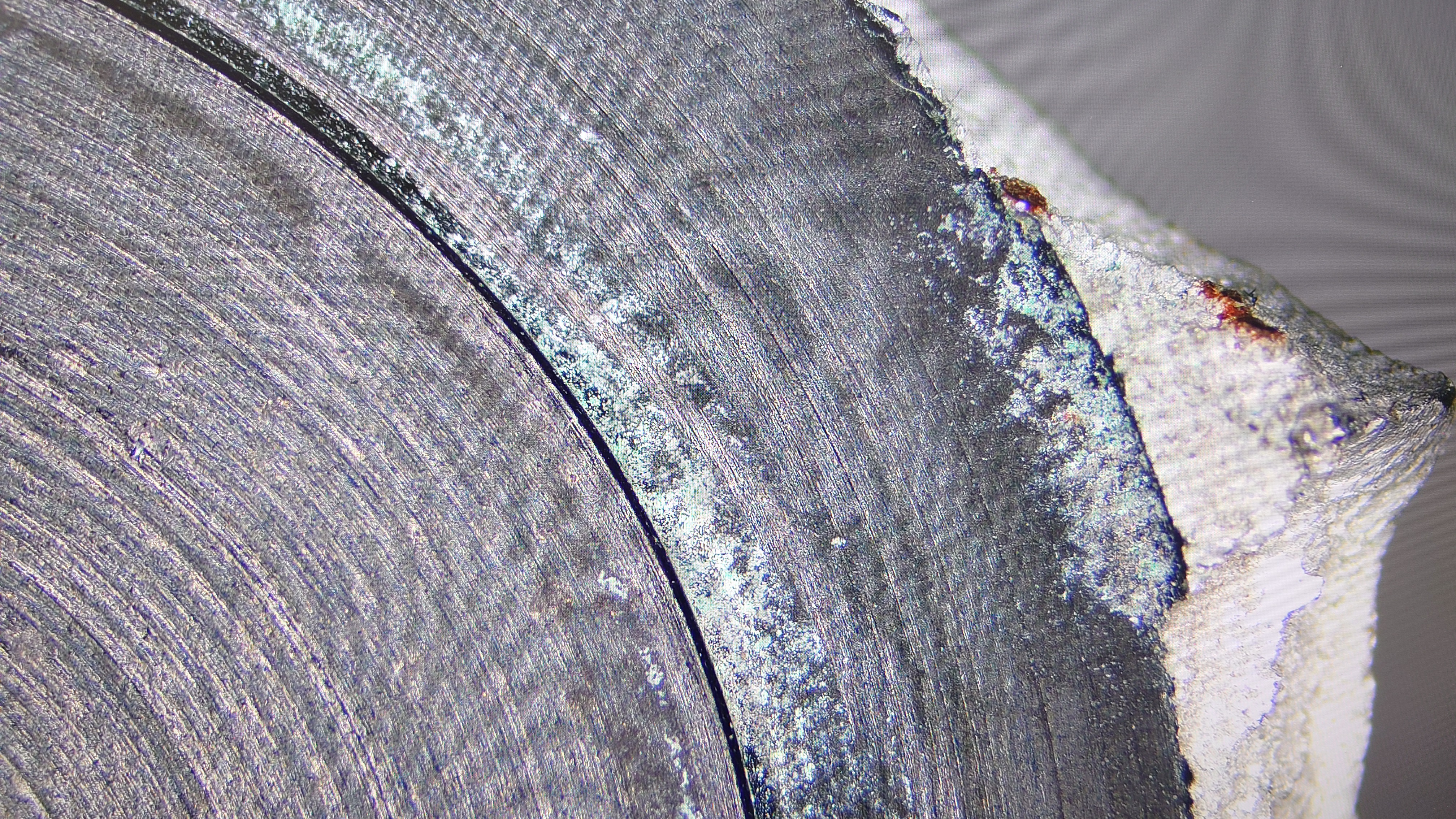

Meanwhile I have examined the remains with the microscope and found some interesting details. The surface of the material is like burned or corrosive. The most interesting thing is that it exploded like it had something inside, and the destroying of the reservoir starts with the thread part, not the bottom (we will talks about "weakness" of the bottom part below). That is quite strange, since, based on my experience and the normal physic the exposure is the process of the widening of gas. When the volume of the gas has huge excess of volume where it is widening. For example, the 22LR cartridge -- the maximum pressure it can give about 130 MPa. Looks serious. But only in case when the gas extends in the close volume, make a hole in the barrels or just drop the cartridge in the fire -- you even will not notice that energy.

When the reservoir destroys due to the material failure, the character of the damage looks different. But when it explodes with the oxygen -- looks like that! I don't want to say anything now, before the expertise, I just tell you what has caught my attention. And my, preliminary conclusion can be wrong, there is still the possibility of the wrong material, no doubt. Let's wait for the conclusions of the experts.

On the other hand, if we try to observe the situation like cool-headed men, not like hysterical women in PMS days -- EDgun has sold over 17'000 L2 towards now. With all the previous made models for 20 years I estimate the whole number of the guns produced and sold close to 100'000. From the very beginning we use ONLY Russian D16T for all high-pressure parts. The guns were neglected drop from the height, suffered the fire, were run over by tracks and so on, never ever we got any problem with that. When some of you want to fall down to hysteria, and is ready already to cut the reservoir a half to check it out -- just think about it. You are manipulated. That is only your choice what way to go, to remain a normal men or became a puppet. Consider the facts, not emotions. The fact is -- over 20 years, over 100'00 guns no one found damage of the guns due to the design and, of course no one hurt or death due to design.That is the fact.

Anyhow, let's go back to topic. The safety of the high-pressure parts. Unfortunately, we all are used to that and don't consider that is high pressure is can really be dangerous. Being in that business over 20 years I know that for sure and thus we still, as at the first time, when we were very afraid of such a high pressure, follow the definite routine working with the high pressure parts from the very beginning, from the choosing the material. Somebody says about Titanium parts. The point is not in the cost of that (besides Russia is the biggest manufacturer of titanium and if we stop selling it I am wondering if you will still fly with Boings or Airbases

), the point is in the excess of necessary safety. I am an engineer, all my team are engineers, we've been taught to design ANY object based on principle of reasonable sufficiency. The request "let's make the high pressure tube of steel" shows just lack of knowledge of the topic, it is like superstition instead of the scientific approach. The modern aluminum alloys gives the necessary strength, resistance to the cycling load and long life of the reservoirs. That is obvious and I have no intention just to try to talk anybody into it.

OK, now it is time to talks about information presented by Marko. What is Marko wrong about? He applied linear static analysis to the case of plastic deformation. It is not correct. Either he is not a professional, or he deliberately misleads people. (I am very trustful person and believe that Marko was used by Lukaz just as the tool for his own personal vendetta

) Any sane person would have a question, how, with such an extreme stress (according to Marko's model), the bottom is not damaged at working pressure and is not damaged when the operating pressure is significantly exceeded while hydrotesting?

In reality, in the “weak” point (fillet), the internal stress will never achieve such extreme values, there will be a plastic deformation of the material in this point and a redistribution of the load on the less loaded metal around this point.

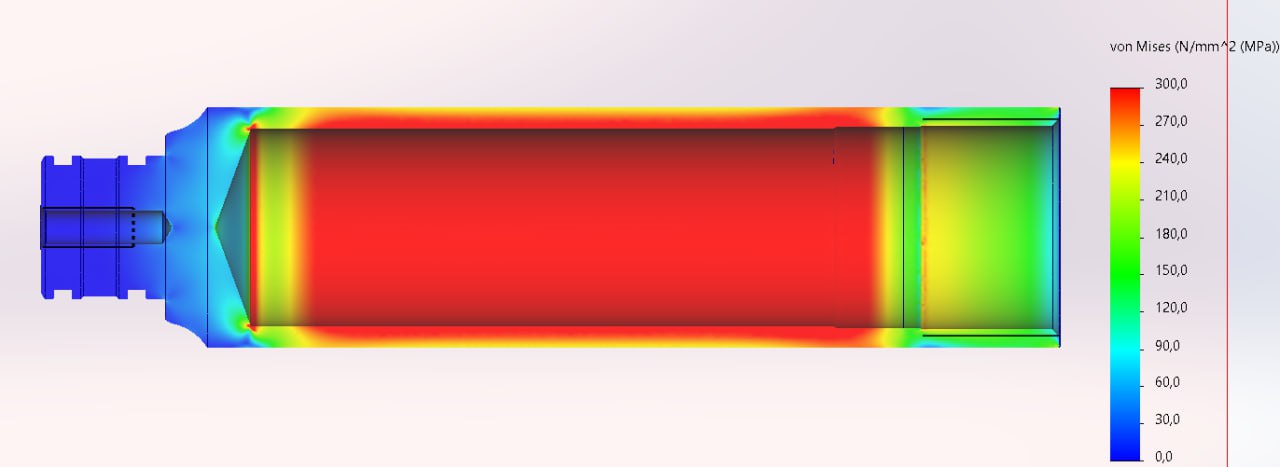

For a correct assessment of the strength in case of plastic deformation, a nonlinear static analysis is to be used, which takes into account the plastic properties of the material. The results (shown below) show that the reservoir is designed correctly, and the weakest point of the tank is a thin strip in the O-ring area.

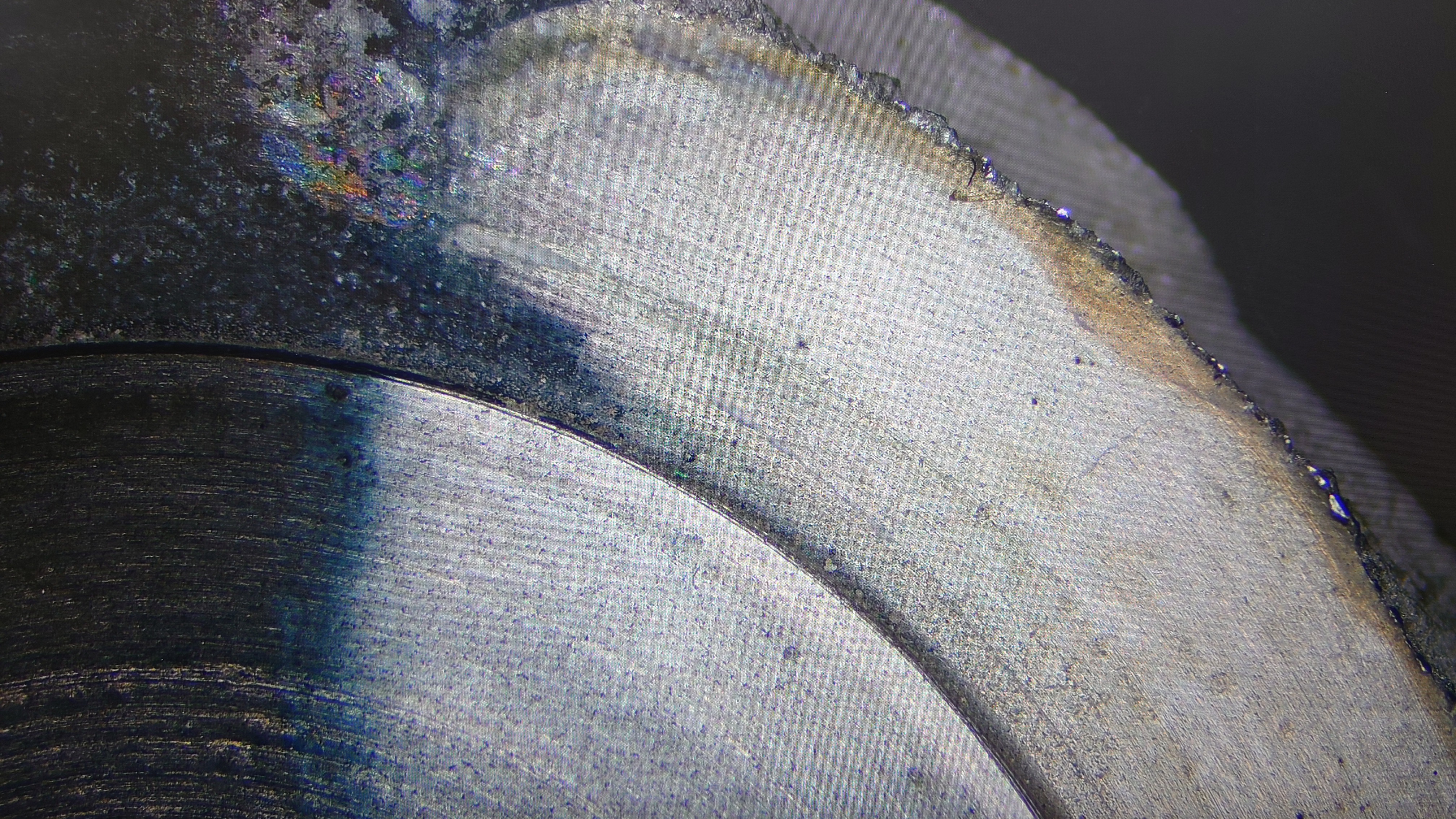

And this is not accidental, it was designed to eliminate problems associated with possible uneven strength along the axis of the reservoir. If, for some reason, the reservoir goes beyond the point of plastic deformation (for example, as a result of heating during a house fire), then the place around the O-ring is deformed most of all, and air leaks out in this point. By the way Anna, my daughter, used to make the temperature test and you can see what happened to the reservoir while being heated:

And that is exactly what found Marko while making his test. That's the way it should be. That point is designed especially that way to have it as the safety valve, in case of the starting the damagine of the material, the O-rings here will lose the germetization and the pressure will drop down, without the explosion. According to the overall strength of the reservoir, there is the National Standard of the Russian Federation number GOST R 52857.1-2007 with the name “Vessels and apparatus. Norm and methods of strength calculation. general requirements". This standard was used in the design of the reservoirs and the reservoir fully complies with the requirements of this standard. Perhaps this standard has some differences in nuances with the national standards of other countries, but believe me, in any country people want to stay alive the same way (although the media may lie to you), and the same laws of physics apply while creating the standards.

At the picture above there is a result of a non-linear static stress analysis in a reservoir loaded with a pressure of 650 bar. At this pressure, plastic deformation occurs in the entire thickness of the reservoir in the point of the O-ring

The allocated volume of the reservoir metal is plastically deformed at a pressure of 650 bar. the arrow shows the place where the plastic deformation covers the entire wall of the reservoir. And that meets the result of the hydraulic test, made both by Marko and me (the result of that test will be bellow). The plastic deformation starts over 650 bar, as it was designed. Well, I know somebody would want to have it workable up to 1 000 bar, but remember about principle of reasonable sufficiency. We don't have access to the compressed air over 300 bar and 500 bar is more than enough for anything that could happen to the reservoir in the real life.

I know they will yell "That is the cone shape bottom, but we were tested the flat bottom"! OK, guys, no problem here is the flat bottom.

So, as you can see the picture of the strength is the same and meet the safety requirements.

Anyhow, according to the Marko's "model" the reservoir should be destroy, but in fact he failed to destroy it, as well as I have failed to destroy it with about 800 pressure. Watch the facts, not speculations. I will, no doubt, try to destroy it, when I get a new pump up to 1'200 bar, but I doubt that I will be able to do it, most likely the O-rings will be destroyed first, not the metal. As soon as I have that test made I will, defenetly, share the results with you.

Meanwhile there are the results of the test I made recently. And the result of this test exactly meets our calculation and modeling, that prooves that we are on the right possition, in comparison to Marko.

At the end, me, as the manufacturer is the most concerned person regarding the safety, you should understand it if you consider the facts not the emotions. I've built that business during over 20 years not for to destroy it in one second by my own neglectness. No doubt, we, as any of the manufacturer can meet the wrong material (remember Challenger exploded because of the fail sealings). We can meet failure of the employee (remember how many people were killed in the air crash of last two 737 Boeings due to the mistakes in software), but we never ever will be neglect to the whole process of designing of the gun, choosing the materials and producing the guns. I earn enough money not to save it on the safety issues and every case, like David's will be precisely investigated by us, in order to find any possible mistakes from our side and remove it immediately.

Keep watching the update of the information from us.

I hug you all as my brothers in arms, no matter what contry we live and what langauge we speak!

Yours trully

Ed