After reading, researching, watching videos, and asking questions I was led to this product. It’s a pretty straight forward system designed to sort pellets by head size.

Assembly was quick and easy. It comes with everything needed to assemble except a screwdriver and you can get away with not using one. Instructions are easy and the company owner, Jerry Cupples, is thorough in his explanation.

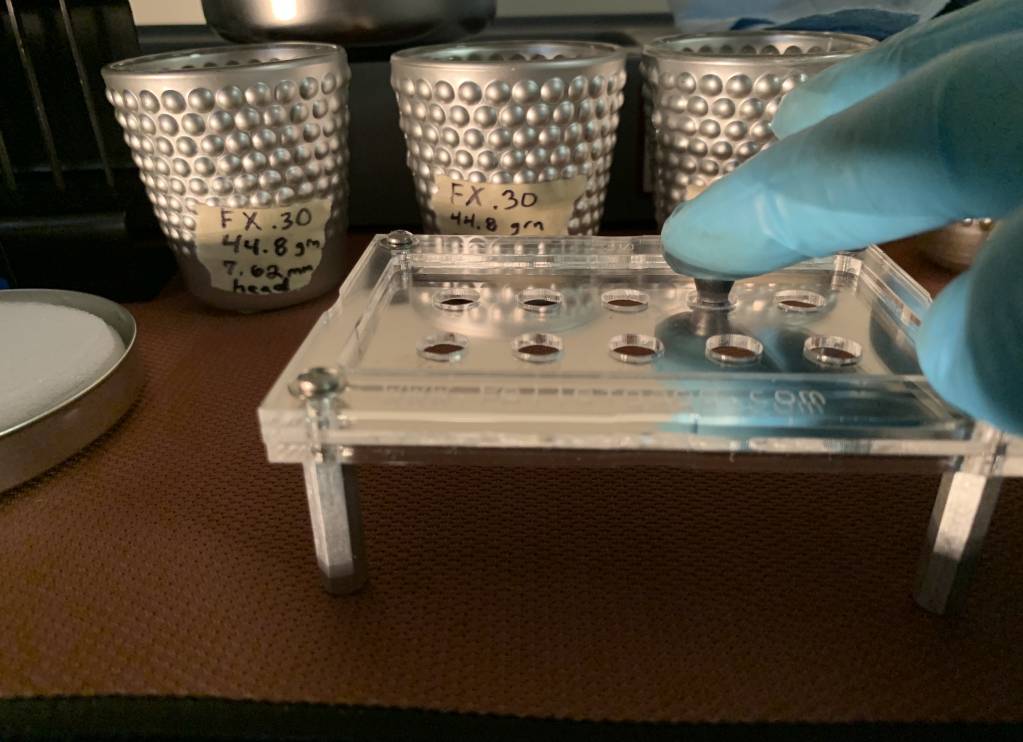

Drop a pellet in and be sure it is vertical. The pellet should freely fall through the closest sized hole. No need to force them. If it falls through really easily try using the next smallest hole until the pellet doesn’t fall into it. I have been rotating the pellets and using very light pressure on the skirts if they drop with the slightest pressure, I think that is acceptable.

Once the head falls through the skirt will catch on the gauge and the pellet will be suspended in the gauge.

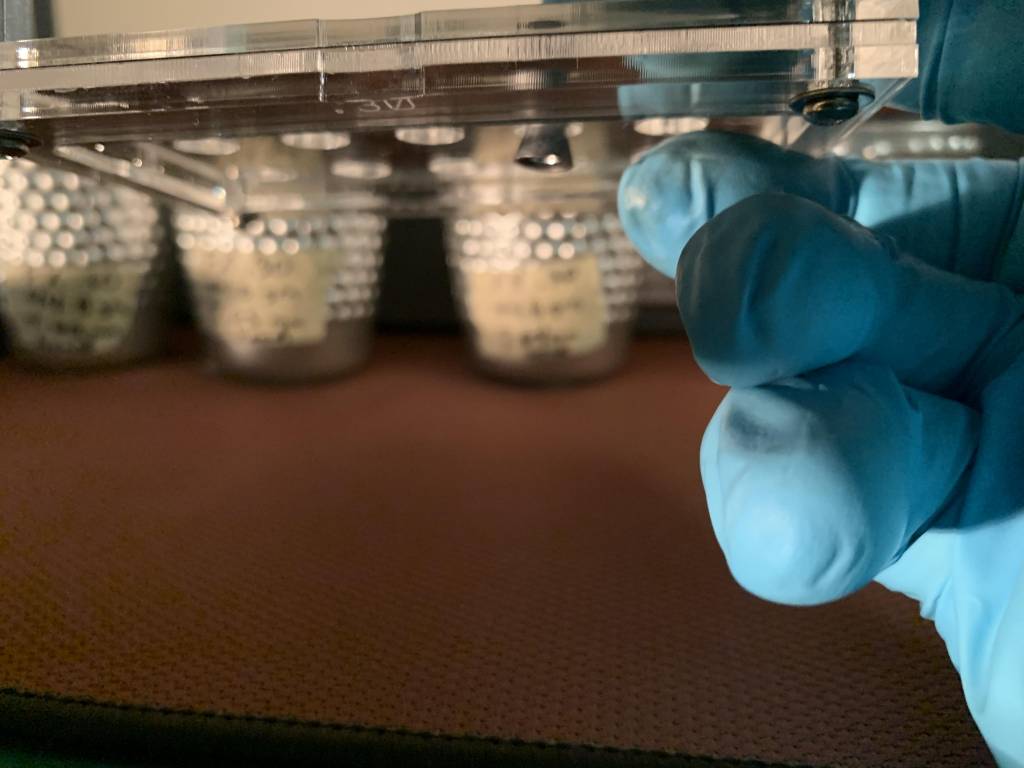

To remove the pellet I’m flipping it upside down, grabbing the skirt firmly, and gently removing it.

This is difficult to demonstrate one-handed.

Next the pellet goes into the appropriately labeled container.

This is my first time doing this. I’m hoping to get better results. I need that first shot to be a good one. If you’ve seen my posts with pictures of my groups, it’s obvious that I also need practice. This should help eliminate flyers so I can better focus on improving my shooting habits and technique.

Thank you @Airgun-Hobbyist and @Tominco for your assistance leading me to this product. Tom has videos where he goes into much more detail about his sorting process.

If interested you can find this product at www.PelletGage.com, AOA, and Baker Airguns. If you’re already ordering from the above vendors, consider ordering one with your other items. If you only want the PelletGage go to www.PelletGage.com and order direct from Jerry shipping is cheaper that way. I got mine from Jerry in 4 days via USPS during a snow storm. Oh yea and as I understand it, they’re made in the USA if that means anything to you.

Assembly was quick and easy. It comes with everything needed to assemble except a screwdriver and you can get away with not using one. Instructions are easy and the company owner, Jerry Cupples, is thorough in his explanation.

Drop a pellet in and be sure it is vertical. The pellet should freely fall through the closest sized hole. No need to force them. If it falls through really easily try using the next smallest hole until the pellet doesn’t fall into it. I have been rotating the pellets and using very light pressure on the skirts if they drop with the slightest pressure, I think that is acceptable.

Once the head falls through the skirt will catch on the gauge and the pellet will be suspended in the gauge.

To remove the pellet I’m flipping it upside down, grabbing the skirt firmly, and gently removing it.

This is difficult to demonstrate one-handed.

Next the pellet goes into the appropriately labeled container.

This is my first time doing this. I’m hoping to get better results. I need that first shot to be a good one. If you’ve seen my posts with pictures of my groups, it’s obvious that I also need practice. This should help eliminate flyers so I can better focus on improving my shooting habits and technique.

Thank you @Airgun-Hobbyist and @Tominco for your assistance leading me to this product. Tom has videos where he goes into much more detail about his sorting process.

If interested you can find this product at www.PelletGage.com, AOA, and Baker Airguns. If you’re already ordering from the above vendors, consider ordering one with your other items. If you only want the PelletGage go to www.PelletGage.com and order direct from Jerry shipping is cheaper that way. I got mine from Jerry in 4 days via USPS during a snow storm. Oh yea and as I understand it, they’re made in the USA if that means anything to you.