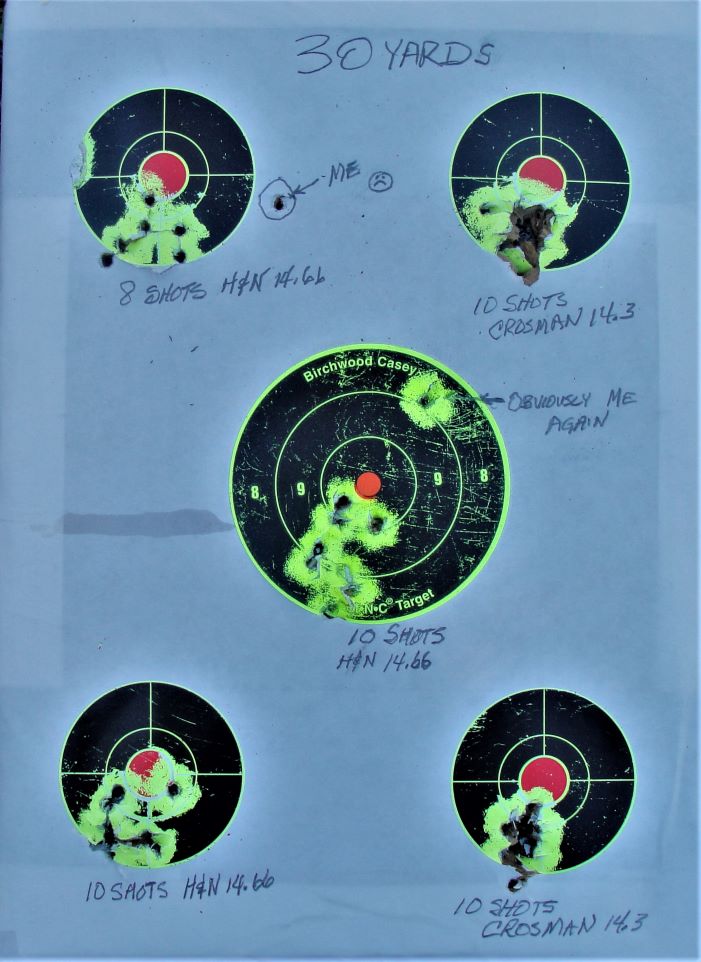

I have had my TX200 MKIII for a little over a month and although I liked the way it shot, I decided to install the new steel PG4 Vortek high output tune kit. I shot the gun after installing it yesterday and have been shooting it today. I have decided now I really love the way it shoots. I can tell the gun no longer has the spring twang sound and slight vibration feel after the shot. I think the cocking effort stayed about the same, maybe even slightly more, but not much. Here is a photo of todays shooting from 30 yards using H&N Barracuda round nose 14.66 gr. and the inexpensive Crosman 14.3 gr. pellet you can buy at Walmart. After shooting today I ordered 4 more tins of the Crosman pellets.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Installed the new steel PG4 Vortek HO tune kit in my TX200.

- Thread starter Shiloh1944

- Start date

A good tool made even better. Right on! I've had good luck with the Crosman Premier Domed and Hollow Point 14.3s. I'll get better results with other pellets, but not by much.

After reading a few postings on members using the PG4 kits from Vortek, I decided to put one in my HW95. Its on it's way. Its got a Maccari kit in currently but want to see the back to back results. Ive used the PG2 and PG3 in a couple Diana's with good results.

Thats some fine shooting to boot!

After reading a few postings on members using the PG4 kits from Vortek, I decided to put one in my HW95. Its on it's way. Its got a Maccari kit in currently but want to see the back to back results. Ive used the PG2 and PG3 in a couple Diana's with good results.

Thats some fine shooting to boot!

Upvote 0

I am guessing you have the .22 cal from the pellet weight, may I ask what velocity the rifle is shooting with the Vortek kit?

Upvote 0

Have one of those sitting here for my TX as well-can't wait to install it and try it myself. Glad you're getting good results and now know what to expect.

Upvote 0

I am guessing you have the .22 cal from the pellet weight, may I ask what velocity the rifle is shooting with the Vortek kit?

AirShot, Yes it is a .22. I am sorry but I do not have a chronograph so I don't know the velocity. It seems to be shooting a little harder over the stock spring I had in but I can't tell for certain. I wish I did have a chronograph so I could see the deviation in 10 consecutive shots.

rwsmike, It was quite simple to put in. As I have read and seen the TX200 is perhaps the easiest springer gun to work on. The kit comes with a few simple instructions so just read them and follow them. Be sure and tap out the stock steel top piece that sits on top of the stock spring in the piston as the gun will not cock if you leave it in. Some will just drop right out but mine required I tap the piston stem in my hand and jar it out. It was stuck in the piston by the lubricant.

Upvote 0

Vortek is a very nice kit. The only thing you need to make sure of is that there are no washers or top hat inside your piston. I've had issues with my TX 200 not cocking after I install the kit. After checking inside the piston...it's always something in there (either a washer or a top hat) which keeps the piston rod from latching onto the trigger sear. I have a top hat in one of my piston now. It's jammed good in there. might need to try these steps 1. brake cleaner trick (soak in brake cleaner) then try to tap the bottom of the piston rod onto a 2x4 to tap it out. 2. Hot water. remove piston seal and the two derlin bearing rings. then dunk the piston into hot water....hopefully it'll loosen the top hat then I'll use something long and narrow to fish out the top hat. 3. If 1 and 2 doesn't work, this is the last resort remove piston seal and the two derlin bearing rings. then heat up the tip of the piston on your gas stove or your propane torch. This will break the epoxy glue...unscrew the piston rod...(remove offending top hat or washer) ...then clean up old epoxy glue...re-epoxy and screw the piston rod back. Let dry for 24 hours before using.

Last edited:

Upvote 0

Wow...great ideas, but never had that much difficulty getting the top hat/ washers out! Normally continous bang the stem on a block of soft wood does the job. In my tuning days I always had better sucess with steel top hats, so you might consider the factory top hat. I would frequently get piston bounce with the plastic top hat. The extra weight of the steel top hat eliminated the piston bounce for a smoother shot cycle and slightly faster lock time. Dont be afraid to try both and then choose your preference.

Upvote 0

Nice groups indeed. My TX (.22) not ever broken in yet but getting my best groups with JSB 16.13 g Exacts. Haven't tried the Crosman yet but I hear they are very under ratedI have had my TX200 MKIII for a little over a month and although I liked the way it shot, I decided to install the new steel PG4 Vortek high output tune kit. I shot the gun after installing it yesterday and have been shooting it today. I have decided now I really love the way it shoots. I can tell the gun no longer has the spring twang sound and slight vibration feel after the shot. I think the cocking effort stayed about the same, maybe even slightly more, but not much. Here is a photo of todays shooting from 30 yards using H&N Barracuda round nose 14.66 gr. and the inexpensive Crosman 14.3 gr. pellet you can buy at Walmart. After shooting today I ordered 4 more tins of the Crosman pellets.

View attachment 180204

Upvote 0

Vortek pg4 ruined my hw95. The cocking shoe damage the spring guide that is obviously too big. Other people mentioned making sure you have the new cocking shoe. Mine already had the new cocking shoe still didn’t clear it . Grinding was so bad it destroyed the kit. I tried 4 different attempts to remedy the issue and nothing worked. Wasted over $100 and now after talking it completely apart so many times the gun ended up with scratches in the blueing. Never going to buy vortek crap again.

Upvote 0

I had to make the opening for the cocking lever longer when I installed the newer cocking shoe in my older R-9.mine has the JM kit in it.

Upvote 0

You had a grinding issue and kept using it until it damaged something, had you stopped and contacted Vortek, they could have offered a solution. You failed to stop when a problem occured, so why does this make Vortek stuff crap??Vortek pg4 ruined my hw95. The cocking shoe damage the spring guide that is obviously too big. Other people mentioned making sure you have the new cocking shoe. Mine already had the new cocking shoe still didn’t clear it . Grinding was so bad it destroyed the kit. I tried 4 different attempts to remedy the issue and nothing worked. Wasted over $100 and now after talking it completely apart so many times the gun ended up with scratches in the blueing. Never going to buy vortek crap again.

Upvote 0

Because there shouldn’t be so many post about how their product doesn’t fit it should actually fit. That’s how it makes him crap use your brain buddy.

Upvote 0

I did a little research before purchasing and installing the kit then, after having difficulties, I looked it up again, more thoroughly and found that there was a lot of people not just myself having grinding issues same model, same kit.

Upvote 0

And I obviously didn’t keep using it. The damage happened pretty quick.

The damage was an immediate did I ever say I kept using it.You had a grinding issue and kept using it until it damaged something, had you stopped and contacted Vortek, they could have offered a solution. You failed to stop when a problem occured, so why does this make Vortek stuff crap??

Upvote 0

As a toolmaker for 50 years and more experience in metal to metal contact and wear than you will ever know, I can tell you for positive it didn't happen instantly !!

Upvote 0

Now, tell me that can’t happen by just breaking the barrel once. You need another 50 years buddy. Thin metal making contact with the cocking shoe.

Upvote 0

That didn't happen with one cocking stroke for sure !!!! You might get others to believe that but anyone with metal working experience will know better...

Upvote 0