Hi all,

I'd like to share some key info that may not be common knowledge regarding HP air filtration.

It seems most of the posts I've seen on here regarding filtering best practices are missing something very important....need for a PMV!

Key Point: Most of the moisture removal in a proper filtration system is actually ensured by a PMV (Pressure Maintaining Valve), also called a Back Pressure Regulator.

Gap to the common practice: It seems most are relying solely on desiccants enclosed in a Tuxing style filter cartridge to remove water. While the desiccants are great at removing moisture, without a PMV, they quickly become saturated and loose effectiveness.

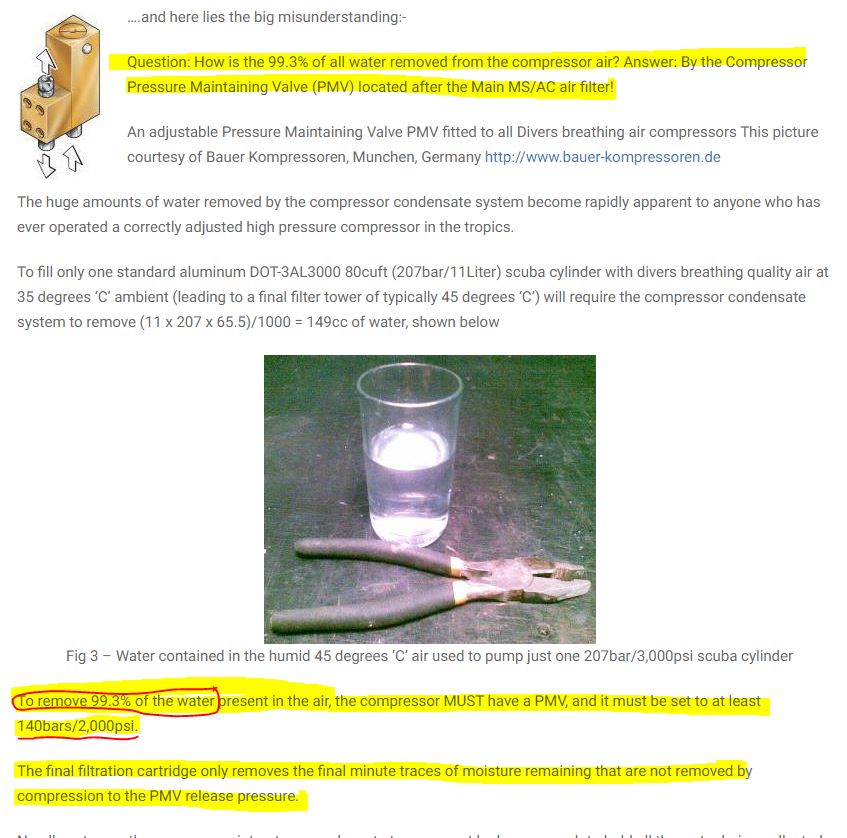

What is a PMV? Its a back pressure regulator that goes on the end of your filtration system. Its job is to ensure that no air leaves the filter (like a Tuxing / gold tube) until it reaches the set pressure of the PMV (Typically 2,000 psi). At this pressure, the air acts like a compressed sponge and is simply not capable of holding the water in suspension. Based on information from www.scubaengineer.com, the PMV alone ensures removal of 99.3% of the water!!! Here's the link if you'd like to read for yourself: https://scubaengineer.com/high_pressure_compressor_filtrat.htm

This is a big deal because it means only 0.7% of the de-humidification load then falls on the desiccant, increasing overall effectiveness and service life of the desiccant media.

A few key points:

1) This really only comes to play when you're filling either an empty tank or empty gun. If the pressure vessel you're topping off is already above 2k psi, then the moisture in the air will naturally collect at the bottom of your filtration system. Take note of that. The filter should be configured in such a way that the output hose is at the top.

2) On the high end compressor options designed for breathable air, the PMV is already built in (Airetex compressors, Bauer, etc). However, if you use the popular Yong Heng with a Tuxing style filter, you'll want to add the PMV to the output side of the Tuxing filter.

3) PMVs are available currently for about $75. However, you'll want to make sure you get quality stainless fittings rated for high pressure. I bought mine from McMaster. The Tuxing output threads are 1/8 BSPP and the threads on most PMVs are 1/4 NPT.

Below are a few pics of my setup.

Hope this helps!

I'd like to share some key info that may not be common knowledge regarding HP air filtration.

It seems most of the posts I've seen on here regarding filtering best practices are missing something very important....need for a PMV!

Key Point: Most of the moisture removal in a proper filtration system is actually ensured by a PMV (Pressure Maintaining Valve), also called a Back Pressure Regulator.

Gap to the common practice: It seems most are relying solely on desiccants enclosed in a Tuxing style filter cartridge to remove water. While the desiccants are great at removing moisture, without a PMV, they quickly become saturated and loose effectiveness.

What is a PMV? Its a back pressure regulator that goes on the end of your filtration system. Its job is to ensure that no air leaves the filter (like a Tuxing / gold tube) until it reaches the set pressure of the PMV (Typically 2,000 psi). At this pressure, the air acts like a compressed sponge and is simply not capable of holding the water in suspension. Based on information from www.scubaengineer.com, the PMV alone ensures removal of 99.3% of the water!!! Here's the link if you'd like to read for yourself: https://scubaengineer.com/high_pressure_compressor_filtrat.htm

This is a big deal because it means only 0.7% of the de-humidification load then falls on the desiccant, increasing overall effectiveness and service life of the desiccant media.

A few key points:

1) This really only comes to play when you're filling either an empty tank or empty gun. If the pressure vessel you're topping off is already above 2k psi, then the moisture in the air will naturally collect at the bottom of your filtration system. Take note of that. The filter should be configured in such a way that the output hose is at the top.

2) On the high end compressor options designed for breathable air, the PMV is already built in (Airetex compressors, Bauer, etc). However, if you use the popular Yong Heng with a Tuxing style filter, you'll want to add the PMV to the output side of the Tuxing filter.

3) PMVs are available currently for about $75. However, you'll want to make sure you get quality stainless fittings rated for high pressure. I bought mine from McMaster. The Tuxing output threads are 1/8 BSPP and the threads on most PMVs are 1/4 NPT.

Below are a few pics of my setup.

Hope this helps!