Other HPA sources I've used were a Shoebox F10 (x4 or 5 years) and a Yong Heng (x7 months). Sold the F10 as a parts donor when I got frustrated trying to source replacement parts and the Yong Heng is still ticking just fine, with the caveat that the oil gets REALLY dark REALLY quick (impending doom?). So coming from that background......

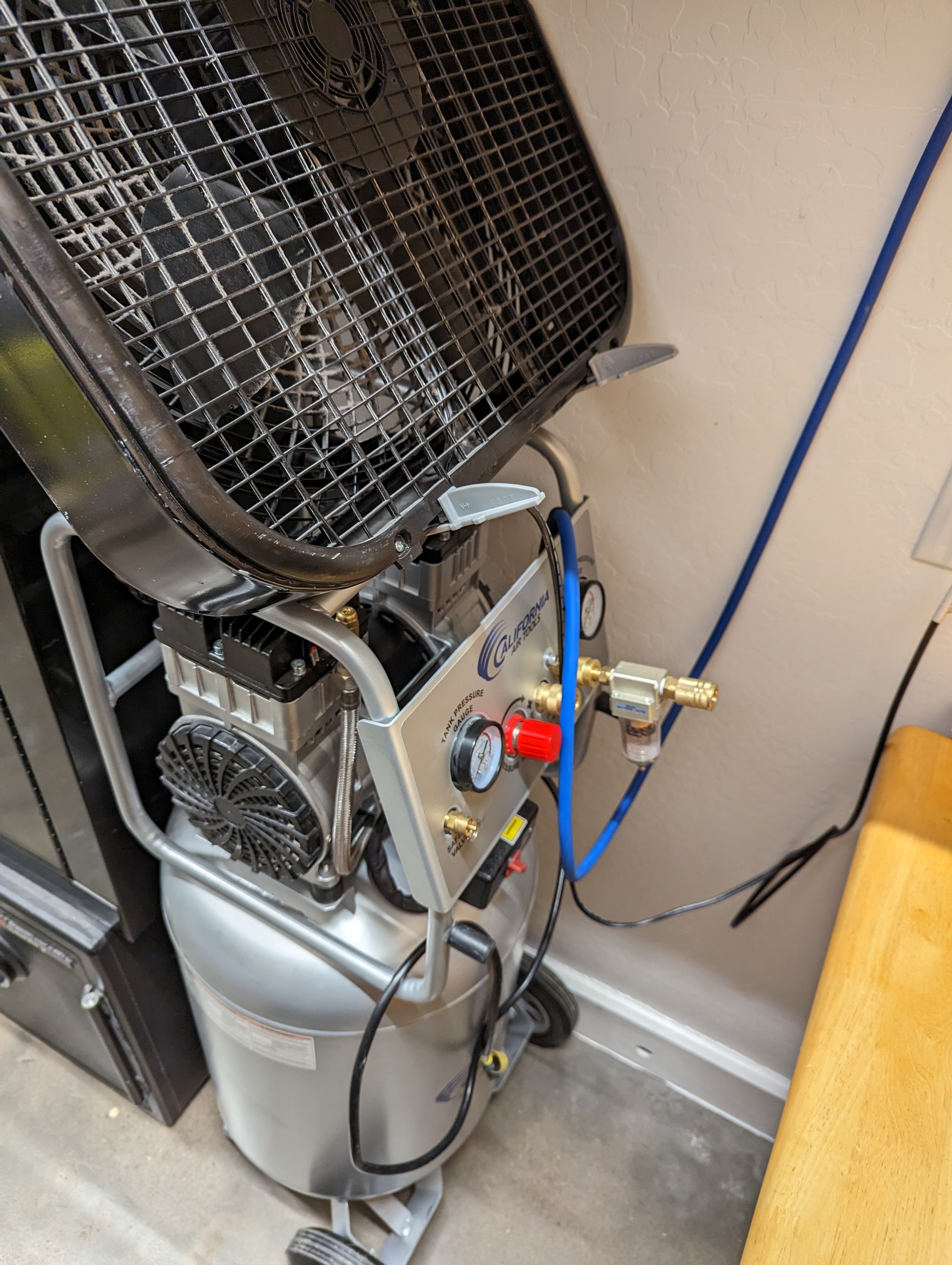

I've been debating the acquisition of a bit more reliable compressor for a couple months. Slowly narrowed down the potentials until I arrived at the Altaros booster pump. And was only pushed that direction because a really good deal on a 20gallon California Air Tools (CAT) compressor popped up on local classifieds. The lady had bought it new and used it for one job, to run a paint sprayer to redo her kitchen cabinets. So, it appears to be very lightly used.

I ordered the Altaros last Monday night and it was delivered this Tuesday, so 8 days total, I ordered the non hybrid, non bottle-to-bottle version. Sheet metal box, it doesn't look like they offer the option of the plastic toolbox like they did in the past. It arrived very well packaged, having some memory foam inside the ends of the packaging. I was previously unaware but they supplied at least a partial rebuild kit with just the purchase of the compressor. I also ordered two complete reseal kits and they were present as well. A nice little bound manual was also included.

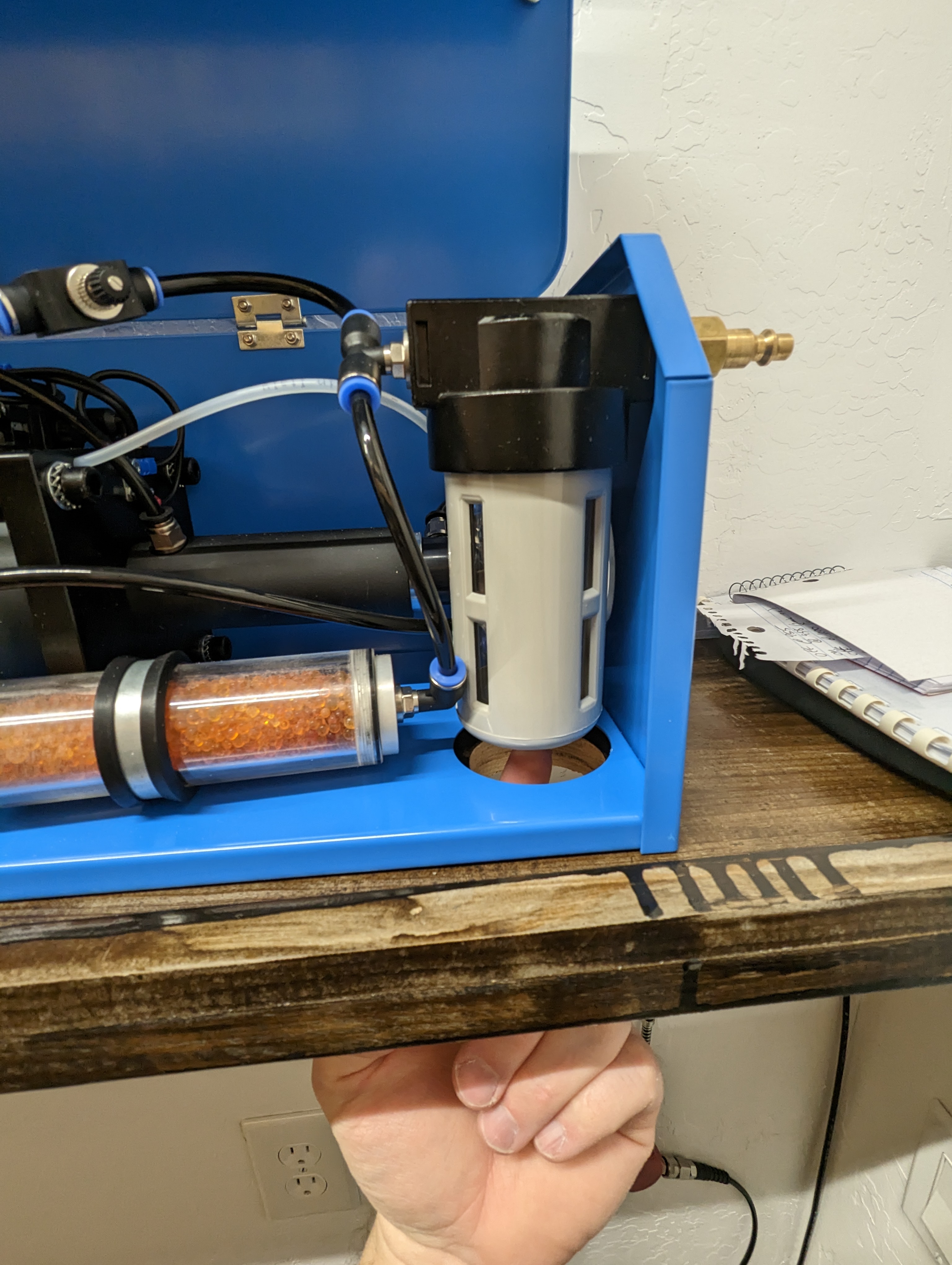

The only assembly required was to thread the male fitting for the air supply into the side of the box.

Since I wanted the booster to have a permanent home I needed to rearrange my gun room a bit. That entailed extending a shelf and moving my bottles. I like the idea of having the bottles higher than the booster but the logistics of putting heavy bottles up a wall haven't yet been addressed, so bottle are on the ground for now. I drilled a hole through the shelf right under the bleed valve to make life a bit easier. (the shelf was made from wood I scavenged during the house remodel, just wanted to point out that I'm not responsible for the atrocious stain job)

The low pressure side of my set up has 3 bleed valves: bottom of the first stage compressor, output of the first stage compressor, and the one that came with the Altaros, right where the shop air enters the booster. 25 feet of low pressure line that goes up and around other junk in the gun room, basically from one corner to the other of the room. Altaros is about 5 feet off the ground, compressor is at ground level. On the first run last night (83 minutes) I got moisture from all three bleed valves, in descending qtys (largest amount came out from the blow out at the bottom of the first stage compressor tank). The first inch or so of the silica beads within the booster changed color slightly (orange = no moisture and dark green equals saturated, per manual). No moisture was found in the fittings on the high pressure side after all was said and done. Per NWS, the relative humidity during the fill averaged 40%, but that is of course outside. The booster lives inside a well-insulated room within my garage, so likely much lower humidity.

In that 83minutes, my big 60min Drager tank went from 3900-4500psi. That works out to an increase of about 72psi/10 minutes. For reference, the F10 would increase the pressure in this same tank by 100psi every 10minutes and the Yong Heng does the same 3900-4500 run in about 15 minutes (400psi/10minutes). So, Altaros is slowest of the three options I've used.

For about the first half of that 83 minutes I was playing with the CAT's regulator pressure and the Altaros flow adjustment to arrive at the desired run/rest ratio. It started out with a 2 min run time and a 4 minute rest (40/80). Bumped the CAT's output pressure from 90psi to 110 at that point and then fiddled with the flow restrictor to eventually get 4 min run, 4 minute rest for a very conservative 50/50. It appeared to fill faster after adjustment and I think I'll have something like 80-90psi/ten minutes now that I'm at the 50/50 run/rest times. Altaros recommends 60/40 but even at 50/50 I felt like the heads on the compressor were getting a bit warm. I'll take longer fill times if it increases the longevity of the CAT. I think 90-100psi/10 minutes would be pretty feasible if I was to push the first stage to 60/40 or even 70/30, which CAT lists as the duty cycle for this specific compressor.

I babysat the system the whole time last night, but now that I've got things set up I would feel comfortable not being right there with it. I loved that about the F10 and feel it is one of the biggest pros for the booster concept. Turn it on and go about my life, no need to hang out with eye protection and ear muffs, hoping you get out of the experience unmaimed (yes, that's how I feel about the Yong Heng). The Yonger hasn't given me any reason to fear it, but that 15minutes of fill time with the Yonger is high stress; loud, obnoxious, trying to contain it (mine's a migrater), monitoring temps (water and head temp on digital read out) requiring bleeds every couple minutes and constant monitoring to prevent overfills.

As for the first stage compressor....the F10 was happy with a 6gallon 2.6cfm @90psi pancake compressor, resting 6-8 minutes for every 2 or 3 minutes that it ran. BUT I wouldn't dare try that small of a compressor with the Altaros. This 20 gallon CAT is rated for 5.3cfm @ 90psi and I don't think I'd recommend going with anything less. Just like many before me have said, the bigger the shop compressor the better, when it comes to the Altaros.

I took a page out of @Roachcreek s book and directed a box fan at the CAT's heads because I wasn't comfortable with their heat. I don't think I'll be tethering 3 CATs though.

The only change I'm considering making is to add another container of dessicant on the low pressure side, right before it enters the booster.

I've been debating the acquisition of a bit more reliable compressor for a couple months. Slowly narrowed down the potentials until I arrived at the Altaros booster pump. And was only pushed that direction because a really good deal on a 20gallon California Air Tools (CAT) compressor popped up on local classifieds. The lady had bought it new and used it for one job, to run a paint sprayer to redo her kitchen cabinets. So, it appears to be very lightly used.

I ordered the Altaros last Monday night and it was delivered this Tuesday, so 8 days total, I ordered the non hybrid, non bottle-to-bottle version. Sheet metal box, it doesn't look like they offer the option of the plastic toolbox like they did in the past. It arrived very well packaged, having some memory foam inside the ends of the packaging. I was previously unaware but they supplied at least a partial rebuild kit with just the purchase of the compressor. I also ordered two complete reseal kits and they were present as well. A nice little bound manual was also included.

The only assembly required was to thread the male fitting for the air supply into the side of the box.

Since I wanted the booster to have a permanent home I needed to rearrange my gun room a bit. That entailed extending a shelf and moving my bottles. I like the idea of having the bottles higher than the booster but the logistics of putting heavy bottles up a wall haven't yet been addressed, so bottle are on the ground for now. I drilled a hole through the shelf right under the bleed valve to make life a bit easier. (the shelf was made from wood I scavenged during the house remodel, just wanted to point out that I'm not responsible for the atrocious stain job)

The low pressure side of my set up has 3 bleed valves: bottom of the first stage compressor, output of the first stage compressor, and the one that came with the Altaros, right where the shop air enters the booster. 25 feet of low pressure line that goes up and around other junk in the gun room, basically from one corner to the other of the room. Altaros is about 5 feet off the ground, compressor is at ground level. On the first run last night (83 minutes) I got moisture from all three bleed valves, in descending qtys (largest amount came out from the blow out at the bottom of the first stage compressor tank). The first inch or so of the silica beads within the booster changed color slightly (orange = no moisture and dark green equals saturated, per manual). No moisture was found in the fittings on the high pressure side after all was said and done. Per NWS, the relative humidity during the fill averaged 40%, but that is of course outside. The booster lives inside a well-insulated room within my garage, so likely much lower humidity.

In that 83minutes, my big 60min Drager tank went from 3900-4500psi. That works out to an increase of about 72psi/10 minutes. For reference, the F10 would increase the pressure in this same tank by 100psi every 10minutes and the Yong Heng does the same 3900-4500 run in about 15 minutes (400psi/10minutes). So, Altaros is slowest of the three options I've used.

For about the first half of that 83 minutes I was playing with the CAT's regulator pressure and the Altaros flow adjustment to arrive at the desired run/rest ratio. It started out with a 2 min run time and a 4 minute rest (40/80). Bumped the CAT's output pressure from 90psi to 110 at that point and then fiddled with the flow restrictor to eventually get 4 min run, 4 minute rest for a very conservative 50/50. It appeared to fill faster after adjustment and I think I'll have something like 80-90psi/ten minutes now that I'm at the 50/50 run/rest times. Altaros recommends 60/40 but even at 50/50 I felt like the heads on the compressor were getting a bit warm. I'll take longer fill times if it increases the longevity of the CAT. I think 90-100psi/10 minutes would be pretty feasible if I was to push the first stage to 60/40 or even 70/30, which CAT lists as the duty cycle for this specific compressor.

I babysat the system the whole time last night, but now that I've got things set up I would feel comfortable not being right there with it. I loved that about the F10 and feel it is one of the biggest pros for the booster concept. Turn it on and go about my life, no need to hang out with eye protection and ear muffs, hoping you get out of the experience unmaimed (yes, that's how I feel about the Yong Heng). The Yonger hasn't given me any reason to fear it, but that 15minutes of fill time with the Yonger is high stress; loud, obnoxious, trying to contain it (mine's a migrater), monitoring temps (water and head temp on digital read out) requiring bleeds every couple minutes and constant monitoring to prevent overfills.

As for the first stage compressor....the F10 was happy with a 6gallon 2.6cfm @90psi pancake compressor, resting 6-8 minutes for every 2 or 3 minutes that it ran. BUT I wouldn't dare try that small of a compressor with the Altaros. This 20 gallon CAT is rated for 5.3cfm @ 90psi and I don't think I'd recommend going with anything less. Just like many before me have said, the bigger the shop compressor the better, when it comes to the Altaros.

I took a page out of @Roachcreek s book and directed a box fan at the CAT's heads because I wasn't comfortable with their heat. I don't think I'll be tethering 3 CATs though.

The only change I'm considering making is to add another container of dessicant on the low pressure side, right before it enters the booster.

Last edited: