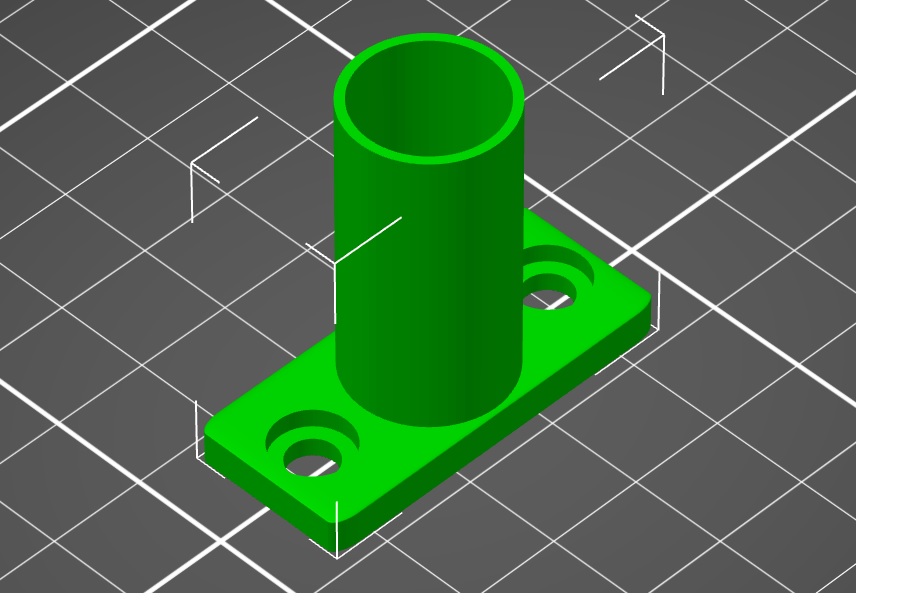

Another way to improve L2 when replacing barrel, to lock this tool before removing barrel. Worked for me:

View attachment L2-BARREL-INSTALL-TOOL.1650724932.stl

View attachment L2-BARREL-INSTALL-TOOL.1650724932.stl

Upvote 0

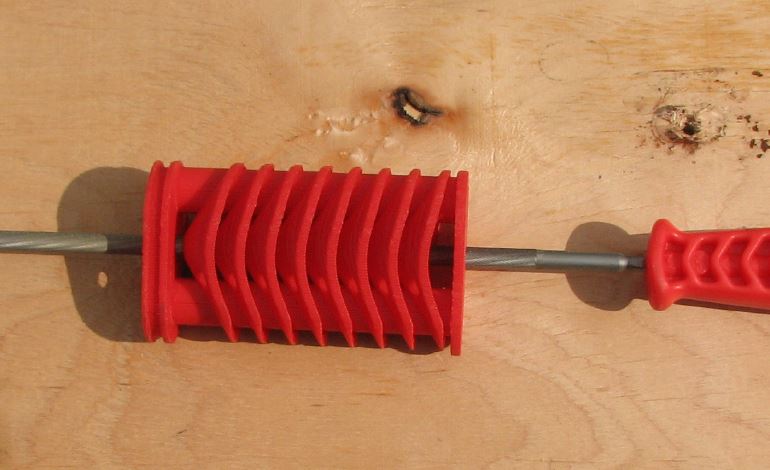

Here is a version of locking pin, hate guns in red:

I'm curious how much clearance are you giving the pellet path in the original design? PETG tends to be a bit gooey to print with and my pellet path was lightly covered over printing following your orientation.

when printed in the horizontal position and with the pellet channel unsupported you might get a small hang from the upper perimeters, I do not know how PETG react to machining but I cleaned up my print in PLA Max (5-6 times stronger than normal PLA) with a 5.5mm chainsaw file

Does anyone sell the 3d printed baffle inserts for the Leshiy 2 350mm? If so please contact me.

Does anyone sell the 3d printed baffle inserts for the Leshiy 2 350mm? If so please contact me.

If you have access to an .stl file, you can upload it to a site like shapeways. They will print and mail it to you, for a small fee. I think I've seen some baffle .stl files on thingiverse.com.

Does anyone sell the 3d printed baffle inserts for the Leshiy 2 350mm? If so please contact me.

If you have access to an .stl file, you can upload it to a site like shapeways. They will print and mail it to you, for a small fee. I think I've seen some baffle .stl files on thingiverse.com.

Huh? - LenaTo posted the files at page 3 in this thread

Anyone will to print and sell me a regulator adjuster?

shapeways.com can print and ship for $30 roughly...I dont have a printer. is there anyway i can buy those from ya? I need 3 loaders for 25 cal.

Anyone have a link to a baffle removal vid?I was planning on making a full tutorial but I really will not have enough time as I will be very busy and it is very easy anyway.

I will give information as much as possible.

Disclaimer: I hold no responsibility whatsoever if you damage your air gun while using this baffle.

every 3d printer is different so you have to make sure tolerances are good to go before shooting through it.

3d Printing Orientation (print horizontally with support on bed):

View attachment 152183

View attachment 152197

after that clean up the print then use a 4mm Allen key to round off these two holes.

View attachment 152211

install the baffle and tighten both screws (insert screws from bottom and use a screwdriver to guide them into the hole then tighten using an Allen key from the top)

also ensure the baffle is flush with the front moderator plate (the two small pins should slot into their respective holes.

don't forget to put the O ring.

View attachment 152223

assemble everything then check the barrel from the back side to ensure no obstruction (for my L2 when I look through the baffle I can barely see the edges of the baffle center hole)

View attachment 152232

keep in mind the center hole tolerance is very tight so ensure everything is ok before test firing.

if you don't want it to be very tight you can widen it by shoving a 5.5mm Allen key (for the .22 caliber) in the center of the baffle and rotate the Allen key to round off the hole and slighting increase the size. ( keep in mind that the tighter the hole tolerance the more reduction in sound )

you can do the same for other calibers with different size Allen keys.

your results may vary based on your power settings.

Enjoy.

View attachment 152236

View attachment 152237

View attachment 152242

www.shapeways.com $70 bucks shipped...Does anyone sell the 3d printed baffle inserts for the Leshiy 2 350mm? If so please contact me.

Silent Thunder Ordnance sells 3D printed inserts for the Leshiy 2. A few here have said they work really well.Does anyone sell the 3d printed baffle inserts for the Leshiy 2 350mm? If so please contact me.

Thanks for the heads up. Cool site!Silent Thunder Ordnance sells 3D printed inserts for the Leshiy 2. A few here have said they work really well.

I just checked. $88. I'd order one myself but they are out of 22 for now.

Printed this design as well. I added some high density foam to the rear section around the barrel and in the baffle fins similar to Silent Thunder Ordinance's design. It works really well over stock! No meters or anything I just recorded the sound from the same spot and the difference is very noticeable. Stock Baffle Video- 1st and 2nd are into the dirt and the 3rd is on steel. 3D Printed 1st is on steel 2nd in the dirt. Tyyou are welcome!

if you are using .177 I have attached a .177 version which has a 5mm pellet path.

View attachment 152961

did u notice any difference between the normal and B model? I have the 350mm barrel so when I designed the B model the barrel doesn't actually go past the holes in the baffle but in your 250mm version the barrel is well past the vent holes which is not what I intended.

View attachment 152965

I think for L2 short versions it is better to stick with the normal version.