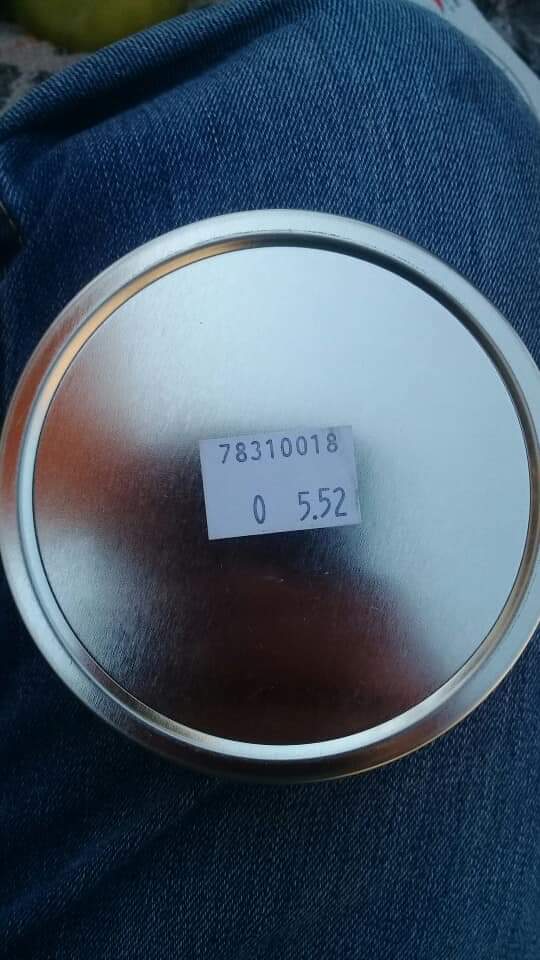

What is happening to JSB's quality control?? This is from a tin of 500 Exact Jumbo Heavy 18.13g pellets bought by a friend here in Turkey.

- Much like Google Reviews - members are allowed to create (1) unique thread for each vendor/manufacturer. You may "edit" your thread at any time to reflect any changes.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

JSB Quality Control

- Thread starter PaulB

- Start date

Here's a similar thread from a couple weeks ago asking that very same question.https://www.airgunnation.com/topic/jsb-quality-control/

Upvote 0

These are Turkish fakes. Not from JSB. I can't believe people would HONESTLY think, "consider that" JSB would release such inferior pellets. Really?!?!?! .

.

JSB/Predator International are a not in the market of screwing airgunners over.

Joe

JSB/Predator International are a not in the market of screwing airgunners over.

Joe

Upvote 0

We have had fakes in Turkey in the past and I have notified JSB at the time. They were quite good copies but errors in packaging and lead a darker colour.

As fakes these would not fool anyone for a millisecond. I am no expert but these look like a manufacturing fault. QC is not infallible but if there is a failure then the manufacturer needs to ensure it does not happen again. According to other recent posts on this forum it is possible that QC control is slipping with reports of undersized heads, weight variations etc.

As fakes these would not fool anyone for a millisecond. I am no expert but these look like a manufacturing fault. QC is not infallible but if there is a failure then the manufacturer needs to ensure it does not happen again. According to other recent posts on this forum it is possible that QC control is slipping with reports of undersized heads, weight variations etc.

Upvote 0

So you're saying that JSB would actually let that mistake get thru their QC. So these aren't possibly fakes because they are to terrible for a company making counterfeit to release

This is directly from JSB. Take it anyway you want.

JSB

Discussion on different weights and sizes of the same pellet

Regarding the differences in weight. The factory limit is up to 2.5% difference. Our test shooting proved that such a difference has no influence on accuracy of pellets.

Regarding the shape differences. I always try to explain to our customers the following… The dies (manufacturing tools) are produced in batches. There are production tolerances on all dimensions and angles of these tools. There are several components which make a set of tools producing the pellets inside our machines. Each set is specific and may differ slightly one to another (because each of the parts has its production tolerances).

Our goal is to create such a sets which will produce the most accurate pellets not as much uniform as possible. If we keep the pellets totally uniform we may not reach the best possible accuracy of the pellets which we definitely want. We prefer some differences between batches but with best possible accuracy. For identification purposes we mark them on the bottom of the tins with batch numbers and never mix it together.

Each gun is specific and may get better results with one batch then other. So the TOP shooters usually test more batches and then buy larger amount of the one which is the best for their gun.

Despite that all batches should meet our quality standard (which is mentioned on our websites) from any gun…

This is directly from JSB. Take it anyway you want.

JSB

Discussion on different weights and sizes of the same pellet

Regarding the differences in weight. The factory limit is up to 2.5% difference. Our test shooting proved that such a difference has no influence on accuracy of pellets.

Regarding the shape differences. I always try to explain to our customers the following… The dies (manufacturing tools) are produced in batches. There are production tolerances on all dimensions and angles of these tools. There are several components which make a set of tools producing the pellets inside our machines. Each set is specific and may differ slightly one to another (because each of the parts has its production tolerances).

Our goal is to create such a sets which will produce the most accurate pellets not as much uniform as possible. If we keep the pellets totally uniform we may not reach the best possible accuracy of the pellets which we definitely want. We prefer some differences between batches but with best possible accuracy. For identification purposes we mark them on the bottom of the tins with batch numbers and never mix it together.

Each gun is specific and may get better results with one batch then other. So the TOP shooters usually test more batches and then buy larger amount of the one which is the best for their gun.

Despite that all batches should meet our quality standard (which is mentioned on our websites) from any gun…

Upvote 0

No, I am not saying JSB would let it through intentionally but no QC Dept. is perfect and to say it is is naive. There always have been lemons going on sale which have been returned as soon as sold be they guns or cars for example. Misprinted money and stamps which are subject to rigorous QC have been issued and are worth fortunes.

My understanding is that JSB QC is personal rather than automated and people are fallible. Maybe with their increased production this makes it more liable that things can slip through.

From your quote JSB states that their factory limit is 2.5%. I generally weigh my pellets and will agree that about 95% meet this but in a tin of 500 I reject 20-30 on average as being light or heavy (outside of this range). I can live with that. When pellets are sold specifically as 5.51 or 5.52 or 5.53 they should be these sizes otherwise why put it on the tin.

I use JSB as they are the most consistent currently available and have no real opposition. They also cost a premium because of their reputation so they have to ensure that they maintain it.

My understanding is that JSB QC is personal rather than automated and people are fallible. Maybe with their increased production this makes it more liable that things can slip through.

From your quote JSB states that their factory limit is 2.5%. I generally weigh my pellets and will agree that about 95% meet this but in a tin of 500 I reject 20-30 on average as being light or heavy (outside of this range). I can live with that. When pellets are sold specifically as 5.51 or 5.52 or 5.53 they should be these sizes otherwise why put it on the tin.

I use JSB as they are the most consistent currently available and have no real opposition. They also cost a premium because of their reputation so they have to ensure that they maintain it.

Upvote 0

Thanks for the post...it explains about why the head sizes vary in the same tin or batches. I'll just keep shooting away.

Upvote 0