You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

N/A lapping a barrel

- Thread starter Groucho7

- Start date

Dillon, clearing the burrs with a fine abrasive like J-B bore compound, it would be tedious, yes. Still less time than packing up the barrel and making arrangements to have someone else do it. Besides, what do you have to loose for having tried other than a half hour of your time? If the result is not satisfactory, you can still send it off.

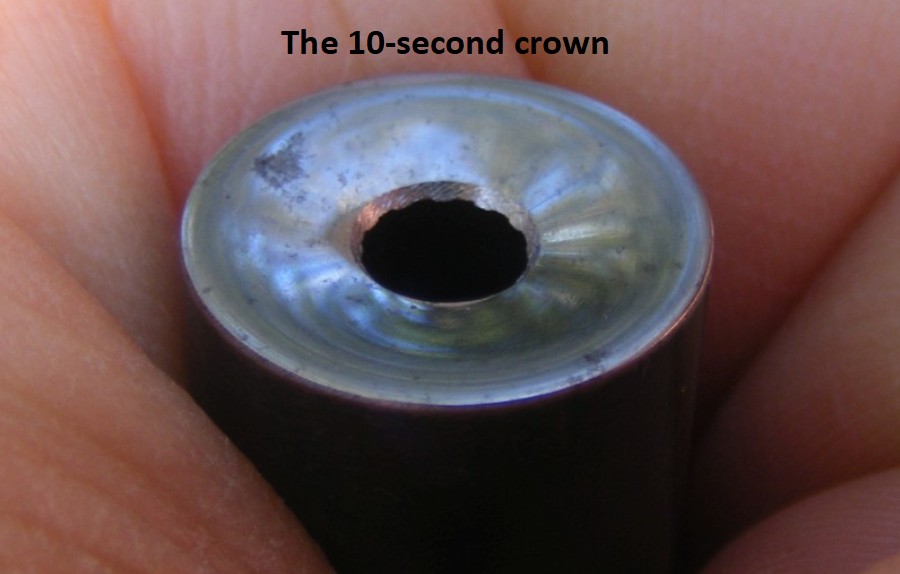

BTW, not that I recommend it but here is a silly experiment to see what a 10-second crown job can be. Inspired by the atrocious crowns many people were getting on the cheap Crosman Icon PCP, I grabbed a barrel in the shop and hit it 3 seconds with a carbide burr followed by 7 seconds with a diamond ball.

The result is vastly better than a lot of production barrels I’ve seen. Which is sad when you think about it.

BTW, not that I recommend it but here is a silly experiment to see what a 10-second crown job can be. Inspired by the atrocious crowns many people were getting on the cheap Crosman Icon PCP, I grabbed a barrel in the shop and hit it 3 seconds with a carbide burr followed by 7 seconds with a diamond ball.

The result is vastly better than a lot of production barrels I’ve seen. Which is sad when you think about it.

Upvote 0

If your going to disagree then publish the rule please.

Let me rephrase my opinion: "Good golly, not another example of embedded opinion rooted in only one understanding of a subject then held so rigidly as to not allow other examples of the same outcome to be published."

Better?

Exercise common sense and be considerate towards your fellow users. The diversity of opinion and intelligent civil discourse is encouraged; by the same token: rude, lewd, vulgar, obscene, flaming, baiting, trolling, hateful, threatening, insulting, violent, or slanderous content will not be tolerated. You may challenge others' points of view and opinions, but do so respectfully and thoughtfully

Let me rephrase my opinion: "Good golly, not another example of embedded opinion rooted in only one understanding of a subject then held so rigidly as to not allow other examples of the same outcome to be published."

Better?

Exercise common sense and be considerate towards your fellow users. The diversity of opinion and intelligent civil discourse is encouraged; by the same token: rude, lewd, vulgar, obscene, flaming, baiting, trolling, hateful, threatening, insulting, violent, or slanderous content will not be tolerated. You may challenge others' points of view and opinions, but do so respectfully and thoughtfully

Last edited:

Upvote 0

You bring up a good point. If I have JB paste I might as well try it out. I'll need to see I remember buying a brass screw years ago to try to do it on a SPA gun but don't think I ever did use it.Guess it wouldn't hurt to try.Dillon, clearing the burrs with a fine abrasive like J-B bore compound, it would be tedious, yes. Still less time than packing up the barrel and making arrangements to have someone else do it. Besides, what do you have to loose for having tried other than a half hour of your time? If the result is not satisfactory, you can still send it off.

BTW, not that I recommend it but here is a silly experiment to see what a 10-second crown job can be. Inspired by the atrocious crowns many people were getting on the cheap Crosman Icon PCP, I grabbed a barrel in the shop and hit it 3 seconds with a carbide burr followed by 7 seconds with a diamond ball.

View attachment 458093

The result is vastly better than a lot of production barrels I’ve seen. Which is sad when you think about it.

Upvote 0

Turns out my memory ain't half bad. Well at least for this specific thing lol Wasn't gonna ship until tomorrow anyways so guess I'll give a try tonight when I have time.

Upvote 0

That combo should do the trick. Just plan to refresh the abrasive often (I.e. just add more) since J-B breaks down quickly into smaller particles. If you have a stick of medium polishing compound like the kind you load on a benchtop polishing wheel, you can scrape some of it off with a knife and mix it into a slurry with the J-B and that may help speed things along.

The two things to keep in mind are

The two things to keep in mind are

- Don’t bear down...try to maintain just the lightest of contact and let the spinning motion and abrasive do the work. If you want to apply pressure early on, that’s okay but ease up as you near completion.

- Orbit the drill randomly. This approach helps ensure you get a uniform bevel. (If instead you try to hold the drill steady, the bevel will end up biased in some seemingly random direction).

Upvote 0

Brother I want to thank you! What an amazing difference. It was much easier than I thought it was going to be. I have learned an important skill and have you to thank for it!That combo should do the trick. Just plan to refresh the abrasive often (I.e. just add more) since J-B breaks down quickly into smaller particles. If you have a stick of medium polishing compound like the kind you load on a benchtop polishing wheel, you can scrape some of it off with a knife and mix it into a slurry with the J-B and that may help speed things along.

The two things to keep in mind are

Best of luck!

- Don’t bear down...try to maintain just the lightest of contact and let the spinning motion and abrasive do the work. If you want to apply pressure early on, that’s okay but ease up as you near completion.

- Orbit the drill randomly. This approach helps ensure you get a uniform bevel. (If instead you try to hold the drill steady, the bevel will end up biased in some seemingly random direction).

Yesterday's "shot groups" at 50yds

Today's after recrown. First 2 large groups were 10 shots and seemed the barrel needed to settle? Or just me. The rest all 5 shots with 3 different pellets. Slight variable winds right to left

Last edited:

Upvote 0

Very nice! You're a natural.

Pretty cool to see the before and after, both the closeup of the crown and the results on target. With any luck, your effort will inspire someone else who has been on the fence.

Pretty cool to see the before and after, both the closeup of the crown and the results on target. With any luck, your effort will inspire someone else who has been on the fence.

Upvote 0

Perhaps I missed it earlier Dillon but what rifle is that barrel from? Congrats on a great crown job and a significant improvement.

Did you try pushing a new pellet through it after the work?

Did you try pushing a new pellet through it after the work?

Upvote 0

Perhaps I missed it earlier Dillon but what rifle is that barrel from? Congrats on a great crown job and a significant improvement.

Did you try pushing a new pellet through it after the work?

22 cal. Vulcan 3 22 700 barrel

Upvote 0

Thanks! Yes I hope others will be inspired to do so also. Was always hesitant to do so but glad you nudged me to give it a try. Did take at least 15-20min on it spread over I think 10 different times of around 2min. But like said worth the time and effort and learned something new.Very nice! You're a natural.

Pretty cool to see the before and after, both the closeup of the crown and the results on target. With any luck, your effort will inspire someone else who has been on the fence.

Upvote 0

Taipan Veteran Long .22. And thanks! I did. I pushed a few as I went along doing it and got it to the point where you can't really tell a difference between pushing up to the crown and fully through. I now reach the crown and just a tiny bit more effort pops through. Before I had to really push. I'm sure my fps on my tune bumped up too. I'll need to check that.Perhaps I missed it earlier Dillon but what rifle is that barrel from? Congrats on a great crown job and a significant improvement.

Did you try pushing a new pellet through it after the work?

Upvote 0

@nervoustrig How do you pull the lead out? I’m not familiar with this process.I assume you mean the lap was not filling out well, is that correct? The barrel most definitely must be hot and I would think a simple propane torch will heat the barrel adequately, provided you keep at it long enough to heat the steel all the way through. The way I do it is set up a heat gun and let it run on high for upwards of 5 minutes. The barrel becomes far too hot to touch ~6 inches from where the heat is applied.

I melt and pour directly from a small solder pot, meaning there is no appreciable cooling occurring at the time of the pour. I assume pouring from a ladle would be about the same provided it was allowed to soak in the pot for a bit first.

Anyway this method seems adequate to pour laps 3" or 4" long even in small calibers:

View attachment 458001

Upvote 0

If you exxpress that advice in a public appearance, you should expect many requests for your autograph.One way to look at it is, lapping is always safe because you use feedback from the barrel itself to know where and how much. The essential thing is building the experience to recognize this feedback. If you are new to it, I can’t recommend strongly enough to practice on a barrel of low importance.

Upvote 0

You’re pouring the molten lead onto a jag (or similar thing) at the end of a cleaning rod. After it has cooled, you apply abrasive to the cast lap and use the cleaning rod to work it back and forth. I included a few pictures of my setup in the following thread:@nervoustrig How do you pull the lead out? I’m not familiar with this process.

Attempting to rescue a bad barrel - the SPA M25 in .35 cal

Well I finally got a chance to revisit the .35 cal SPA M25. It's been mothballed for a while....when I set it aside, it was still producing poor groups after having taken a first pass at correcting the poor factory crown and working the bore with a cast lap. That history is covered in this...

Upvote 0