Would like to know if anybody has polished their laminated stocks with success. What did you use ? Or did you sand and recoat it. Currently have two cricket tact II 's. Any tips would be appreciated.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Laminated stock polishing

- Thread starter kayaker

- Start date

When you say "polish", do you mean a high gloss?

I did a crap-ton of laminated stocks in the 1990's, I sprayed them all with water based high gloss polyurethane and used 00000 steel wool to kill the shine if the customer wanted a muted sheen.

Johnson's floor wax for the final buffing, sadly, it's no longer made.

I did a crap-ton of laminated stocks in the 1990's, I sprayed them all with water based high gloss polyurethane and used 00000 steel wool to kill the shine if the customer wanted a muted sheen.

Johnson's floor wax for the final buffing, sadly, it's no longer made.

Upvote 0

I've used #7 polishing compound from ACE hardware very successfully on a Wolverine Forester and a Taipan Veteran stocks...turned out VERY nice to my eye even used it to polish the anodizing on the Veteran...looks just like black chrome...Use that same #7 to polish barrel bores also. The stuff is very benign dosn't scratch just polishes. Worked for me and I'm fussy.

Upvote 0

Yes would like a little higher glossWhen you say "polish", do you mean a high gloss?

I did a crap-ton of laminated stocks in the 1990's, I sprayed them all with water based high gloss polyurethane and used 00000 steel wool to kill the shine if the customer wanted a muted sheen.

Johnson's floor wax for the final buffing, sadly, it's no longer made.

Upvote 0

Very nice, going to look into that stuff and thanks for commentingI've used #7 polishing compound from ACE hardware very successfully on a Wolverine Forester and a Taipan Veteran stocks...turned out VERY nice to my eye even used it to polish the anodizing on the Veteran...looks just like black chrome...Use that same #7 to polish barrel bores also. The stuff is very benign dosn't scratch just polishes. Worked for me and I'm fussy.

Upvote 0

I have tried Meguiar's ultimate polish and the gold wax but it didn't make much of a difference.

Upvote 0

Looks awesome!I've used #7 polishing compound from ACE hardware very successfully on a Wolverine Forester and a Taipan Veteran stocks...turned out VERY nice to my eye even used it to polish the anodizing on the Veteran...looks just like black chrome...Use that same #7 to polish barrel bores also. The stuff is very benign dosn't scratch just polishes. Worked for me and I'm fussy.View attachment 422818View attachment 422819

Upvote 0

Years ago I became friends with a guy that did professional gun restorations on top grade Enlish shotguns like Purdy and and even Winchester model 21s. He was a big fan of Trueoil. He showed me how to prepare the wood and seal it first. The he would add about 15-20 coats(1 coat a day) of Truoil with his fingers and use #4 bronze wool in between coats. This has worked great for me over the years. If you wanted to leave it high gloss you just leave the last coat to dry (no rubbing with the bronze wool on final coat) about 3-4 days then polish it with Johnson's carnuba floor wax. I also use it coat my pellets when I want to coat them.

Upvote 0

How did you apply the polish?I've used #7 polishing compound from ACE hardware very successfully on a Wolverine Forester and a Taipan Veteran stocks...turned out VERY nice to my eye even used it to polish the anodizing on the Veteran...looks just like black chrome...Use that same #7 to polish barrel bores also. The stuff is very benign dosn't scratch just polishes. Worked for me and I'm fussy.View attachment 422818View attachment 422819

Upvote 0

I really admire your Vet. I would actually like mine to look more like this. Is it simple enough for a caveman like me to do?I've used #7 polishing compound from ACE hardware very successfully on a Wolverine Forester and a Taipan Veteran stocks...turned out VERY nice to my eye even used it to polish the anodizing on the Veteran...looks just like black chrome...Use that same #7 to polish barrel bores also. The stuff is very benign dosn't scratch just polishes. Worked for me and I'm fussy.View attachment 422818View attachment 422819

Upvote 0

The stock is easy, just use a soft rag...I use a damp bounty paper towel with polish on it..and just be careful to keep the polish out of the checkered and the makers stamp in the stock. The anodizing must be the older smooth type NOT the bead blasted mat finish. I took the tube clamps off to do the tube and the block was easy. I remember disconnecting the trigger rod...been a few years ago...member Greenarrow did his Vet with good results also...If you have the smooth anodizing I highly recommend the process.I really admire your Vet. I would actually like mine to look more like this. Is it simple enough for a caveman like me to do?

Damp bounty paper towel with the polish soaked in it....Takes a while to do the entire stock.How did you apply the polish?

Upvote 0

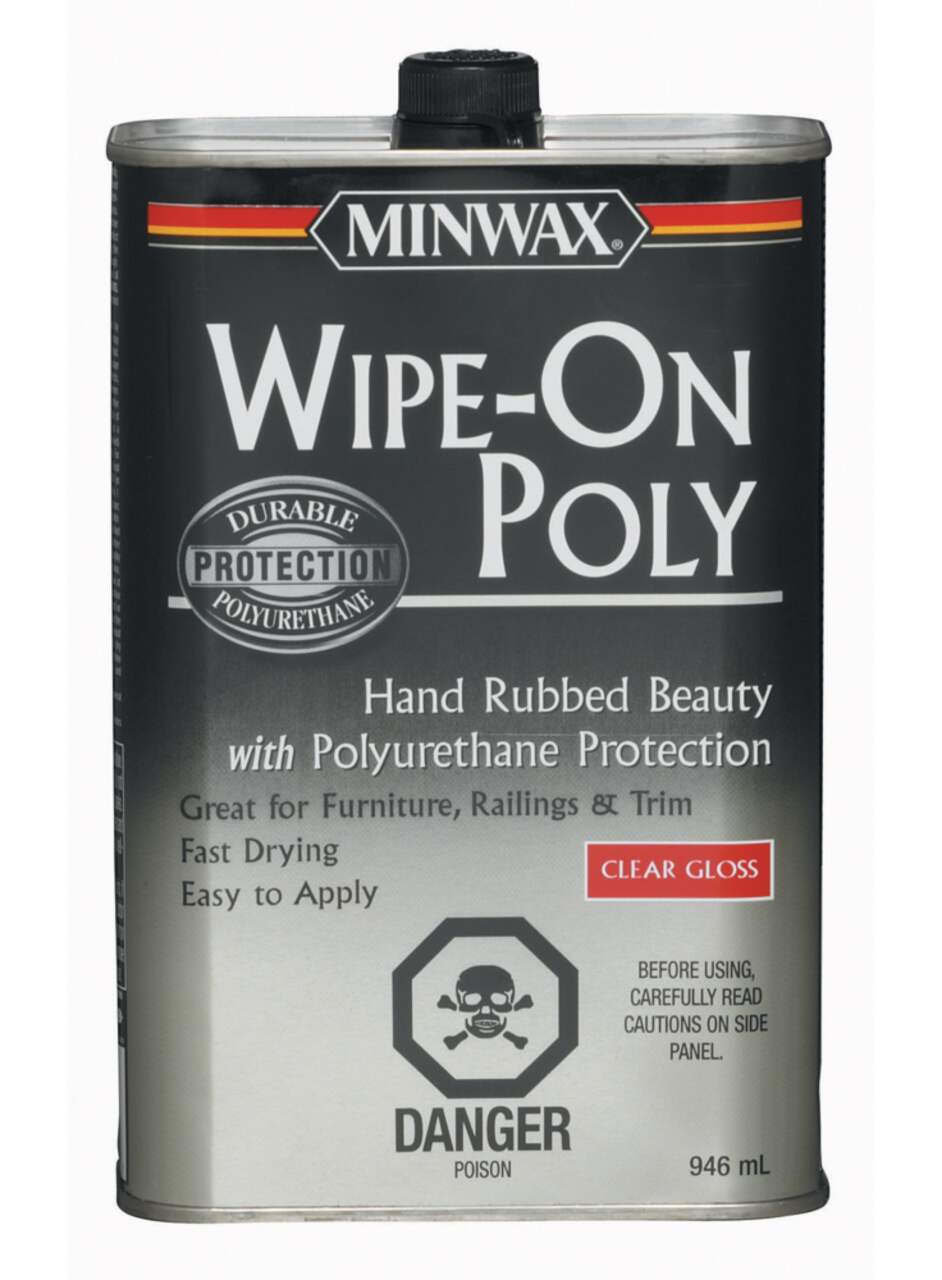

I've been using gloss MinWax Wipe on Polyurethane on my bows, slingshots and gun stocks for years.

I like it because it can be applied with a patch of cloth, pulls smooth and dries quickly to tack-free finish.

I clean the surface (and my hands) with denatured alcohol then apply just enough Polyurethane to wet the surface. It's touch-dry in a couple of hours but I wait at least 6 hours for the coat to fully harden before lightly de-glossing the surface with 0000 steel wool in preparation for the next coat. (Steel wool is oily so don't forget to clean with alcohol after use).

Two or three coats is enough for a protective gloss finish that doesn't hide the texture of the wood. Checkering or stippling should be masked to protect it. Multiple coats can be used to fill the grain if a smooth "plastic" finish is desired.

Matt and semi-gloss finishes are a gloss formulation with "pollutants" added to soften (obscure) the grain. I always use clear gloss and remove the shine by buffing it with pumice if I want a matt finish.

I've tried other products (TruOil, various other urethanes and varnishes) and find them too thick and inclined to collect dust and form drips. I dislike water based products on gun stocks.

In using any finish, your nose is the best test of "completely dry". If the finish smells, it's still giving off volatile solvents, best to wait for it to cure more.

Just my 2 cents.

Cheers!

I like it because it can be applied with a patch of cloth, pulls smooth and dries quickly to tack-free finish.

I clean the surface (and my hands) with denatured alcohol then apply just enough Polyurethane to wet the surface. It's touch-dry in a couple of hours but I wait at least 6 hours for the coat to fully harden before lightly de-glossing the surface with 0000 steel wool in preparation for the next coat. (Steel wool is oily so don't forget to clean with alcohol after use).

Two or three coats is enough for a protective gloss finish that doesn't hide the texture of the wood. Checkering or stippling should be masked to protect it. Multiple coats can be used to fill the grain if a smooth "plastic" finish is desired.

Matt and semi-gloss finishes are a gloss formulation with "pollutants" added to soften (obscure) the grain. I always use clear gloss and remove the shine by buffing it with pumice if I want a matt finish.

I've tried other products (TruOil, various other urethanes and varnishes) and find them too thick and inclined to collect dust and form drips. I dislike water based products on gun stocks.

In using any finish, your nose is the best test of "completely dry". If the finish smells, it's still giving off volatile solvents, best to wait for it to cure more.

Just my 2 cents.

Cheers!

Upvote 0

Try Mequiars PLASTX (plastic polish) for removal of fine scratches on high gloss surfaces. Been using it for years on my pepper laminate stock on my FX Boss & recommended it here before. VERY VERY fine abrasive that leaves no swirls, only shine.I have tried Meguiar's ultimate polish and the gold wax but it didn't make much of a difference.

Upvote 0