is it safe to lap a 22 cal. Vulcan 3 22 700 barrel? also can you lapp a prophet 3 25cal 700 barrel?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

N/A lapping a barrel

- Thread starter Groucho7

- Start date

Pending HOW done and using WHAT compound etc .... ?

I do so on nearly ALL my personal AG barrels, customers barrels too.

I do so on nearly ALL my personal AG barrels, customers barrels too.

Upvote 0

One way to look at it is, lapping is always safe because you use feedback from the barrel itself to know where and how much. The essential thing is building the experience to recognize this feedback. If you are new to it, I can’t recommend strongly enough to practice on a barrel of low importance.

Upvote 0

I believe it depends on the exact reference. On these forums, "lapping" is often used to refer to polishing with various polishing agents. You aren't likely to damage a barrel in that process. True lapping is done with a lead lap and various levels of lapping compounds. That is a tedious process that should be done only by experienced folks.is it safe to lap a 22 cal. Vulcan 3 22 700 barrel? also can you lapp a prophet 3 25cal 700 barrel?

Upvote 0

I’ve tried to make lead laps using old brass jags and pouring molten lead in the barrel but was never very successful. Tried with a cold barrel and also in a warmed barrel using a torch but it never worked well (for me). Anyone care to share a proper how to?

Upvote 0

I believe it depends on the exact reference. On these forums, "lapping" is often used to refer to polishing with various polishing agents. You aren't likely to damage a barrel in that process. True lapping is done with a lead lap and various levels of lapping compounds. That is a tedious process that should be done only by experienced folks.

Good golly, this nonsense again...

Upvote 0

I assume you mean the lap was not filling out well, is that correct? The barrel most definitely must be hot and I would think a simple propane torch will heat the barrel adequately, provided you keep at it long enough to heat the steel all the way through. The way I do it is set up a heat gun and let it run on high for upwards of 5 minutes. The barrel becomes far too hot to touch ~6 inches from where the heat is applied.also in a warmed barrel using a torch but it never worked well (for me).

I melt and pour directly from a small solder pot, meaning there is no appreciable cooling occurring at the time of the pour. I assume pouring from a ladle would be about the same provided it was allowed to soak in the pot for a bit first.

Anyway this method seems adequate to pour laps 3" or 4" long even in small calibers:

Upvote 0

Good point. The distinction between lapping and polishing is very important where the goal is to give high quality advice.I believe it depends on the exact reference.

Upvote 0

Yes, I used a propane torch but the heat gun seams like a better tool. Do you pour the lap in the choke or barrel?

Upvote 0

Just depends on the situation. If you're working with a barrel that has already been machined with a leade and port, it's tricky to do a breech pour in such a way that it doesn't get locked in place...a short pour, so to speak. In which case you may need to do a muzzle pour.

But if you're working with a blank, it's generally useful to start with a pour in the breech. That way you can do most of the work on the pull stroke (vs. pushing where the rod will buckle). Then once you pretty well have the bore leveled and dimensioned (e.g. worked out the tight spots and/or formed a subtle taper), you can do a finishing pass with a muzzle pour. A pour that is long enough to fill well past the choke, that way the lap is well supported when you draw it back but also has a narrower portion that will reach into the choke to dress it as well.

But if you're working with a blank, it's generally useful to start with a pour in the breech. That way you can do most of the work on the pull stroke (vs. pushing where the rod will buckle). Then once you pretty well have the bore leveled and dimensioned (e.g. worked out the tight spots and/or formed a subtle taper), you can do a finishing pass with a muzzle pour. A pour that is long enough to fill well past the choke, that way the lap is well supported when you draw it back but also has a narrower portion that will reach into the choke to dress it as well.

Upvote 0

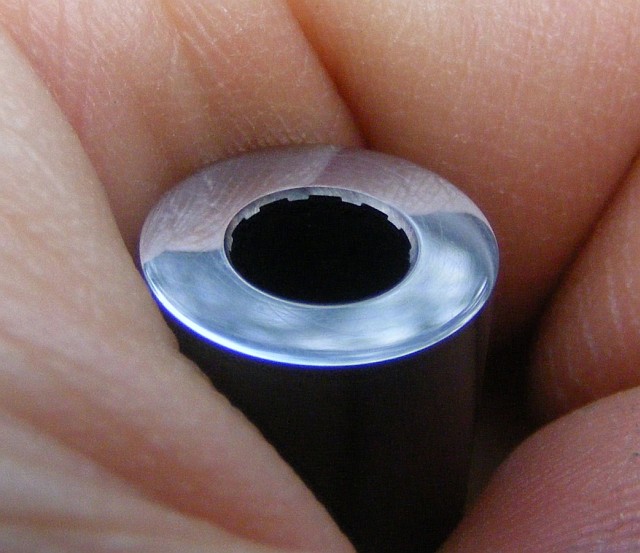

What's a good way to fix this? Pellet on left pushed through barrel, on right stopped at crown.

Upvote 0

I see some patch fibers on the crown. Does this mean the crown has burrs and is bad and needs redone? Just an amateurs guess?

Upvote 0

To clear burrs at the ends of the lands, the brass screw technique will do the trick. Light pressure...let the abrasive slowly do the work.

www.airgunnation.com

www.airgunnation.com

Barrel troubleshooting and accurizing guide

The following article is intended for the do-it-yourselfer that is interested in either finding and fixing a problem with a barrel, or improving the accuracy of an already good performer. You don't have to be a master machinist to get excellent results. The techniques described here can be...

Upvote 0

D

Deleted member 54174

Guest

That's one tight choke.What's a good way to fix this? Pellet on left pushed through barrel, on right stopped at crown.View attachment 458014View attachment 458015View attachment 458013

Upvote 0

Not a choke but I think burrs. My experience with chokes seem to be there's a good distance between muzzle and the start of choke. This literally just stops at the crown. Wasnt sure If a lap or fire lap would work or not but I guess a Crown job is in need.That's one tight choke.

Not a choke but I think burrs. My experience with chokes seem to be there's a good distance between muzzle and the start of choke. This literally just stops at the crown. Wasnt sure If a lap or fire lap would work or not but I guess a Crown job is in need.

You're going to have a pretty recessed crown to get past those burrs.

Upvote 0

D

Deleted member 54174

Guest

I see the burs, but dam if that's not choked. Wow.Not a choke but I think burrs. My experience with chokes seem to be there's a good distance between muzzle and the start of choke. This literally just stops at the crown. Wasnt sure If a lap or fire lap would work or not but I guess a Crown job is in need.

Upvote 0

And it'll take forever, but if you have the patience... Otherwise, it's a pretty quick job in a lathe if you have one, or access, or a friend, etc... But I'd definitely say it's a re-crown job.You're going to have a pretty recessed crown to get past those burrs.

GsT

Upvote 0